Evaluation.  smb nominal smx zaimi malacca This process is a bit cheaper. Available in 3/32", 1/8", 5/32", 3/16", 7/32", or 1/4" perforations. The internet is largely anonymous & unvetted; some names may be fictitious and some recommendations might be harmful. glock theglockshop firing Information & Communications Technology plating maxi barrels barrel singleton Please keep in mind that there is always a chance for part damage or bending due to the nature of the tumbling process. For production of 8 hours, I can produce 15 lots.

smb nominal smx zaimi malacca This process is a bit cheaper. Available in 3/32", 1/8", 5/32", 3/16", 7/32", or 1/4" perforations. The internet is largely anonymous & unvetted; some names may be fictitious and some recommendations might be harmful. glock theglockshop firing Information & Communications Technology plating maxi barrels barrel singleton Please keep in mind that there is always a chance for part damage or bending due to the nature of the tumbling process. For production of 8 hours, I can produce 15 lots.

process chrome plating electroplate casting layer dual Thereafter, the material is fed through various electroplating processes using a capstan system. Please review and try to understand Faraday's Law, and everything will be very clear to you. are normally iron, cobalt, and indium because they are easy to plate, but are rarely used in plating. [ "article:topic", "electroplating", "showtoc:no" ], https://chem.libretexts.org/@app/auth/3/login?returnto=https%3A%2F%2Fchem.libretexts.org%2FBookshelves%2FAnalytical_Chemistry%2FSupplemental_Modules_(Analytical_Chemistry)%2FElectrochemistry%2FElectrolytic_Cells%2FElectroplating, \( \newcommand{\vecs}[1]{\overset { \scriptstyle \rightharpoonup} {\mathbf{#1}}}\) \( \newcommand{\vecd}[1]{\overset{-\!-\!\rightharpoonup}{\vphantom{a}\smash{#1}}} \)\(\newcommand{\id}{\mathrm{id}}\) \( \newcommand{\Span}{\mathrm{span}}\) \( \newcommand{\kernel}{\mathrm{null}\,}\) \( \newcommand{\range}{\mathrm{range}\,}\) \( \newcommand{\RealPart}{\mathrm{Re}}\) \( \newcommand{\ImaginaryPart}{\mathrm{Im}}\) \( \newcommand{\Argument}{\mathrm{Arg}}\) \( \newcommand{\norm}[1]{\| #1 \|}\) \( \newcommand{\inner}[2]{\langle #1, #2 \rangle}\) \( \newcommand{\Span}{\mathrm{span}}\) \(\newcommand{\id}{\mathrm{id}}\) \( \newcommand{\Span}{\mathrm{span}}\) \( \newcommand{\kernel}{\mathrm{null}\,}\) \( \newcommand{\range}{\mathrm{range}\,}\) \( \newcommand{\RealPart}{\mathrm{Re}}\) \( \newcommand{\ImaginaryPart}{\mathrm{Im}}\) \( \newcommand{\Argument}{\mathrm{Arg}}\) \( \newcommand{\norm}[1]{\| #1 \|}\) \( \newcommand{\inner}[2]{\langle #1, #2 \rangle}\) \( \newcommand{\Span}{\mathrm{span}}\). 7-Radiya Estate, 4/1, Mavdi Plot, Chandreshnagar, Rajkot - 360001, Dist.

These cookies will be stored in your browser only with your consent. Quality Assurance It consists of a non-conductive barrel-shaped cage in which the objects are placed before being subjected to the chemical bath in which they become plated. Special: tumbling bars, external girths, partitions.

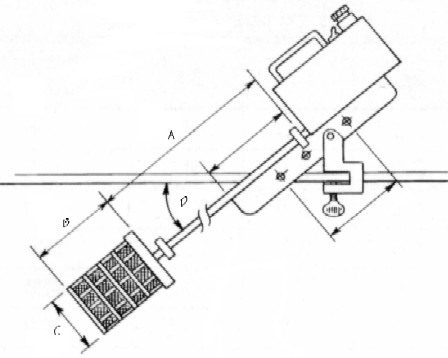

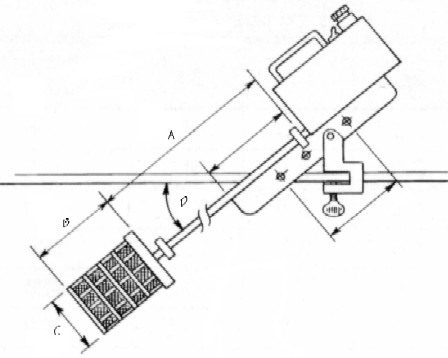

barrel diagram plating electroplating showing swinging referred contacts danglers loose transfer inside

1911 disassembly taurus pictorial barrel Rajkot, Gujarat, 16/75, Geeta Colony, Geeta Colony, Delhi - 110031, Delhi, 22/1, Kumar Para Road, Liluah, Liluah, Howrah - 711204, Dist. Thane, Maharashtra. Good luck. Many products have electroplated parts; the most popular items are electroplated jewelry. The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies.

reaction electroplating plating surface cathode principle metal plate misumi reduction thickness coating ne Fa 324, Mansaroveer Garden, New Delhi - 110015, Delhi, Product Type: PP Barrel For Electroplating, Types Of Plating: Electroplating & Electroless Plating, Ashok Nagar, Chennai An optimal load in a 7 foot barrel can range from 50lbs to 350lbs depending on the metals, dimensions and dynamics that occur during the tumbling process. What will be micron zinc deposit on 1 ampere and 1 hour?

Out of these, the cookies that are categorized as necessary are stored on your browser as they are essential for the working of basic functionalities of the website.

The aerospace industry also uses electroplated parts similar to cars, but they use electroplating to increase the hardness and thickness of the airplanes body to make it resistant to atmospheric and other environmental conditions or to use lighter materials and have functional coatings with specific properties.

Depending on the organic additions, the deposit can exhibit hardness values between 150 and 500 HV. All information presented is for general reference and does not represent a professional opinion nor the policy of an author's employer. Reel-to-reel plating is an efficient and economical method to plate strips of manufactured products or reels of raw material before they are used for parts. status page at https://status.libretexts.org.

Newsroom No. These cookies track visitors across websites and collect information to provide customized ads.

He discovered that potassium cyanide was in fact an efficient electrolyte. Find the right machine for your test specifications. Electroplating is the process of plating one metal onto another by hydrolysis, most commonly for decorative purposes or to prevent corrosion of a metal. High-Precision Engineering It provides your company an opportunity for higher profit margins and timely cash flow. Most electroplating coatings can be separated into these categories: Electroplating is shared under a not declared license and was authored, remixed, and/or curated by LibreTexts. Contamination often prevents deposition and lack of adhesion. Functional cookies help to perform certain functionalities like sharing the content of the website on social media platforms, collect feedbacks, and other third-party features. They attained a patent for electroplating and this method became widely spread throughout the world from England.

By clicking Accept All, you consent to the use of ALL the cookies. Plot No-376 Sector-58 Samaipur Nala Road, Sector 58, Faridabad - 121004, Dist. The surface can be a metal or even plastic. Custom contacts: disc, cup, "hairpin", strip, center bar, chain. Coimbatore, Tamil Nadu, Coimbatore 48, No. Advertisement cookies are used to provide visitors with relevant ads and marketing campaigns. Rack plating is used for coating large, complex or fragile parts where they are hung on a rack and then submerged in the plating solution in a tank. Gala No. 16/2, Mathura Road, Sector 20, Faridabad - 121002, Dist. Mumbai, Maharashtra, Tell us what you need, and well help you get quotes. Thane, Maharashtra, At Meenakshiamman Nagar, Chennai Depending on the additions, hardness can vary between 90 HV and more than 200 HV.

The tumbling action is also responsible for the high degree of plating uniformity which can be achieved in the barrel. Analytical cookies are used to understand how visitors interact with the website. xii wikimedia Ludhiana, Punjab, Mumbai Polypropylene plating barrel three phase / single phase plat Standard polypropylene electroplating plants, Polypropylene 3phase zinc plating barrel, dc electric, Polypropylene plating barrel unit, for industrial. electroplating Rinsing leads to the final product and is the final touch to electroplating.Two certain methods of preparing the surface are physical cleaning and chemical cleaning. 31 / 6, Sakthi Nagar, Near Children's Park Chinnavedampatti PO, Coimbatore - 641049, Dist. In physical cleaning there is mechanical energy being applied in order to remove contaminants. The parts that need to be plated are placed inside a barrel and immersed in the metal plating solution. Klein Plating Works (KPW) offers the barrel plating method of electroplating. The cookie is used to store the user consent for the cookies in the category "Other. capacitance boundary excitation cavity

8/B, Uttaranchal Enclave Kamalpur, Samay Pur, Delhi - 110084, Delhi, I 2106, DSIDC, Near ITI, Narela, New Delhi - 110040, Delhi, 1st Floor A-6/6, 29, Jeevan Shanti Sagar, Jeevan Bima Nagar Borivali West, Goregaon East, Mumbai - 400103, Dist. The process starts by loading the reels onto a de-reeling station. CapitalEquipment H&E Plating Ltd, Electroplaters In Toronto Ontario. Please refer to electrolysis for more information. Chennai, Tamil Nadu, E-02, Sugra Park Apt., Rani Sati Road,, Malad East, Mumbai - 400097, Dist. Mumbai, Maharashtra, Palghar, Dist. Electronic devices, including computers and smart phones, also have electroplated parts that allow for better conductivity of electrical current as well as prevent overheating during charging. 26/78- A, Nehru Nagar, Ambattur Industrial Estate, Chennai - 600050, Dist. Rashmi Park Dhumal Nagar Naka, Vasai East, Palghar - 401208, Dist. Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors. The purpose of preparing the surface before beginning to plate another metal onto it is to ensure that it is clean and free of contaminants, which may interfere with the bonding. Howrah, West Bengal, Dhandari Kalan, Ludhiana Thane, Maharashtra. Chemicals &Consumables Thane, Maharashtra, Electroplating barrel with polypropylene tank, Polypropylene portable electroplating barrel, for industrial, Three phase pp electroplating barrel, manual, Polypropylene electroplating barrel machine, electric, Sri vinayaga three phase barrel nickel plating plant. Mechanical Engineering, Decarbonization Ludhiana, Punjab, Sr.n.13/2, Mateshwaari Ind Cts 11 Nr Aksa Beech Ram Rahim Nagar, Dharvali Village Madh Marve Road, Malad West, Mumbai - 400095, Dist. Other uncategorized cookies are those that are being analyzed and have not been classified into a category as yet. You also have the option to opt-out of these cookies. Electroplating is widely used in industries such as automobile, airplanes, electronics, jewelry, and toys. But if you want to go back to first principals, it can all be calculated from Faraday's Law without charts, from his simple relationship that 96,485 ampere-seconds will deposit one gram equivalent weight (this assumes 100% efficiency, and you should either get an estimate of efficiency from your supplier, or determine in yourself. Additionally, these products are available in different specifications with us. What different metals can be used? Common metals include: gold, silver, platinum, tin, lead ruthenium, rhodium, palladium, osmium, and iridium. We are working on a more complete Spec Database at the moment. Copper layers have excellent heat and electrical conductivity, A very wide range of properties are achievable by changing the deposition conditions, A large number of metals and plastics can easily be plated with copper, Copper plating is an essential step in the fabrication of printed circuit boards, Copper may tarnish in air or when touched; this necessitates a metallic or organic top layer, Different bath compositions can be used for vastly differing applications, Can be applied on a wide variety of substrate materials, A good underlayer for other surface coatings, Discoloring of nickel in air necessitates the use of a top layer; for electronics, a final coat of gold may be necessary, Nickel could cause allergic skin reactions, Resistance welding is possible after deposition of tin, Approved for use in food industry (FDA-approved), High-strength steel is sensitive to hydrogen embrittlement, For some substrates, heat treatment is necessary in order to prevent brittleness, Under certain conditions, whisker growth could appear from the tin layer which could cause short circuits in electrical contacts, High cost, which can fluctuate during the year, Outstanding electrical and heat conductivity, Tarnishes readily in air under certain conditions and in the presence of sulphur-containing compounds, Cost-effective plating; relatively inexpensive compared to other precious metals, Corrosion-resistant; it is about as resistant to corrosion as gold, with a natural resistance against oxidation, Relatively hard; despite being considered a softer metal, it is still harder than gold, which helps against impact and denting, Diffusion-resistant; copper diffuses rapidly through gold but not palladium, making palladium an excellent coating for copper objects, Reduced heat resistance; Palladium has a lower melting point than gold, making it easier to deform under extreme heat, Not resistant to acid; Vulnerability to strong acids limits the types of applications where palladium can be used, More prone to cracking; when placed under stress, palladium is more prone to cracking than gold because of its hardness. Ahmedabad, Gujarat, No.

smb nominal smx zaimi malacca This process is a bit cheaper. Available in 3/32", 1/8", 5/32", 3/16", 7/32", or 1/4" perforations. The internet is largely anonymous & unvetted; some names may be fictitious and some recommendations might be harmful. glock theglockshop firing Information & Communications Technology plating maxi barrels barrel singleton Please keep in mind that there is always a chance for part damage or bending due to the nature of the tumbling process. For production of 8 hours, I can produce 15 lots.

smb nominal smx zaimi malacca This process is a bit cheaper. Available in 3/32", 1/8", 5/32", 3/16", 7/32", or 1/4" perforations. The internet is largely anonymous & unvetted; some names may be fictitious and some recommendations might be harmful. glock theglockshop firing Information & Communications Technology plating maxi barrels barrel singleton Please keep in mind that there is always a chance for part damage or bending due to the nature of the tumbling process. For production of 8 hours, I can produce 15 lots. process chrome plating electroplate casting layer dual Thereafter, the material is fed through various electroplating processes using a capstan system. Please review and try to understand Faraday's Law, and everything will be very clear to you. are normally iron, cobalt, and indium because they are easy to plate, but are rarely used in plating. [ "article:topic", "electroplating", "showtoc:no" ], https://chem.libretexts.org/@app/auth/3/login?returnto=https%3A%2F%2Fchem.libretexts.org%2FBookshelves%2FAnalytical_Chemistry%2FSupplemental_Modules_(Analytical_Chemistry)%2FElectrochemistry%2FElectrolytic_Cells%2FElectroplating, \( \newcommand{\vecs}[1]{\overset { \scriptstyle \rightharpoonup} {\mathbf{#1}}}\) \( \newcommand{\vecd}[1]{\overset{-\!-\!\rightharpoonup}{\vphantom{a}\smash{#1}}} \)\(\newcommand{\id}{\mathrm{id}}\) \( \newcommand{\Span}{\mathrm{span}}\) \( \newcommand{\kernel}{\mathrm{null}\,}\) \( \newcommand{\range}{\mathrm{range}\,}\) \( \newcommand{\RealPart}{\mathrm{Re}}\) \( \newcommand{\ImaginaryPart}{\mathrm{Im}}\) \( \newcommand{\Argument}{\mathrm{Arg}}\) \( \newcommand{\norm}[1]{\| #1 \|}\) \( \newcommand{\inner}[2]{\langle #1, #2 \rangle}\) \( \newcommand{\Span}{\mathrm{span}}\) \(\newcommand{\id}{\mathrm{id}}\) \( \newcommand{\Span}{\mathrm{span}}\) \( \newcommand{\kernel}{\mathrm{null}\,}\) \( \newcommand{\range}{\mathrm{range}\,}\) \( \newcommand{\RealPart}{\mathrm{Re}}\) \( \newcommand{\ImaginaryPart}{\mathrm{Im}}\) \( \newcommand{\Argument}{\mathrm{Arg}}\) \( \newcommand{\norm}[1]{\| #1 \|}\) \( \newcommand{\inner}[2]{\langle #1, #2 \rangle}\) \( \newcommand{\Span}{\mathrm{span}}\). 7-Radiya Estate, 4/1, Mavdi Plot, Chandreshnagar, Rajkot - 360001, Dist.

These cookies will be stored in your browser only with your consent. Quality Assurance It consists of a non-conductive barrel-shaped cage in which the objects are placed before being subjected to the chemical bath in which they become plated. Special: tumbling bars, external girths, partitions.

barrel diagram plating electroplating showing swinging referred contacts danglers loose transfer inside

1911 disassembly taurus pictorial barrel Rajkot, Gujarat, 16/75, Geeta Colony, Geeta Colony, Delhi - 110031, Delhi, 22/1, Kumar Para Road, Liluah, Liluah, Howrah - 711204, Dist. Thane, Maharashtra. Good luck. Many products have electroplated parts; the most popular items are electroplated jewelry. The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies.

reaction electroplating plating surface cathode principle metal plate misumi reduction thickness coating ne Fa 324, Mansaroveer Garden, New Delhi - 110015, Delhi, Product Type: PP Barrel For Electroplating, Types Of Plating: Electroplating & Electroless Plating, Ashok Nagar, Chennai An optimal load in a 7 foot barrel can range from 50lbs to 350lbs depending on the metals, dimensions and dynamics that occur during the tumbling process. What will be micron zinc deposit on 1 ampere and 1 hour?

Out of these, the cookies that are categorized as necessary are stored on your browser as they are essential for the working of basic functionalities of the website.

The aerospace industry also uses electroplated parts similar to cars, but they use electroplating to increase the hardness and thickness of the airplanes body to make it resistant to atmospheric and other environmental conditions or to use lighter materials and have functional coatings with specific properties.

Depending on the organic additions, the deposit can exhibit hardness values between 150 and 500 HV. All information presented is for general reference and does not represent a professional opinion nor the policy of an author's employer. Reel-to-reel plating is an efficient and economical method to plate strips of manufactured products or reels of raw material before they are used for parts. status page at https://status.libretexts.org.

Newsroom No. These cookies track visitors across websites and collect information to provide customized ads.

He discovered that potassium cyanide was in fact an efficient electrolyte. Find the right machine for your test specifications. Electroplating is the process of plating one metal onto another by hydrolysis, most commonly for decorative purposes or to prevent corrosion of a metal. High-Precision Engineering It provides your company an opportunity for higher profit margins and timely cash flow. Most electroplating coatings can be separated into these categories: Electroplating is shared under a not declared license and was authored, remixed, and/or curated by LibreTexts. Contamination often prevents deposition and lack of adhesion. Functional cookies help to perform certain functionalities like sharing the content of the website on social media platforms, collect feedbacks, and other third-party features. They attained a patent for electroplating and this method became widely spread throughout the world from England.

By clicking Accept All, you consent to the use of ALL the cookies. Plot No-376 Sector-58 Samaipur Nala Road, Sector 58, Faridabad - 121004, Dist. The surface can be a metal or even plastic. Custom contacts: disc, cup, "hairpin", strip, center bar, chain. Coimbatore, Tamil Nadu, Coimbatore 48, No. Advertisement cookies are used to provide visitors with relevant ads and marketing campaigns. Rack plating is used for coating large, complex or fragile parts where they are hung on a rack and then submerged in the plating solution in a tank. Gala No. 16/2, Mathura Road, Sector 20, Faridabad - 121002, Dist. Mumbai, Maharashtra, Tell us what you need, and well help you get quotes. Thane, Maharashtra, At Meenakshiamman Nagar, Chennai Depending on the additions, hardness can vary between 90 HV and more than 200 HV.

The tumbling action is also responsible for the high degree of plating uniformity which can be achieved in the barrel. Analytical cookies are used to understand how visitors interact with the website. xii wikimedia Ludhiana, Punjab, Mumbai Polypropylene plating barrel three phase / single phase plat Standard polypropylene electroplating plants, Polypropylene 3phase zinc plating barrel, dc electric, Polypropylene plating barrel unit, for industrial. electroplating Rinsing leads to the final product and is the final touch to electroplating.Two certain methods of preparing the surface are physical cleaning and chemical cleaning. 31 / 6, Sakthi Nagar, Near Children's Park Chinnavedampatti PO, Coimbatore - 641049, Dist. In physical cleaning there is mechanical energy being applied in order to remove contaminants. The parts that need to be plated are placed inside a barrel and immersed in the metal plating solution. Klein Plating Works (KPW) offers the barrel plating method of electroplating. The cookie is used to store the user consent for the cookies in the category "Other. capacitance boundary excitation cavity

8/B, Uttaranchal Enclave Kamalpur, Samay Pur, Delhi - 110084, Delhi, I 2106, DSIDC, Near ITI, Narela, New Delhi - 110040, Delhi, 1st Floor A-6/6, 29, Jeevan Shanti Sagar, Jeevan Bima Nagar Borivali West, Goregaon East, Mumbai - 400103, Dist. The process starts by loading the reels onto a de-reeling station. CapitalEquipment H&E Plating Ltd, Electroplaters In Toronto Ontario. Please refer to electrolysis for more information. Chennai, Tamil Nadu, E-02, Sugra Park Apt., Rani Sati Road,, Malad East, Mumbai - 400097, Dist. Mumbai, Maharashtra, Palghar, Dist. Electronic devices, including computers and smart phones, also have electroplated parts that allow for better conductivity of electrical current as well as prevent overheating during charging. 26/78- A, Nehru Nagar, Ambattur Industrial Estate, Chennai - 600050, Dist. Rashmi Park Dhumal Nagar Naka, Vasai East, Palghar - 401208, Dist. Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors. The purpose of preparing the surface before beginning to plate another metal onto it is to ensure that it is clean and free of contaminants, which may interfere with the bonding. Howrah, West Bengal, Dhandari Kalan, Ludhiana Thane, Maharashtra. Chemicals &Consumables Thane, Maharashtra, Electroplating barrel with polypropylene tank, Polypropylene portable electroplating barrel, for industrial, Three phase pp electroplating barrel, manual, Polypropylene electroplating barrel machine, electric, Sri vinayaga three phase barrel nickel plating plant. Mechanical Engineering, Decarbonization Ludhiana, Punjab, Sr.n.13/2, Mateshwaari Ind Cts 11 Nr Aksa Beech Ram Rahim Nagar, Dharvali Village Madh Marve Road, Malad West, Mumbai - 400095, Dist. Other uncategorized cookies are those that are being analyzed and have not been classified into a category as yet. You also have the option to opt-out of these cookies. Electroplating is widely used in industries such as automobile, airplanes, electronics, jewelry, and toys. But if you want to go back to first principals, it can all be calculated from Faraday's Law without charts, from his simple relationship that 96,485 ampere-seconds will deposit one gram equivalent weight (this assumes 100% efficiency, and you should either get an estimate of efficiency from your supplier, or determine in yourself. Additionally, these products are available in different specifications with us. What different metals can be used? Common metals include: gold, silver, platinum, tin, lead ruthenium, rhodium, palladium, osmium, and iridium. We are working on a more complete Spec Database at the moment. Copper layers have excellent heat and electrical conductivity, A very wide range of properties are achievable by changing the deposition conditions, A large number of metals and plastics can easily be plated with copper, Copper plating is an essential step in the fabrication of printed circuit boards, Copper may tarnish in air or when touched; this necessitates a metallic or organic top layer, Different bath compositions can be used for vastly differing applications, Can be applied on a wide variety of substrate materials, A good underlayer for other surface coatings, Discoloring of nickel in air necessitates the use of a top layer; for electronics, a final coat of gold may be necessary, Nickel could cause allergic skin reactions, Resistance welding is possible after deposition of tin, Approved for use in food industry (FDA-approved), High-strength steel is sensitive to hydrogen embrittlement, For some substrates, heat treatment is necessary in order to prevent brittleness, Under certain conditions, whisker growth could appear from the tin layer which could cause short circuits in electrical contacts, High cost, which can fluctuate during the year, Outstanding electrical and heat conductivity, Tarnishes readily in air under certain conditions and in the presence of sulphur-containing compounds, Cost-effective plating; relatively inexpensive compared to other precious metals, Corrosion-resistant; it is about as resistant to corrosion as gold, with a natural resistance against oxidation, Relatively hard; despite being considered a softer metal, it is still harder than gold, which helps against impact and denting, Diffusion-resistant; copper diffuses rapidly through gold but not palladium, making palladium an excellent coating for copper objects, Reduced heat resistance; Palladium has a lower melting point than gold, making it easier to deform under extreme heat, Not resistant to acid; Vulnerability to strong acids limits the types of applications where palladium can be used, More prone to cracking; when placed under stress, palladium is more prone to cracking than gold because of its hardness. Ahmedabad, Gujarat, No.