Aeronautical and Astronautical Engineering.  Candidates on the control and instrumentation course learn about the theoretical aspects of open and closed-loop control systems, but without getting involved in the complex mathematics traditionally used to describe and analyse these systems. A stock of calibration and buffer fluids are used to create a range of readings for each measurement. Email us to add your name to our interest list. View the complete listing of Engineering and Manufacturing courses>, Back to Professional Development: Engineering homepage. In 2016, a second, advanced course was added to the sequence. For example, we would look in detail at what signals a thermocouple produces, but only very briefly at how it works. Arnold, MD 21012, Check out some of the fast-growing and highest-paying trade careers to consider based on data from the Bureau of La https://t.co/7X09XKfzcW, It all started when a 15-year old student entered the competition with an idea to aid the mobility of children https://t.co/p7oBDOSLcq, Looking for a good welding show to binge? Cancellations must be received via email at ocpe@vcu.edu. Tel: (877) 322-5800, (Save on this price with Pre-Pay-PDH Discounts! The course is extensively hands on, giving participants considerable practical experience of the devices typically found in industry. The National Council of Examiners for Engineering and Surveying grants engineering licenses and generally requires the completion of an ABET-accredited program, four years of work experience, and the passing of a state examination.

Candidates on the control and instrumentation course learn about the theoretical aspects of open and closed-loop control systems, but without getting involved in the complex mathematics traditionally used to describe and analyse these systems. A stock of calibration and buffer fluids are used to create a range of readings for each measurement. Email us to add your name to our interest list. View the complete listing of Engineering and Manufacturing courses>, Back to Professional Development: Engineering homepage. In 2016, a second, advanced course was added to the sequence. For example, we would look in detail at what signals a thermocouple produces, but only very briefly at how it works. Arnold, MD 21012, Check out some of the fast-growing and highest-paying trade careers to consider based on data from the Bureau of La https://t.co/7X09XKfzcW, It all started when a 15-year old student entered the competition with an idea to aid the mobility of children https://t.co/p7oBDOSLcq, Looking for a good welding show to binge? Cancellations must be received via email at ocpe@vcu.edu. Tel: (877) 322-5800, (Save on this price with Pre-Pay-PDH Discounts! The course is extensively hands on, giving participants considerable practical experience of the devices typically found in industry. The National Council of Examiners for Engineering and Surveying grants engineering licenses and generally requires the completion of an ABET-accredited program, four years of work experience, and the passing of a state examination.  Over 170 learning programs with over 500 hours of online training. We then show candidates how the controllers should be configured, calibrated and tuned so that they give accurate readings and behave well in dynamic situations, explaining the three terms (proportional, integral and derivative) used in common industrial control systems. This course covers similar content to our E3 and IC3 courses, but at a more conceptual level.

Over 170 learning programs with over 500 hours of online training. We then show candidates how the controllers should be configured, calibrated and tuned so that they give accurate readings and behave well in dynamic situations, explaining the three terms (proportional, integral and derivative) used in common industrial control systems. This course covers similar content to our E3 and IC3 courses, but at a more conceptual level.  His recent research work has been concentrated in the area of digital flight control systems and payload data systems for unmanned aerial vehicles. After attaining four years of documented experience, they're qualified to take the second licensing exam, Principles and Practice of Engineering specifically for control systems. He has over 35 years of combined military, education, and consulting experience in engineering and has published over 85 refereed papers and book chapters. He is a United States Air Force veteran, received his BSEE in Electrical and Computer Engineering from the University of Tennessee, and has a Green Belt in Lean Manufacturing/Six Sigma from Purdue University. They also usually work during regular business hours, though extra hours might be required to meet project deadlines. Bruce retired from Rockwell Automation in December 2019.While working at Rockwell Automation, Bruce helped Dr. Klenke configure the first Industrial Automation Class at VCU in 2015 with six workstations. "Become a Controls Engineer: Education and Career Roadmap."

His recent research work has been concentrated in the area of digital flight control systems and payload data systems for unmanned aerial vehicles. After attaining four years of documented experience, they're qualified to take the second licensing exam, Principles and Practice of Engineering specifically for control systems. He has over 35 years of combined military, education, and consulting experience in engineering and has published over 85 refereed papers and book chapters. He is a United States Air Force veteran, received his BSEE in Electrical and Computer Engineering from the University of Tennessee, and has a Green Belt in Lean Manufacturing/Six Sigma from Purdue University. They also usually work during regular business hours, though extra hours might be required to meet project deadlines. Bruce retired from Rockwell Automation in December 2019.While working at Rockwell Automation, Bruce helped Dr. Klenke configure the first Industrial Automation Class at VCU in 2015 with six workstations. "Become a Controls Engineer: Education and Career Roadmap."

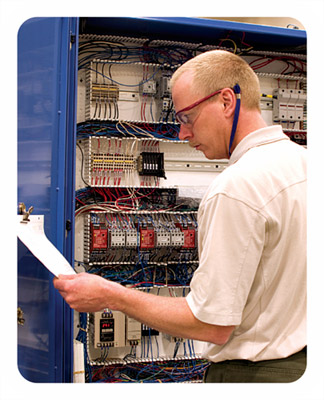

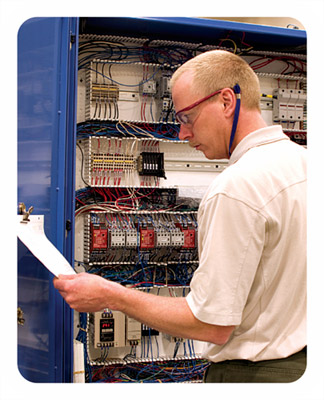

Bring ISA control systems training right to you! Virginia Commonwealth University, Updated: Engineers Project Engineers Technicians and Supervisors Involved in the Design, Maintenance and Testing of Control Systems and Industrial Automation System Integrators of OEM Equipment Staff Whose Responsibilities Include Commissioning and Troubleshooting of Control Systems Project Managers and Others Who Would Like To Know More About Control Systems and Automation. The minimum passing score is 70%. New hires may assist experienced engineers with using programming systems to integrate additional manufacturing machines into existing production lines. (Note: if you are paying by check or money order, you will be able to print it after we receive your payment.) Download our comprehensive guide to learn more about how to create a successful automated manufacturing system for your organization. The objective of this segment is to inculcate basic understanding of electrical symbols, electrical drawing conventions, and electrical design strategy. We maintain the equipment and keep it up to date for you. The focus is to understand terminology, concepts, typical equipment configurations, and common pitfalls in order to improve communication with electrical and I&C professionals. These systems involved PLC/Automation Controllers, Safety Controllers, Safety Systems, Industrial Ethernet Switches & Networking, Operator Interface Devices, S.C.A.D.A software, Historian Software, PlantPAx DCS systems, Motion Systems, Vibration Monitoring, Industrial Computers, Industrial Thin Clients, Thin Client Management Software, and VMWare Virtual Servers. document.write(document.lastModified.substring(0, Downloadable catalog of all upstream training solutions. This course provides an introduction and overview of electrical systems, instrumentation, process control, and control/safety systems typically encountered in oil and gas facilities. An error occurred trying to load this video. In the unlikely event that this program is cancelled or postponed due to insufficient enrollments or unforeseen circumstances, the university will fully refund registration fees, but cannot be held responsible for any other expenses, including change or cancellation charges to include but not limited to airlines, hotels, travel agencies, or other organizations. All Rights Reserved, This course can be customized and delivered to, Apply control laws in the automation field, Assess the performance of the various control systems components equipment, Employ your skills in the design, utilization and troubleshooting of equipment, Construction and programming requirements of PLCs, Distributed verses centralized control methods. His supplementary training in Six Sigma/Lean Manufacturing, as well as his many years of experience managing large capital projects, gives him a unique perspective asan automation educator. Get case studies, industry reports, the latest course offerings and more. Candidates learn about issues like cold junction compensation and three/four wire measurements. Candidates correct configuration and calibration errors, referring to manufacturers' manuals under the guidance of our instructor. The circuits built by candidates are then calibrated using industrial temperature calibration units. It also informs the reader about the legal andregulatory weight of the code; the fact that it's not just a voluntary standard. After participating in this course, you will be able to: Description Digest courses at your own pace from the comfort of your own home or office. In addition, ISA provides comprehensive study materials and review courses for those preparing to take theControl Systems Engineer (CSE) Professional Engineer (PE) examination. Fill out the form below to start a conversation.

Must be a high school graduate or have completed GED. You'll see the education requirements and learn about the experience you need to advance your career in engineering.

Klenke received his BSEE degree from the Virginia Military Institute in 1982 and his MSEE and Ph.D. (Electrical Engineering) degrees from the University of Virginia in 1989 and 1993 respectively. Try refreshing the page, or contact customer support. EPIC has many catalogs you can download containing courses in your area! Franks background includes more than 300 electrical and controls design projects, as well as the design and fabrication of several machines. Without consent certain enhanced features will not be available and future visits may require repeated consent, so it is recommended to accept the use of cookies. 1-800-926-8359

The control and instrumentation course requires a clean air supply and in order to simplify the logistics of the training course we use our own (silent) compressor. Comprehensive course notes are provided. This course has been supported by generous donations from Rockwell Automation and several local industries. Relevant examples and case histories further reinforce the real-world value. Or catch our breakout session https://t.co/ubLPTU6mVX, Augmented Reality / Virtual Reality Teaching Tools, Building Trades, Carpentry and Construction, Computer Aided Design and Drafting (CADD), Programmable Logic Controller (PLC) Training, Manufacturing Skill Standards Council (MSSC) Certifications, SimLog Heavy Equipment Operator Simulation, MSSC Certified Technician, Supply Chain Automation (CT-SCA), Stratasys Additive Manufacturing Certification. Get a quick view of the requirements as well Robotics teaches students the engineering and programming skills needed to create mechanical solutions to human problems or An admission advisor from each school can provide more info about: Get Started with Purdue University Global, Get Started with Southern New Hampshire University, Get Started with Southern Technical College, Get Started with University of Pennsylvania,Become a Controls Engineer: Education and Career Roadmap. With our hands-on training, you can ask questions to an experienced instructor. Petroleum Business Course Progression Map, Health, Safety, Environment Progression Map, Instrumentation, Controls and Electrical Systems Overview for Non-Electrical Engineers - ICE-21, Essential Leadership Skills for Technical Professionals, Negotiation Skills for the Petroleum Industry, Meeting Management and Facilitation for the Petroleum Industry MMF, Presentation Skills for the Petroleum Industry, Project Management in Upstream Field Development, Petroleum Project Management: Principles & Practices, Project Management for Engineering & Construction, Risk Management for Upstream Capital Projects, Construction Management for the Project Professional, Petroleum Project Changes and Claims Workshop. Students should already have experience programming. ISA also offers two outstanding certification programs for those working with control systems:Certified Control Systems Technician (CCST)andCertified Automation Professional (CAP). Focuses on programming techniques rather than instructions on the platform of your choice. Primer on a range of industrial automation concepts, terminology, and applications. The candidates expose this system to various step changes and we can then apply what they've learned theoretically to the practical business of making sure that step transitions are critically damped by tuning the three term parameters to suit the system's dynamics.

Fundamentals of electricity, such as voltage, current, resistance, power factor, and single/three phase power systems, Electrical specifications, such as voltage selection, load lists, and power, How to read one-line diagrams and understand the function of the components of power distribution, including transformers, switchgear, MCCs, VFDs, and power distribution, The function and considerations of infrastructure components, such as cable, conduit, cable tray, and duct banks, Awareness of the concepts behind classification of hazardous locations and equipment specifications, Safety risks and mitigation strategies for power systems, including short circuit and overcurrent protection, ground faults, shock hazards, and arc flash, Fundamentals of control systems, sensors, controllers, and final elements, Key requirements for instrument specifications such as accuracy, signal selection, process conditions, material compatibility, installation considerations, capabilities and limits, and relative cost, Basics of specification of shutdown and control valves, Control system functions, limitations, and architectures, including PLC, DCS, SIS, RTU, and SCADA; common networking systems, including Ethernet, Modbus and Fieldbus, Exposure to the typical documentation and drawings necessary for the design, specification, installation, operation and maintenance of electrical, instrumentation and control systems, Power distribution and motor control systems for oil and gas applications, Hazardous area classification for oil and gas applications, Electrical safety in industrial facilities, Programmable electronic systems (PLC, DCS, SIS, SCADA), Drawings and documentation for IE&C projects. (Processing fees are being waived through 6/30/2023.) The course notes are quite extensive and explain how the various devices are used, without getting involved in the underlying theory. What Is an Engineer in Training Certification? These course credits will help attendees earn training requirements for their associations or provincial governing bodies. Web.

Industrial control systems (ICS) are at the heart of industrial automation, playing a critical role in managing the operations of critical infrastructure, such as power grids; financial networks; and transportation, telecommunications, and manufacturing systems. Proven instructional design methodology and advanced web technology provide effective knowledge transfer for learners. Weve designed our training to be modular, customizable, and support a wide variety of platforms in order to meet your unique needs. How Do You Get an Engineer Driver Certification? Industrial pressure transmitters are then connected on to current loops and calibrated using the pressure sources. Candidates then build a simple closed-loop temperature control system, using a controller with relay outputs and thermocouple inputs. Upon successful completion of the quiz, print your Certificate of Completion instantly. This course is not a prerequisite for taking E3 or IC3, but rather a replacement for those that are not able to take both E3 and IC3. Ability is the flagship organizational management tool, combining a powerful learning and compliance management engine with a competency development and assurance engine. Covers HMI & SCADA programming and techniques on the platform of your choice.

All of ISA's control systems training courses can be taught directly at your company location throughISAOnsite Training services.

An Online Continuing Education Provider for Professional Engineers.

Candidates are then introduced to the more modern field-programmed 'smart' devices, which provide for remote calibration. Must be a high school graduate or have completed GED. This course is currently scheduled on the following date. Many instrumentation systems control processes using valves and we therefore look at the various types of control valves, I to P converters and valve positioners commonly used and how these would be connected and calibrated. Learn the fundamentals of PLC Hardware & Programming on the platform of your choice. ), Best Accredited Colleges / Become a Controls Engineer: Education and Career Roadmap. "I certainly feel more equipped to discuss instrumentation and controls than before." Contact us for details and pricing. Candidates are provided with comprehensive course notes. 2022 EPIC Educational Program Innovations Center. These engineers usually work in a comfortable office environment, but they occasionally have to travel to worksites to address problems in person. In 2015, Dr. Klenke developed the first course in Industrial Automation to be taught at VCU. In summary, the road to becoming a controls engineer includes earning a bachelor' degree, finding entry-level work, obtaining licensure, and being granted the official designation of a professional engineer. One of the flow rigs used on the control and instrumentation training course: This one uses an electrical control valve.

What is your highest level of education completed? Please note that you can log in to your account at any time to access and print your Certificate of Completion. PetroAcademy combines self-paced online training with virtual instructor-led sessions (either live, or pre-recorded). Learn More. Finally, fundamental principles and concepts of illumination are introduced. This course covers the key aspects of current instrumentation and process control technology and is designed to enable maintenance personnel to carry out commissioning, calibration and maintenance of the typical devices used for measurement and control in industrial systems. Three common types of electrical drawings are discussed. Best Accredited Colleges, 20 Oct 2021 published. Dr. Robert Klenkeis a professor in the Department of Electrical and Computer Engineering at VCU. We will respond as soon as we can. Lectures will be followed by simple hands-on exercises and problem-solving sessions.

To buy the course and take the quiz, please click on: 2022 Continuing Education & Development, Inc. 22 Stonewall Court, Woodcliff Lake, NJ 07677 This introductory noncredit course in Industrial Automation will specifically focus on the use of Programmable Logic Controllers (PLC) for manufacturing and process control. Candidates then tune these systems so that their dynamic behaviour is good. Other duties may include installation specifications and coordinating end user support. https://t.co/QPhkIMY7KC https://t.co/MBAQlfE05O, If youre at the #VTEEA Conference today, stop by our booth in the Lord Fairfax room! understand the health and safety implications of working with closed-loop control systems, identify the various methods of signal transmission, correctly connect electrical and air-powered devices, understand the equipment used in temperature, pressure, level and flow measurement, understand current loops and recognise the common output devices, correctly use a range of industrial calibration equipment, correctly connect, commission and calibrate current loop devices, temperature transmitters, pressure switches, pressure sensors, dp cells, ultrasonic level meters, load cell amplifiers, I to P converters and HART devices, understand the principles of turbidity, density, pH, and weight measurement, understand the relevance of the three terms (PID) used in controllers, identify the capabilities of controllers from their exterior markings, configure a range of industry standard electronic controllers. Our candidates are shown what the most common electronic controllers typically look like and study their markings and features (for example front panel buttons, sub-assembly cards, internal programming switches, etc). According to PayScale.com, controls engineers are paid a median salary of $76,301 as of February 2020. In this article, you'll find out how to become a controls engineer. - Facilities Engineer, United States The listings below may include sponsored content but are popular choices among our users. Weighing machines are commonly used in industrial instrumentation systems to quantify the contents of a container and we therefore look in detail at the range of 4-wire and 6-wire load cells in common use and examples of the transmitter electronics typically connected to them. and basic skills in the area of computer programming. Candidates on the control and instrumentation course then learn about the various devices used in industrial temperature measurement systems - we concentrate on thermocouples and Pt100s and their associated cabling, connectors and transmitter heads. Candidates then learn about pressure measurement: the various units used to quantify pressure and how industrial pressure measurement devices should be calibrated, using industrial pressure sources. Find Schools. 2022 International Society of Automation, Certified Automation Professional (CAP), Control Systems Engineer Technical Reference Handbook, Control Systems Engineering (CSE) Study Guide, Fifth Edition, Control Systems Engineering Exam Reference Manual: A Practical Study Guide, ISA Process Measurement & Control Division, Instrumentation maintenance and troubleshooting, Introduction to Industrial Processes, Measurement and Control (, Fundamentals of Industrial Process, Measurement\, and Control (, Developing and Applying Standard Instrumentation and Control Documentation (, Troubleshooting Instrumentation and Control Systems (, Designing and Tuning Feedback and Advanced Regulatory Control Strategies (, Designing and Applying Model-Based Control Strategies (EC60), Batch Control Using the ANSI/ISA88 Standards (, Certified Control Systems Technician (CCST) Level I Exam Review Course (, Certified Control Systems Technician (CCST) Level I Exam Online Review Course (, Certified Control Systems Technician (CCST) Level II Exam Review Course (, Certified Control Systems Technician (CCST) Level III Exam Review Course (, Certified Control Systems Technician (CCST) Level III Exam Online Review Course (. 100% online. info@amtekcompany.com Visit the ISA Privacy Policy for more information. The course covers the basics of the underlying principles for designing, commissioning and troubleshooting control systems. Fundamental computer skills, including working with programs that have an extensive Graphical User Interface is also required. For further practice at using the pressure sources, candidates on the control and instrumentation course then connect and calibrate a range of industrial pressure switches. Edit, 9 West Cary StreetBox 842505Richmond, Virginia 23284-2505, History of Industrial Automation - Relay logic, Input Devices and Output Actuators (field devices), PLC Programming Instructions (includes timers, counters, arithmetic, move, and comparison instructions), AC Induction Motor Basics and Variable Frequency Motor Drives, PLC Programming - Function Block Diagrams, Human Machine Interface (HMI) Programming. On completion of the course, participants will be able to. Some sample pages from the course notes give an indication of this approach, the following pages describing how burden resistors are fitted to the rear panels of instruments, what industrial temperature sensors and transmitters actually look like, our own specially-designed calibration tables for thermocouples, the use of dp cells, how hydrostatic pressure measurements are converted to level measurements using pressure sensors and how manifolds are used to zero dp cells used in flow metering: Colour handouts are issued to candidates when necessary - for example when looking at the complex colour-coding systems used for thermocouple cables and connectors: The course involves connecting various devices into current loops so that candidates learn about how current loops work and how devices are connected into them.

Candidates look in detail at the devices used to measure temperature, pressure, level and flow, and briefly at control valves, load cells, turbidity, density and pH, then go on to study the devices commonly used to control industrial processes. Youwill learn the basics of PLC operation, interfacing PLCs to sensors and actuators and programming PLCs for basic control tasks. Spatial Data Scientist: Job Description & Salary, Tooling Engineer: Job Description & Salary, Becoming a Sports Physical Therapist: Education, Degrees & Careers, Become a Catholic Priest Step-by-step Career Guide, College 20 Bringing Wikipedia Into the Classroom, Student Passes Calculus Clep Exam After Using Education Portals Online Videos to Study for Just Five Days, Human Resource Management Certificate Program in Colorado, Advanced Negotiations: Summary of Coursework, Animation Art & Design & Foundation for Design: Coursework Overview, Engineering, electrical engineering, or other closely related discipline, Licensure as a Professional Engineer (PE) is encouraged for some positions, At least 2-5 years of experience required for most positions, Attention to detail as well as communication, teamwork, and active-learning skills; knowledge of field-specific software, operating systems, and analysis; ability to use related tools, such as signal generators and other electronic equipment; familiarity with reading blueprints and other engineering techniques. Controls engineers develop, test, and implement automation, control, and processing systems, such as those used for electrical or water control. Join Now! Upon passing, individuals are called professional engineers.

Our equipment will save your company hundreds of thousands of dollars from buying training stations. This course is a combination of Course 510 and Course 515. VCU Alumni can enter promo code ALUMNI to save 10% (a $349.50 savings). Some control engineers, such as those who do government work in electrical engineering, can benefit from licensure. Continuing and Professional Education Readers are advised on how to enhance their knowledge of the code and why interpretation of the more profound aspects and interpretation of the code should be conducted by experienced electrical engineers. A degree in engineering is helpful, but not required. They may review blueprints, meet with contractors, and resolve issues to ensure that a client's project is correct. Track your progress with the discipline progression map. This course is intended for engineers, techniciansor supervisorswho work in the area of industrial automation, but do not have in-depth knowledge of PLCs, including how they are deployed, programmedor operated. Thus far, over 100 VCU engineering undergraduates and graduate students have taken the Industrial Automation courses.Dr. Our expert consultants can help you build a controls training curriculum that provideshands-on trainingon the basic wiring and troubleshooting of an electrical controls system. 29 Jul 2022 accessed. He joined the faculty in the Department of Electrical Engineering at VCU as an associate professor in 1998.

Candidates on the control and instrumentation course learn about the theoretical aspects of open and closed-loop control systems, but without getting involved in the complex mathematics traditionally used to describe and analyse these systems. A stock of calibration and buffer fluids are used to create a range of readings for each measurement. Email us to add your name to our interest list. View the complete listing of Engineering and Manufacturing courses>, Back to Professional Development: Engineering homepage. In 2016, a second, advanced course was added to the sequence. For example, we would look in detail at what signals a thermocouple produces, but only very briefly at how it works. Arnold, MD 21012, Check out some of the fast-growing and highest-paying trade careers to consider based on data from the Bureau of La https://t.co/7X09XKfzcW, It all started when a 15-year old student entered the competition with an idea to aid the mobility of children https://t.co/p7oBDOSLcq, Looking for a good welding show to binge? Cancellations must be received via email at ocpe@vcu.edu. Tel: (877) 322-5800, (Save on this price with Pre-Pay-PDH Discounts! The course is extensively hands on, giving participants considerable practical experience of the devices typically found in industry. The National Council of Examiners for Engineering and Surveying grants engineering licenses and generally requires the completion of an ABET-accredited program, four years of work experience, and the passing of a state examination.

Candidates on the control and instrumentation course learn about the theoretical aspects of open and closed-loop control systems, but without getting involved in the complex mathematics traditionally used to describe and analyse these systems. A stock of calibration and buffer fluids are used to create a range of readings for each measurement. Email us to add your name to our interest list. View the complete listing of Engineering and Manufacturing courses>, Back to Professional Development: Engineering homepage. In 2016, a second, advanced course was added to the sequence. For example, we would look in detail at what signals a thermocouple produces, but only very briefly at how it works. Arnold, MD 21012, Check out some of the fast-growing and highest-paying trade careers to consider based on data from the Bureau of La https://t.co/7X09XKfzcW, It all started when a 15-year old student entered the competition with an idea to aid the mobility of children https://t.co/p7oBDOSLcq, Looking for a good welding show to binge? Cancellations must be received via email at ocpe@vcu.edu. Tel: (877) 322-5800, (Save on this price with Pre-Pay-PDH Discounts! The course is extensively hands on, giving participants considerable practical experience of the devices typically found in industry. The National Council of Examiners for Engineering and Surveying grants engineering licenses and generally requires the completion of an ABET-accredited program, four years of work experience, and the passing of a state examination.  Over 170 learning programs with over 500 hours of online training. We then show candidates how the controllers should be configured, calibrated and tuned so that they give accurate readings and behave well in dynamic situations, explaining the three terms (proportional, integral and derivative) used in common industrial control systems. This course covers similar content to our E3 and IC3 courses, but at a more conceptual level.

Over 170 learning programs with over 500 hours of online training. We then show candidates how the controllers should be configured, calibrated and tuned so that they give accurate readings and behave well in dynamic situations, explaining the three terms (proportional, integral and derivative) used in common industrial control systems. This course covers similar content to our E3 and IC3 courses, but at a more conceptual level.  His recent research work has been concentrated in the area of digital flight control systems and payload data systems for unmanned aerial vehicles. After attaining four years of documented experience, they're qualified to take the second licensing exam, Principles and Practice of Engineering specifically for control systems. He has over 35 years of combined military, education, and consulting experience in engineering and has published over 85 refereed papers and book chapters. He is a United States Air Force veteran, received his BSEE in Electrical and Computer Engineering from the University of Tennessee, and has a Green Belt in Lean Manufacturing/Six Sigma from Purdue University. They also usually work during regular business hours, though extra hours might be required to meet project deadlines. Bruce retired from Rockwell Automation in December 2019.While working at Rockwell Automation, Bruce helped Dr. Klenke configure the first Industrial Automation Class at VCU in 2015 with six workstations. "Become a Controls Engineer: Education and Career Roadmap."

His recent research work has been concentrated in the area of digital flight control systems and payload data systems for unmanned aerial vehicles. After attaining four years of documented experience, they're qualified to take the second licensing exam, Principles and Practice of Engineering specifically for control systems. He has over 35 years of combined military, education, and consulting experience in engineering and has published over 85 refereed papers and book chapters. He is a United States Air Force veteran, received his BSEE in Electrical and Computer Engineering from the University of Tennessee, and has a Green Belt in Lean Manufacturing/Six Sigma from Purdue University. They also usually work during regular business hours, though extra hours might be required to meet project deadlines. Bruce retired from Rockwell Automation in December 2019.While working at Rockwell Automation, Bruce helped Dr. Klenke configure the first Industrial Automation Class at VCU in 2015 with six workstations. "Become a Controls Engineer: Education and Career Roadmap." Bring ISA control systems training right to you! Virginia Commonwealth University, Updated: Engineers Project Engineers Technicians and Supervisors Involved in the Design, Maintenance and Testing of Control Systems and Industrial Automation System Integrators of OEM Equipment Staff Whose Responsibilities Include Commissioning and Troubleshooting of Control Systems Project Managers and Others Who Would Like To Know More About Control Systems and Automation. The minimum passing score is 70%. New hires may assist experienced engineers with using programming systems to integrate additional manufacturing machines into existing production lines. (Note: if you are paying by check or money order, you will be able to print it after we receive your payment.) Download our comprehensive guide to learn more about how to create a successful automated manufacturing system for your organization. The objective of this segment is to inculcate basic understanding of electrical symbols, electrical drawing conventions, and electrical design strategy. We maintain the equipment and keep it up to date for you. The focus is to understand terminology, concepts, typical equipment configurations, and common pitfalls in order to improve communication with electrical and I&C professionals. These systems involved PLC/Automation Controllers, Safety Controllers, Safety Systems, Industrial Ethernet Switches & Networking, Operator Interface Devices, S.C.A.D.A software, Historian Software, PlantPAx DCS systems, Motion Systems, Vibration Monitoring, Industrial Computers, Industrial Thin Clients, Thin Client Management Software, and VMWare Virtual Servers. document.write(document.lastModified.substring(0, Downloadable catalog of all upstream training solutions. This course provides an introduction and overview of electrical systems, instrumentation, process control, and control/safety systems typically encountered in oil and gas facilities. An error occurred trying to load this video. In the unlikely event that this program is cancelled or postponed due to insufficient enrollments or unforeseen circumstances, the university will fully refund registration fees, but cannot be held responsible for any other expenses, including change or cancellation charges to include but not limited to airlines, hotels, travel agencies, or other organizations. All Rights Reserved, This course can be customized and delivered to, Apply control laws in the automation field, Assess the performance of the various control systems components equipment, Employ your skills in the design, utilization and troubleshooting of equipment, Construction and programming requirements of PLCs, Distributed verses centralized control methods. His supplementary training in Six Sigma/Lean Manufacturing, as well as his many years of experience managing large capital projects, gives him a unique perspective asan automation educator. Get case studies, industry reports, the latest course offerings and more. Candidates learn about issues like cold junction compensation and three/four wire measurements. Candidates correct configuration and calibration errors, referring to manufacturers' manuals under the guidance of our instructor. The circuits built by candidates are then calibrated using industrial temperature calibration units. It also informs the reader about the legal andregulatory weight of the code; the fact that it's not just a voluntary standard. After participating in this course, you will be able to: Description Digest courses at your own pace from the comfort of your own home or office. In addition, ISA provides comprehensive study materials and review courses for those preparing to take theControl Systems Engineer (CSE) Professional Engineer (PE) examination. Fill out the form below to start a conversation.

Must be a high school graduate or have completed GED. You'll see the education requirements and learn about the experience you need to advance your career in engineering.

Klenke received his BSEE degree from the Virginia Military Institute in 1982 and his MSEE and Ph.D. (Electrical Engineering) degrees from the University of Virginia in 1989 and 1993 respectively. Try refreshing the page, or contact customer support. EPIC has many catalogs you can download containing courses in your area! Franks background includes more than 300 electrical and controls design projects, as well as the design and fabrication of several machines. Without consent certain enhanced features will not be available and future visits may require repeated consent, so it is recommended to accept the use of cookies. 1-800-926-8359

The control and instrumentation course requires a clean air supply and in order to simplify the logistics of the training course we use our own (silent) compressor. Comprehensive course notes are provided. This course has been supported by generous donations from Rockwell Automation and several local industries. Relevant examples and case histories further reinforce the real-world value. Or catch our breakout session https://t.co/ubLPTU6mVX, Augmented Reality / Virtual Reality Teaching Tools, Building Trades, Carpentry and Construction, Computer Aided Design and Drafting (CADD), Programmable Logic Controller (PLC) Training, Manufacturing Skill Standards Council (MSSC) Certifications, SimLog Heavy Equipment Operator Simulation, MSSC Certified Technician, Supply Chain Automation (CT-SCA), Stratasys Additive Manufacturing Certification. Get a quick view of the requirements as well Robotics teaches students the engineering and programming skills needed to create mechanical solutions to human problems or An admission advisor from each school can provide more info about: Get Started with Purdue University Global, Get Started with Southern New Hampshire University, Get Started with Southern Technical College, Get Started with University of Pennsylvania,

Fundamentals of electricity, such as voltage, current, resistance, power factor, and single/three phase power systems, Electrical specifications, such as voltage selection, load lists, and power, How to read one-line diagrams and understand the function of the components of power distribution, including transformers, switchgear, MCCs, VFDs, and power distribution, The function and considerations of infrastructure components, such as cable, conduit, cable tray, and duct banks, Awareness of the concepts behind classification of hazardous locations and equipment specifications, Safety risks and mitigation strategies for power systems, including short circuit and overcurrent protection, ground faults, shock hazards, and arc flash, Fundamentals of control systems, sensors, controllers, and final elements, Key requirements for instrument specifications such as accuracy, signal selection, process conditions, material compatibility, installation considerations, capabilities and limits, and relative cost, Basics of specification of shutdown and control valves, Control system functions, limitations, and architectures, including PLC, DCS, SIS, RTU, and SCADA; common networking systems, including Ethernet, Modbus and Fieldbus, Exposure to the typical documentation and drawings necessary for the design, specification, installation, operation and maintenance of electrical, instrumentation and control systems, Power distribution and motor control systems for oil and gas applications, Hazardous area classification for oil and gas applications, Electrical safety in industrial facilities, Programmable electronic systems (PLC, DCS, SIS, SCADA), Drawings and documentation for IE&C projects. (Processing fees are being waived through 6/30/2023.) The course notes are quite extensive and explain how the various devices are used, without getting involved in the underlying theory. What Is an Engineer in Training Certification? These course credits will help attendees earn training requirements for their associations or provincial governing bodies. Web.

Industrial control systems (ICS) are at the heart of industrial automation, playing a critical role in managing the operations of critical infrastructure, such as power grids; financial networks; and transportation, telecommunications, and manufacturing systems. Proven instructional design methodology and advanced web technology provide effective knowledge transfer for learners. Weve designed our training to be modular, customizable, and support a wide variety of platforms in order to meet your unique needs. How Do You Get an Engineer Driver Certification? Industrial pressure transmitters are then connected on to current loops and calibrated using the pressure sources. Candidates then build a simple closed-loop temperature control system, using a controller with relay outputs and thermocouple inputs. Upon successful completion of the quiz, print your Certificate of Completion instantly. This course is not a prerequisite for taking E3 or IC3, but rather a replacement for those that are not able to take both E3 and IC3. Ability is the flagship organizational management tool, combining a powerful learning and compliance management engine with a competency development and assurance engine. Covers HMI & SCADA programming and techniques on the platform of your choice.

All of ISA's control systems training courses can be taught directly at your company location throughISAOnsite Training services.

An Online Continuing Education Provider for Professional Engineers.

Candidates are then introduced to the more modern field-programmed 'smart' devices, which provide for remote calibration. Must be a high school graduate or have completed GED. This course is currently scheduled on the following date. Many instrumentation systems control processes using valves and we therefore look at the various types of control valves, I to P converters and valve positioners commonly used and how these would be connected and calibrated. Learn the fundamentals of PLC Hardware & Programming on the platform of your choice. ), Best Accredited Colleges / Become a Controls Engineer: Education and Career Roadmap. "I certainly feel more equipped to discuss instrumentation and controls than before." Contact us for details and pricing. Candidates are provided with comprehensive course notes. 2022 EPIC Educational Program Innovations Center. These engineers usually work in a comfortable office environment, but they occasionally have to travel to worksites to address problems in person. In 2015, Dr. Klenke developed the first course in Industrial Automation to be taught at VCU. In summary, the road to becoming a controls engineer includes earning a bachelor' degree, finding entry-level work, obtaining licensure, and being granted the official designation of a professional engineer. One of the flow rigs used on the control and instrumentation training course: This one uses an electrical control valve.

What is your highest level of education completed? Please note that you can log in to your account at any time to access and print your Certificate of Completion. PetroAcademy combines self-paced online training with virtual instructor-led sessions (either live, or pre-recorded). Learn More. Finally, fundamental principles and concepts of illumination are introduced. This course covers the key aspects of current instrumentation and process control technology and is designed to enable maintenance personnel to carry out commissioning, calibration and maintenance of the typical devices used for measurement and control in industrial systems. Three common types of electrical drawings are discussed. Best Accredited Colleges, 20 Oct 2021 published. Dr. Robert Klenkeis a professor in the Department of Electrical and Computer Engineering at VCU. We will respond as soon as we can. Lectures will be followed by simple hands-on exercises and problem-solving sessions.

To buy the course and take the quiz, please click on: 2022 Continuing Education & Development, Inc. 22 Stonewall Court, Woodcliff Lake, NJ 07677 This introductory noncredit course in Industrial Automation will specifically focus on the use of Programmable Logic Controllers (PLC) for manufacturing and process control. Candidates then tune these systems so that their dynamic behaviour is good. Other duties may include installation specifications and coordinating end user support. https://t.co/QPhkIMY7KC https://t.co/MBAQlfE05O, If youre at the #VTEEA Conference today, stop by our booth in the Lord Fairfax room! understand the health and safety implications of working with closed-loop control systems, identify the various methods of signal transmission, correctly connect electrical and air-powered devices, understand the equipment used in temperature, pressure, level and flow measurement, understand current loops and recognise the common output devices, correctly use a range of industrial calibration equipment, correctly connect, commission and calibrate current loop devices, temperature transmitters, pressure switches, pressure sensors, dp cells, ultrasonic level meters, load cell amplifiers, I to P converters and HART devices, understand the principles of turbidity, density, pH, and weight measurement, understand the relevance of the three terms (PID) used in controllers, identify the capabilities of controllers from their exterior markings, configure a range of industry standard electronic controllers. Our candidates are shown what the most common electronic controllers typically look like and study their markings and features (for example front panel buttons, sub-assembly cards, internal programming switches, etc). According to PayScale.com, controls engineers are paid a median salary of $76,301 as of February 2020. In this article, you'll find out how to become a controls engineer. - Facilities Engineer, United States The listings below may include sponsored content but are popular choices among our users. Weighing machines are commonly used in industrial instrumentation systems to quantify the contents of a container and we therefore look in detail at the range of 4-wire and 6-wire load cells in common use and examples of the transmitter electronics typically connected to them. and basic skills in the area of computer programming. Candidates on the control and instrumentation course then learn about the various devices used in industrial temperature measurement systems - we concentrate on thermocouples and Pt100s and their associated cabling, connectors and transmitter heads. Candidates then learn about pressure measurement: the various units used to quantify pressure and how industrial pressure measurement devices should be calibrated, using industrial pressure sources. Find Schools. 2022 International Society of Automation, Certified Automation Professional (CAP), Control Systems Engineer Technical Reference Handbook, Control Systems Engineering (CSE) Study Guide, Fifth Edition, Control Systems Engineering Exam Reference Manual: A Practical Study Guide, ISA Process Measurement & Control Division, Instrumentation maintenance and troubleshooting, Introduction to Industrial Processes, Measurement and Control (, Fundamentals of Industrial Process, Measurement\, and Control (, Developing and Applying Standard Instrumentation and Control Documentation (, Troubleshooting Instrumentation and Control Systems (, Designing and Tuning Feedback and Advanced Regulatory Control Strategies (, Designing and Applying Model-Based Control Strategies (EC60), Batch Control Using the ANSI/ISA88 Standards (, Certified Control Systems Technician (CCST) Level I Exam Review Course (, Certified Control Systems Technician (CCST) Level I Exam Online Review Course (, Certified Control Systems Technician (CCST) Level II Exam Review Course (, Certified Control Systems Technician (CCST) Level III Exam Review Course (, Certified Control Systems Technician (CCST) Level III Exam Online Review Course (. 100% online. info@amtekcompany.com Visit the ISA Privacy Policy for more information. The course covers the basics of the underlying principles for designing, commissioning and troubleshooting control systems. Fundamental computer skills, including working with programs that have an extensive Graphical User Interface is also required. For further practice at using the pressure sources, candidates on the control and instrumentation course then connect and calibrate a range of industrial pressure switches. Edit, 9 West Cary StreetBox 842505Richmond, Virginia 23284-2505, History of Industrial Automation - Relay logic, Input Devices and Output Actuators (field devices), PLC Programming Instructions (includes timers, counters, arithmetic, move, and comparison instructions), AC Induction Motor Basics and Variable Frequency Motor Drives, PLC Programming - Function Block Diagrams, Human Machine Interface (HMI) Programming. On completion of the course, participants will be able to. Some sample pages from the course notes give an indication of this approach, the following pages describing how burden resistors are fitted to the rear panels of instruments, what industrial temperature sensors and transmitters actually look like, our own specially-designed calibration tables for thermocouples, the use of dp cells, how hydrostatic pressure measurements are converted to level measurements using pressure sensors and how manifolds are used to zero dp cells used in flow metering: Colour handouts are issued to candidates when necessary - for example when looking at the complex colour-coding systems used for thermocouple cables and connectors: The course involves connecting various devices into current loops so that candidates learn about how current loops work and how devices are connected into them.

Candidates look in detail at the devices used to measure temperature, pressure, level and flow, and briefly at control valves, load cells, turbidity, density and pH, then go on to study the devices commonly used to control industrial processes. Youwill learn the basics of PLC operation, interfacing PLCs to sensors and actuators and programming PLCs for basic control tasks. Spatial Data Scientist: Job Description & Salary, Tooling Engineer: Job Description & Salary, Becoming a Sports Physical Therapist: Education, Degrees & Careers, Become a Catholic Priest Step-by-step Career Guide, College 20 Bringing Wikipedia Into the Classroom, Student Passes Calculus Clep Exam After Using Education Portals Online Videos to Study for Just Five Days, Human Resource Management Certificate Program in Colorado, Advanced Negotiations: Summary of Coursework, Animation Art & Design & Foundation for Design: Coursework Overview, Engineering, electrical engineering, or other closely related discipline, Licensure as a Professional Engineer (PE) is encouraged for some positions, At least 2-5 years of experience required for most positions, Attention to detail as well as communication, teamwork, and active-learning skills; knowledge of field-specific software, operating systems, and analysis; ability to use related tools, such as signal generators and other electronic equipment; familiarity with reading blueprints and other engineering techniques. Controls engineers develop, test, and implement automation, control, and processing systems, such as those used for electrical or water control. Join Now! Upon passing, individuals are called professional engineers.

Our equipment will save your company hundreds of thousands of dollars from buying training stations. This course is a combination of Course 510 and Course 515. VCU Alumni can enter promo code ALUMNI to save 10% (a $349.50 savings). Some control engineers, such as those who do government work in electrical engineering, can benefit from licensure. Continuing and Professional Education Readers are advised on how to enhance their knowledge of the code and why interpretation of the more profound aspects and interpretation of the code should be conducted by experienced electrical engineers. A degree in engineering is helpful, but not required. They may review blueprints, meet with contractors, and resolve issues to ensure that a client's project is correct. Track your progress with the discipline progression map. This course is intended for engineers, techniciansor supervisorswho work in the area of industrial automation, but do not have in-depth knowledge of PLCs, including how they are deployed, programmedor operated. Thus far, over 100 VCU engineering undergraduates and graduate students have taken the Industrial Automation courses.Dr. Our expert consultants can help you build a controls training curriculum that provideshands-on trainingon the basic wiring and troubleshooting of an electrical controls system. 29 Jul 2022 accessed. He joined the faculty in the Department of Electrical Engineering at VCU as an associate professor in 1998.