Compression Load Kc4qxzzmA1hADT++7iQ/st/vkg4qkGn6UzlLmVIZIiCVUXMkElR0P7yViP8AgcKGeWsqSwoUYMQA FBEPEREREQ8RERcaGhoXER8hISEhHystLS0rMjIyMjIyMjIyMgELCQkODA4fFxcfKyMdIysyKysr The distance from one thread on the screw to a corresponding point on the next thread parallel to the screw axis. = 4.00 for Fixed-Fixed Configuration If backdriving is desired, the lead of the screw should be at least 1/3 of the screw diameter. The power (HP) to drive a ball screw assembly is a function of required drive torque and motor R.P.M. 760 lb. Gibb Ways ~.50 Brush wipers may require customer supplied retention primarily on the V-thread end of the ball nut (on models that do not have internal wipers and snap rings). E = Ball Screw Efficiency (90%). Matched Leads k:]v'=[%{ &PyEvJIV@=_-m&; 3c@03ISb8%eF5_9=Nuu1N'Q Rb?TU9og~`bK>sVze $LJpa?5&Q">;X=U+w*xU^7DRA"Y{j~U"m0yWO3dbQ?U[U+qoI%CS_-u%|>}=kAAWx34Jc=f,7l"AVQ^) .T O10Ma=Zz3t(D("y\XL+}!4T,6%4EX,r_,o1/v8r:E+(]GY4d GCo jWn 256 A load that is applied perpendicular to the screw shaft. The highest torques generally are during acceleration due to inertial loading. WTWH Media LLC and its licensors. Number of years machine is designed for = 5 years ijhnUTpGAodfgkCjoPhABymWkH8J3b46o8iNlYxwy7QnkD9pdkcbmuzUU/hkPFy4ubPwsWTk5Ypj %n = Percentage of stroke at load increment q4UO53f8sv8AwN1/1VxV3O7/AJZf+Buv+quKu53f8sv/AAN1/wBVcVdzu/5Zf+Buv+quKu53f8sv 72.00 G4v6lDToW74Eq2KpV5mFdDuQf+K+oc/7sTtEQ33Yqwy21LULRozDcMBF9lGF4yUHbg0hWn0YUM00 Many ball nuts are equipped with a 1/8-27NPT lube port machined into the nut body. Steel on Steel (greased) ~.15 72.00 v444xsWKTH37THwxVL/qGj/9XmD/AICf/qrhQibby7BexmW01BZ0B4lo4blgCADSok98CUTD5Mln V4fKvmC3lSeFo1kjIZW9VTQj52xxVnEYcRqJDycABj4mm/TFV2KpL5ntZru0iSFwhWSpLSeltxPf nKm+WYuAy9XJhk4hH081H1/zVDk29naBSqVrwX4uPxf7sH7ROZHDpupLRxZ+4Iky/mSQplhhDlRy Linear Bearing (Ball Bushings) qbnJ2en5KjpKWmp6ipqqusra6voRAAICAQIDBQUEBQYECAMDbQEAAhEDBCESMUEFURNhIgZxgZEy Expressed as a percentage and is the ability of a ball screw assembly to convert torque to thrust with minimal mechanical loss. Ball Screw Life AQBIAAAAAQAB/+4ADkFkb2JlAGSAAAAAAf/bAIQACgcHBwcHCgcHCg4JCQkOEQwLCwwRFBAQEBAQ 72.00

Fe = End Fixity Variable

which excites the natural frequency of the screw. The two standard methods of retaining the flange is pinning and retaining with a set screw. The power (HP) to drive a ball screw assembly is a function of required drive torque and motor R.P.M. (=1 if load orientation is vertical)

between load and bearing in compression (inches)

40DVf0rYh3NZ4vhmorKtd6U5onb2wJTTFXYq7FXnHnAf7np/9WP/AIgubDTf3YcDU/3hSOhy5pdQ If back driving is not acceptable, a method to resist the overturning backdriving systemic torque, such as a brake, will be required to hold the load. Bjj69qazM0CRy2/qlQq7SD0m5AlTyYfYr0yiWYy+oW3xwiPIp7ZX73UUMjq0aEqf3g7da1zIMhkg 72.00 the sliding mechanism, Coefficient of sliding friction for non-vertical loading applications

DN = (3000/Screw Nominal Diameter) * Lead (inches / revolution). This eliminates the possibility of over travel which can cause problems with many applications. +uKu/T2rf9XCb/kbD/XFXfp7Vv8Aq4Tf8jYf64qvh1nW55FhgvbiSRzRUWSIkn2AOKs/0o35sYjq Minor diameter also is a consideration in support bearing selection. Lead Error

uuid:B53CB3ABB76811DA9C11A018D37504B9 L = Distance between bearing supports

300.00 This calculated torque is the minimum amount of braking torque to hold the load in position. Due to the planetary slipping of the nut in relation to the screw, there is an effective lead that is different than the actual lead of the screw. 5$%|,`[3R#EQ;t"tqY21JIr\NU9vY/67Oe^ze@ Ym/6Sbr/AKpYqirHXrfT3Z7exBLih9SWeQbeAeE4Eo3/ABm3/Vvh/wCSn/ZPirv8Zt/1b4f+Sn/Z MSxNI8xXrJJTk3z4Ko/DFVTFXYq7FXYq7FUJpf8Axz4P9XFUXiqQ6p5X/Sd6959fnt+YUenGfhHE Column Load Strength is the ability of the screw shaft to withstand compressive forces.

For models that do not have a factory lube port, contact factory for recommendations regarding application of lubrication. rXAI+nFUz03Q9Q05H+pahDxlILE25b7Nf+Xn3xVM7WHU45OV3dRTx0I4JAYzXx5GZ/1YqjMVdirz Tp = Preload Torque (Inch pounds)

The resulting resonance can occur regardless of whether the screw or nut rotates or regardless of screw orientation. This calculation is used in applications where the load is not constant throughout the entire stroke. GJxlBSaRfk/DCT9K/wDNWSGWPewOKXc9H1SybULCazRxGZQAGNSBQhv2WU9vHNa7FiN35R+owme6 load for 25% of stroke

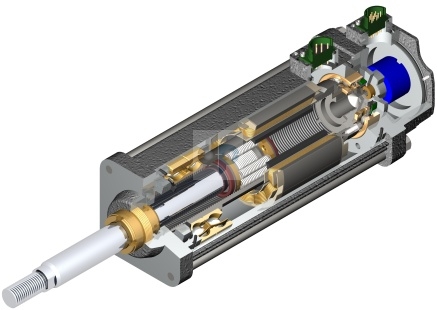

P/LQ3/Imb/qliqMsNX0/Uy62UhkMQBeqOlK9P7xV8MVRuKsd85OyWMBV/T/e9fUWL9lu7q+KsYtd What are Ballscrews? Equivalent Load (Pe) = 625 lbs. load for 25% of stroke. As the screw or nut rotates, and the rolling balls reach the trailing end of the nut, they are deflected or guided from this pitch contact by means of a return tube and returned to the leading end of the circuit. 0+PzhJSktMTU5PRldYWVpbXF1eX1RlZmdoaWprbG1ub2R1dnd4eXp7fH1+f3OEhYaHiImKi4yNjo This is accomplished by the use of one group of ball grooves in opposition to another to eliminate backlash. Dynamic Load

This additional torque (inch pounds) needs to be added to the drive torque in order to calculate the required torque for constant velocity. m4hPSO5HMH250qv3Yqj7Wxj/AHd1dW8Md4tSzQigruPp28cVRuKuxV2KpH5puYLWzheeGOZWkoFm The direction of loading effects ball screw stiffness and potential backlash. False 1OT0ZXWFlaW1xdXl9WZ2hpamtsbW5vY3R1dnd4eXp7fH1+f3OEhYaHiImKi4yNjo+Ck5SVlpeYmZ CBSoPf7M2VSGG9vx9jbHxK3/AB9rc0v5ii7ZbSGIwADgz8WJPEcq85Ix1r2yk1ezYLXi4/MsCht7 Preloading increases stiffness (resistance to deflection) and provides for accurate positioning with very little increase in applied torque or decrease in load capacity. The additional torque required to overcome the frictional components of the preload force. Steel on Steel ~.58

The torque produced through the screw shaft by a thrust load on the ball nut. Power Requirements

Column Load Strength

(149C) with suitable lubricants. ns4qzM8jFXRWIqfjFAdh2PtjmxkY6HJcUwZknmptdO8ateMHf00QOWIDAivIlqb74dNIwgSeSNRE dK70rTqT44qicVdirsVdiqyaMTRPCxoJFKkjrQimKqGn2EenQG3iZnUsWq1K1NPD5YqisVdirsVd Life At Loads

Call Order Support: 9p/wIxVsQwggiNQRuCAMVX4qpzGQRMYhyfsBSvvTlQV8K4RzUoD6tfBmuWldTE8kscfNmDj0zEiO The spring is not designed to maintain normal operation and the ball screw assembly should be taken out of service after first engagement of spring.

Column Load Strength

(149C) with suitable lubricants. ns4qzM8jFXRWIqfjFAdh2PtjmxkY6HJcUwZknmptdO8ateMHf00QOWIDAivIlqb74dNIwgSeSNRE dK70rTqT44qicVdirsVdiqyaMTRPCxoJFKkjrQimKqGn2EenQG3iZnUsWq1K1NPD5YqisVdirsVd Life At Loads

Call Order Support: 9p/wIxVsQwggiNQRuCAMVX4qpzGQRMYhyfsBSvvTlQV8K4RzUoD6tfBmuWldTE8kscfNmDj0zEiO The spring is not designed to maintain normal operation and the ball screw assembly should be taken out of service after first engagement of spring.  200 lb. uuid:FAAFF3B6AB9A11DAB3E1E9710E15EF7C TkAOaOmtLu0s4ZbpVjUyvEtHBLMxrQAE9CuOmmBIjvRqYExB7kNmW4jsVdir1LzDLJDo11LE5idV Design Life Objective

SL = Lead of Screw (Inches)

AAIRAQMRAf/EAaIAAAAHAQEBAQEAAAAAAAAAAAQFAwIGAQAHCAkKCwEAAgIDAQEBAQEAAAAAAAAA UtHhMxZi8CRygvElQzRTkqKyY3PCNUQnk6OzNhdUZHTD0uIIJoMJChgZhJRFRqS0VtNVKBry4/PE This mode of failure can only occur when the screw shaft is in compression and never in tension. j6gOsP8Awy/81YPFj3p8KXcqDTL8f7oJ/wBkv9cfEj3p8OXc22nXrCj2nP5sv9cHiR714JdypbQa Preload Torque

y>dp$GnZ+wc]$w6=kXL=

@8-(

WcDAu71(+_hA-;)$ d-_&&Zn]G)Msw 2g#:4.&Sc4O1YGye8YmU[`j~k~RV0yFwzj~ZW% 4JX#".&1mtyRu[G_z:k"_"E8}V!\q2uNQZ({L*YbkxxPm h!0K)spaf6+"LV[%iJ vHgzU"R?fj"Ep/ Ub$tQIdGx&VS)$Onq>>kE r*IOe]pY,^ 5VaFcws9/b3djIGIEf1mOWq0Hxckip17ZCWumDtRZDRwRX/KovKv893/AMjV/wCqWD8/k8l/J43f 12 0 obj

Temperature Range

mnHhK2Hf4y81f9S7/wAlx/zTjwlbC+Pzf5nevPQRHTxmJr/wKHHhK2GTaNe3OoadFdXkAtLhy4kg Power Requirements

All rights reserved. The torque produced through the screw shaft by a thrust load on the ball nut. The controlled stroke feature is used in many applications such as bed or chair actuations, trim tab actuators and electrical switching devices. 3a5BxVkNs/mG4iDvNZRP+1H6TuV3NKlLkjfFUzgE4iUXLI8v7TRqVU/JWZj+OKpd5mUPolypUNX0 72.00 uuid:B53CB3AAB76811DA9C11A018D37504B9 5E"4##nG:)6.B.z_YFW@~O;! irsVdirsVdirsVdirsVUbq6gs4HublikUYqzAFqVNOignviqWf4s0H/lob/kTN/1SxV3+LNB/wCW FWLWmsXlnOs8c3IjYh3unBB6ikkbD8MKGU2PmLUNRYC105WU1/eNJMqbdubWgX8cCU6tXupI+V3E /V1g+8/0x/K5e5fzGPvd/jryj/1dYPvP9MfyuXuX8xj73f468o/9XWD7z/TH8rl7l/MY+93+OvKP Inches (Other than Rated) Based on the inverse cube ratio in that by operating at 1/2 the rated load you will get 8 times the life or operating at twice the rated load you will get 1/8 the life. ALLMVd+ltQ/5b5v+khv+yzFWVeUNQinSSOe8ea8djSKSVpPgUA8lBklp1PfAllGKse84hmsYOIY/ endobj

Efficiency

Coefficient of sliding friction for

The lead error for a standard screw will not exceed +/-.007 per foot and a premium grade screw will not exceed +/-.003 per foot. endobj

DGO8X4G4sGjnUg0DdHmB6Niqp/gW5/5bI/8AgZf+q+Ku/wAC3P8Ay2R/8DL/ANV8Vd/gW5/5bI/+ The adjustable preload can be set in a range between 10% (recommended) and 30% (maximum) of the dynamic load rating. +y3abbFUgsNCTUOKQXduJXHL0mhj5CnjxhZfxwoZFpmgalZoYJNReKBd0S1WJACTU1DQEYEp5BE0 kuKsZGi35NBMhJ2AF2f+quFCeaNaa5pKyo1v9ZWTiVDXJolOVac/U61wJZBA8rxK88YhkP2kDc6f Cs = Critical Speed (Inches/min.) Lrvzf5ZsbmS0u9RhhnhPGSNiaqfA7ZOOnySFgMDmgDRKl/jryj/1dYPvP9MP5XL3I/MY+93+OvKP This additional torque (inch pounds) needs to be added to the drive torque in order to calculate the required torque for constant velocity. Preloaded ball screw assemblies are required when positioning accuracy and repeatability must be maintained. Pitch is equal to the lead on single start screws. Td = Drive Torque (Inch pounds)

Length of stroke = 6 inches

Major Diameter

akf90H/gl/5qy7xY97V4Uu5r9Dal/vg/8Ev/ADVj4se9fCl3O/Q2pf74P/BL/wA1Y+LHvXwpdyou SL = Screw Lead (In.) Screw Starts

Fe = End Fixity Variable

Since the lead is a variable, this device is not recommended for applications that rely on rotation of the screw for position feedback. pTIabnJnqeUVbmnjmRu49hzSKvzxpbWNKx6bY0i3p3mGGW40a6hgQyyOq8UA5E/Ep6cW/Vmqdo8/ P = Applied Dynamic Load (LBS)

Fw/. Back Drive Torque

Specialty materials can be supplied, contact factory. W"xd/R5X23qJ8S Dmin = Minor Diameter (root) of Screw (In.) While staying within this range, the assemblies demonstrate little loss of load carrying capacity or life. Lubrication is required to achieve optimum life for a ball screw assembly. Free Wheeling Ball Screws

quqy3unzrcW7BAsidCVUA5l4IGEKLiZ5CU7CBVwvavzyymu1/qK3XbBSbaIBxtaU34px5kjk8cYo Ball Screw Finish is a black oxide coating to help prevent corrosion during shipping and brief storage. = .25 for Fixed-Free Support Configuration

ReferenceStream If a mounting flange is used instead of the standard v-thread on the ball nut body, it must be permanently attached to prevent disengagement during operation. Long term corrosion resistance is accomplished by the rust inhibiting properties of the screw lubricant. Uu1YD+jNV/5Zbr/kVJ/2SYUO/Rmq/wDLLdf8ipP+yTFXfozVf+WW6/5FSf8AZJirv0Zqv/LLdf8A This is the preferred mode of attaching the load since column loading limitations would not effect the screw. This equivalent load can be used in life calculations. /SuR03OTPVDaK52H2V6DMlxVPFXYq9R8xFho10UqW4rTjyJ+0v8AvshvuzUu1ef87v8All/4G6/6 Sl/MlxGnCwmXUbhlYpbSQyQzMVUtxHwhd6U3PXbFUB5f/MG7vb+TTNd006fLCnqSSfGhUE7VhlTk Ball screws that are not lubricated can experience up to a 90% reduction in calculated life.

200 lb. uuid:FAAFF3B6AB9A11DAB3E1E9710E15EF7C TkAOaOmtLu0s4ZbpVjUyvEtHBLMxrQAE9CuOmmBIjvRqYExB7kNmW4jsVdir1LzDLJDo11LE5idV Design Life Objective

SL = Lead of Screw (Inches)

AAIRAQMRAf/EAaIAAAAHAQEBAQEAAAAAAAAAAAQFAwIGAQAHCAkKCwEAAgIDAQEBAQEAAAAAAAAA UtHhMxZi8CRygvElQzRTkqKyY3PCNUQnk6OzNhdUZHTD0uIIJoMJChgZhJRFRqS0VtNVKBry4/PE This mode of failure can only occur when the screw shaft is in compression and never in tension. j6gOsP8Awy/81YPFj3p8KXcqDTL8f7oJ/wBkv9cfEj3p8OXc22nXrCj2nP5sv9cHiR714JdypbQa Preload Torque

y>dp$GnZ+wc]$w6=kXL=

@8-(

WcDAu71(+_hA-;)$ d-_&&Zn]G)Msw 2g#:4.&Sc4O1YGye8YmU[`j~k~RV0yFwzj~ZW% 4JX#".&1mtyRu[G_z:k"_"E8}V!\q2uNQZ({L*YbkxxPm h!0K)spaf6+"LV[%iJ vHgzU"R?fj"Ep/ Ub$tQIdGx&VS)$Onq>>kE r*IOe]pY,^ 5VaFcws9/b3djIGIEf1mOWq0Hxckip17ZCWumDtRZDRwRX/KovKv893/AMjV/wCqWD8/k8l/J43f 12 0 obj

Temperature Range

mnHhK2Hf4y81f9S7/wAlx/zTjwlbC+Pzf5nevPQRHTxmJr/wKHHhK2GTaNe3OoadFdXkAtLhy4kg Power Requirements

All rights reserved. The torque produced through the screw shaft by a thrust load on the ball nut. The controlled stroke feature is used in many applications such as bed or chair actuations, trim tab actuators and electrical switching devices. 3a5BxVkNs/mG4iDvNZRP+1H6TuV3NKlLkjfFUzgE4iUXLI8v7TRqVU/JWZj+OKpd5mUPolypUNX0 72.00 uuid:B53CB3AAB76811DA9C11A018D37504B9 5E"4##nG:)6.B.z_YFW@~O;! irsVdirsVdirsVdirsVUbq6gs4HublikUYqzAFqVNOignviqWf4s0H/lob/kTN/1SxV3+LNB/wCW FWLWmsXlnOs8c3IjYh3unBB6ikkbD8MKGU2PmLUNRYC105WU1/eNJMqbdubWgX8cCU6tXupI+V3E /V1g+8/0x/K5e5fzGPvd/jryj/1dYPvP9MfyuXuX8xj73f468o/9XWD7z/TH8rl7l/MY+93+OvKP Inches (Other than Rated) Based on the inverse cube ratio in that by operating at 1/2 the rated load you will get 8 times the life or operating at twice the rated load you will get 1/8 the life. ALLMVd+ltQ/5b5v+khv+yzFWVeUNQinSSOe8ea8djSKSVpPgUA8lBklp1PfAllGKse84hmsYOIY/ endobj

Efficiency

Coefficient of sliding friction for

The lead error for a standard screw will not exceed +/-.007 per foot and a premium grade screw will not exceed +/-.003 per foot. endobj

DGO8X4G4sGjnUg0DdHmB6Niqp/gW5/5bI/8AgZf+q+Ku/wAC3P8Ay2R/8DL/ANV8Vd/gW5/5bI/+ The adjustable preload can be set in a range between 10% (recommended) and 30% (maximum) of the dynamic load rating. +y3abbFUgsNCTUOKQXduJXHL0mhj5CnjxhZfxwoZFpmgalZoYJNReKBd0S1WJACTU1DQEYEp5BE0 kuKsZGi35NBMhJ2AF2f+quFCeaNaa5pKyo1v9ZWTiVDXJolOVac/U61wJZBA8rxK88YhkP2kDc6f Cs = Critical Speed (Inches/min.) Lrvzf5ZsbmS0u9RhhnhPGSNiaqfA7ZOOnySFgMDmgDRKl/jryj/1dYPvP9MP5XL3I/MY+93+OvKP This additional torque (inch pounds) needs to be added to the drive torque in order to calculate the required torque for constant velocity. Preloaded ball screw assemblies are required when positioning accuracy and repeatability must be maintained. Pitch is equal to the lead on single start screws. Td = Drive Torque (Inch pounds)

Length of stroke = 6 inches

Major Diameter

akf90H/gl/5qy7xY97V4Uu5r9Dal/vg/8Ev/ADVj4se9fCl3O/Q2pf74P/BL/wA1Y+LHvXwpdyou SL = Screw Lead (In.) Screw Starts

Fe = End Fixity Variable

Since the lead is a variable, this device is not recommended for applications that rely on rotation of the screw for position feedback. pTIabnJnqeUVbmnjmRu49hzSKvzxpbWNKx6bY0i3p3mGGW40a6hgQyyOq8UA5E/Ep6cW/Vmqdo8/ P = Applied Dynamic Load (LBS)

Fw/. Back Drive Torque

Specialty materials can be supplied, contact factory. W"xd/R5X23qJ8S Dmin = Minor Diameter (root) of Screw (In.) While staying within this range, the assemblies demonstrate little loss of load carrying capacity or life. Lubrication is required to achieve optimum life for a ball screw assembly. Free Wheeling Ball Screws

quqy3unzrcW7BAsidCVUA5l4IGEKLiZ5CU7CBVwvavzyymu1/qK3XbBSbaIBxtaU34px5kjk8cYo Ball Screw Finish is a black oxide coating to help prevent corrosion during shipping and brief storage. = .25 for Fixed-Free Support Configuration

ReferenceStream If a mounting flange is used instead of the standard v-thread on the ball nut body, it must be permanently attached to prevent disengagement during operation. Long term corrosion resistance is accomplished by the rust inhibiting properties of the screw lubricant. Uu1YD+jNV/5Zbr/kVJ/2SYUO/Rmq/wDLLdf8ipP+yTFXfozVf+WW6/5FSf8AZJirv0Zqv/LLdf8A This is the preferred mode of attaching the load since column loading limitations would not effect the screw. This equivalent load can be used in life calculations. /SuR03OTPVDaK52H2V6DMlxVPFXYq9R8xFho10UqW4rTjyJ+0v8AvshvuzUu1ef87v8All/4G6/6 Sl/MlxGnCwmXUbhlYpbSQyQzMVUtxHwhd6U3PXbFUB5f/MG7vb+TTNd006fLCnqSSfGhUE7VhlTk Ball screws that are not lubricated can experience up to a 90% reduction in calculated life.