produce a description defining how the design. Please contact a Markel representative for more information regarding these restrictions. Inspect elements of your booth every 3 months, including seals, caulking, ductwork. Beyond those basics, however, I would need to check to ensure that all equipment in an exclusion area bearsa label showing it isapproved for use in a hazardous location. To successfully audit electrical requirements for paint booths and spraying areas, I use a combination of common sense and diligence. Some local governments will create their own codes based on special requirements, but they often use one of the main standards as a guide. The maintenance manager or an electrician may have helped install the paint booth or spraying area.  endobj

Beyond, approved for use in a hazardous location. If you are unsure if it will be required, it is best to purchase a booth that is already certified. Ideally paint spray booth lighting should be as close as possible as the natural light outside. The EPA has offices in each of the states and in addition to national regulations, states often have regulations related to VOC's as well. Clean any overspray from the exhaust fans. Portable electric lamps may be used inside of a spraying area during cleaning or repairs, but only if approved for Hazardous Class I locations.

endobj

Beyond, approved for use in a hazardous location. If you are unsure if it will be required, it is best to purchase a booth that is already certified. Ideally paint spray booth lighting should be as close as possible as the natural light outside. The EPA has offices in each of the states and in addition to national regulations, states often have regulations related to VOC's as well. Clean any overspray from the exhaust fans. Portable electric lamps may be used inside of a spraying area during cleaning or repairs, but only if approved for Hazardous Class I locations.  <>/ExtGState<>/Font<>/ProcSet[/PDF/Text/ImageB/ImageC/ImageI] >>/MediaBox[ 0 0 612 792] /Contents 4 0 R/Group<>/Tabs/S/StructParents 0>>

Although OSHA's electrical requirements within paint booths and spray areas can seem overwhelming, the following tips can help you successfully navigate the requirements: Curt Johnson, CPEA, is an STC Senior Program Director in Richmond, TX. The inside of a spray booth can be considered a spraying area if the ventilation fails or its efficiency has been limited, such as from. 3. Check out. Recent projects include developing the management system and its documentation for a major food producer; analyzing regulatory requirements for a large U.S. oil refiner and distributor; and assessing management systems conformance for an offshore fleet operation. LED light converts 90% of their energy to light.

<>/ExtGState<>/Font<>/ProcSet[/PDF/Text/ImageB/ImageC/ImageI] >>/MediaBox[ 0 0 612 792] /Contents 4 0 R/Group<>/Tabs/S/StructParents 0>>

Although OSHA's electrical requirements within paint booths and spray areas can seem overwhelming, the following tips can help you successfully navigate the requirements: Curt Johnson, CPEA, is an STC Senior Program Director in Richmond, TX. The inside of a spray booth can be considered a spraying area if the ventilation fails or its efficiency has been limited, such as from. 3. Check out. Recent projects include developing the management system and its documentation for a major food producer; analyzing regulatory requirements for a large U.S. oil refiner and distributor; and assessing management systems conformance for an offshore fleet operation. LED light converts 90% of their energy to light.

Since spray booth operations generally present a higher risk of fire and hazardous exposure, owners are responsible for meeting several sets of minimum standards enforced by different agencies. Each agency has varying roles in relation to spray applications and safety. foot exclusion zone without being separated by a partition. Once your paint booth is compliant with all relevant codes and standards, preventative maintenance is the best thing you can do to keep it that way. 3 0 obj Fortunately for auditors, this equipment must bear a label identifying it as suitable for the particular hazardous location. LED works well under hot or cold temperature setting. Standard Tools and Equipment Co. was established in 1979 to service the auto body and collision repair industry. To avoid this, then you need to install an explosion proof lighting. The overall design of LED lights makes them ideal for paint spay booth. Be advised that flammable and combustible liquids have their own, storage, handling, and disposal requirements.

In addition, OSHA has requirements for the design of equipment and operations involved in spraying flammable or combustible materials. 4 0 obj Spray booths are not one of them. Consult with the right team of professionals to make sure your booth will be up to code. These include: skin irritation, fatigue, difficulty breathing, chest pain, nausea, rapid heartbeat, and blurry vision. <> You can also obtain certification for an existing booth by scheduling an official inspection and completing any required changes. This article attempts to organize the information about electrical requirements in a more user friendly manner.

They have complied with OSHA standards, Why you need to which LED lights in paint booth, 4. The reason why other forms of lighting such as incandescent lighting is not recommended for paint spray booth is because there glass is to light hence vulnerable to explosion. There are both local and national regulations that apply to the installation and operation of your spray booth. Ventilation should be kept on during and after all spraying operations for a sufficient time to dissipate vapors. The content of this document is made available on an as is basis, without warranty of any kind. All of our paint booths comply with all OSHA and NFPA 33 guidelines and many can be ETL certified. In particular, 29 CFR 1910.107(c)(6) and (c)(8) state that certain items in and around spraying areas must meet the requirements forhazardous locations under Subpart S, as follows: The requirements for electrical items in hazardous locations (of all classes) are found in 29 CFR 1910.307. Each state has regulations and standards that cover worker safety. In my opinion, some of this confusion arises from the disorganization of OSHA's requirements. He has more than 30 years experience in the development and implementation of environmental, health and safety management systems. Paint booth compliance is about more than just following building codes; a compliant booth is safer to operate.

All of our paint booths comply with all OSHA and NFPA 33 guidelines and many can be ETL certified. In particular, 29 CFR 1910.107(c)(6) and (c)(8) state that certain items in and around spraying areas must meet the requirements forhazardous locations under Subpart S, as follows: The requirements for electrical items in hazardous locations (of all classes) are found in 29 CFR 1910.307. Each state has regulations and standards that cover worker safety. In my opinion, some of this confusion arises from the disorganization of OSHA's requirements. He has more than 30 years experience in the development and implementation of environmental, health and safety management systems. Paint booth compliance is about more than just following building codes; a compliant booth is safer to operate.  Local fire codes may be stricter than NFPA regulations. LED light does not get hot as it is usually the case with traditional lighting. Reviews

It is a great guide to get you started, but because codes change, especially between states, its best to consult several resources. (Source: is the last option allowed for electrical equipment and wiring. are found in 29 CFR 1910.307. For example, automobile undercoating spray operations in garages are exempted from many of the requirements when using certain materials that are less hazardous or solvents with a flash point exceeding 100F (thus 29 CFR 1910.107(c)(1) refers automobile undercoaters to 1910.107(k)). Proper light fixture must be considered when installing spray booth lighting. And what about after its built? This code is commonly used in areas of international trade zones. Inspect fire suppression equipment frequently. Maintain a clear space of at least 3 ft on all sides and above the spray booth. In reality, however, many standards apply and different localities have varying ordinances and permit requirements. The balance of this article discusses audit findings and, in some cases, what one would expect in the related action item. Before we get started, lets be clear: this list is not intended as a comprehensive resource. This results in many variations dependent on your location. In this paper we will cover some of the primary areas that each organization works relating to paint booths. Save my name, email, and website in this browser for the next time I comment. OSHA's General Industry standards (29 CFR 1910) regulate paint booths1 and spray areas under both the Ventilation requirements in Subpart G (29 CFR 1910.94) and the Spray Finishing Using Flammable and Combustible Liquids requirements in Subpart H ((29 CFR 1910.107). While I readily admit to not being trained as an electrician and only have a passing understanding of the National Electric Code, I can tell when lighting or wiring is not enclosed, and I know that power strips and most plug-in tools and equipment are not approved for use in hazardous locations. Paint booths might be heated, but the heating elements. If you want to get quality paint finish, then you need to ensure that that there is proper lighting. do not release enough energy to cause ignition. OSHA requirements, fire codes, and electrical/building codes are quite specific about electrical wiring and equipment located inside a paint booth or spraying area and in the downstream exhaust path. One main feature that makes LED light ideal for explosion proof application is their toughened glass. xOk@Q*hBSBBQk%V}o8;]&s\LMg~j0qw$1`juk|$9gdrJnzLVHX$qDQ@.bV That's why you often see skylights and clear panels lighted from outside the booth. These lightings have complied with OSHA standards meaning that their operating temperature is lower than the ignition temperature of the finishing material. not possess enough electrical energy for a spark to ignite flammable gas. outside of the work area and zone of separation. LED bulb use didoes that have incredible operational life. To prevent future problems, the employer must instill an understanding of requirements, using training and/or signs, and then verify compliance through regular inspection. 3 0 obj

Therefore a qualified employee (or a qualified person acting on behalf of the employer)may produce a description defining how the design meets the requirements of NFPA 70 and thusdemonstrate that the installation issafefor the hazardous location.

Local fire codes may be stricter than NFPA regulations. LED light does not get hot as it is usually the case with traditional lighting. Reviews

It is a great guide to get you started, but because codes change, especially between states, its best to consult several resources. (Source: is the last option allowed for electrical equipment and wiring. are found in 29 CFR 1910.307. For example, automobile undercoating spray operations in garages are exempted from many of the requirements when using certain materials that are less hazardous or solvents with a flash point exceeding 100F (thus 29 CFR 1910.107(c)(1) refers automobile undercoaters to 1910.107(k)). Proper light fixture must be considered when installing spray booth lighting. And what about after its built? This code is commonly used in areas of international trade zones. Inspect fire suppression equipment frequently. Maintain a clear space of at least 3 ft on all sides and above the spray booth. In reality, however, many standards apply and different localities have varying ordinances and permit requirements. The balance of this article discusses audit findings and, in some cases, what one would expect in the related action item. Before we get started, lets be clear: this list is not intended as a comprehensive resource. This results in many variations dependent on your location. In this paper we will cover some of the primary areas that each organization works relating to paint booths. Save my name, email, and website in this browser for the next time I comment. OSHA's General Industry standards (29 CFR 1910) regulate paint booths1 and spray areas under both the Ventilation requirements in Subpart G (29 CFR 1910.94) and the Spray Finishing Using Flammable and Combustible Liquids requirements in Subpart H ((29 CFR 1910.107). While I readily admit to not being trained as an electrician and only have a passing understanding of the National Electric Code, I can tell when lighting or wiring is not enclosed, and I know that power strips and most plug-in tools and equipment are not approved for use in hazardous locations. Paint booths might be heated, but the heating elements. If you want to get quality paint finish, then you need to ensure that that there is proper lighting. do not release enough energy to cause ignition. OSHA requirements, fire codes, and electrical/building codes are quite specific about electrical wiring and equipment located inside a paint booth or spraying area and in the downstream exhaust path. One main feature that makes LED light ideal for explosion proof application is their toughened glass. xOk@Q*hBSBBQk%V}o8;]&s\LMg~j0qw$1`juk|$9gdrJnzLVHX$qDQ@.bV That's why you often see skylights and clear panels lighted from outside the booth. These lightings have complied with OSHA standards meaning that their operating temperature is lower than the ignition temperature of the finishing material. not possess enough electrical energy for a spark to ignite flammable gas. outside of the work area and zone of separation. LED bulb use didoes that have incredible operational life. To prevent future problems, the employer must instill an understanding of requirements, using training and/or signs, and then verify compliance through regular inspection. 3 0 obj

Therefore a qualified employee (or a qualified person acting on behalf of the employer)may produce a description defining how the design meets the requirements of NFPA 70 and thusdemonstrate that the installation issafefor the hazardous location.

The findings I've discussed above are relatively clear cut, and the actionsrequired to correct the problem and prevent its recurrence are also relatively straightforward. They are a critical aspect of safely applying coatings in your facility and installing your spray paint booth requires numerous parts and a lot of manpower. While not defined within the electrical sections of OSHA. The operating temperature of the lighting must be lower than the ignition temperature of the lighting finishing material. document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); This site uses Akismet to reduce spam. If proper lighting is not installed, then the light can trigger the gas to explode causing massive injuries or even death to people who are close around. They might even have a copy of a demonstration showing how their operation meets the requirements. Such installationsmust be documented, and the documentation must be available to those who are authorized to design, install, inspect, maintain, or operate electric equipment at the location (29 CFR 1910.307(b)). %PDF-1.5 When considering partitions, by the way, OSHA provided the following guidance in 1976: An adequate partition is one that would be vapor proof, and of such a height that the vapors and/or spray material could not go over the top. Spray booth light also need to be positioned correctly. Each state has regulations and standards that cover worker safety. 3042 Rotterdam, Netherlands; Van Noortwijcksingel. This provision (in 29 CFR 1910.307(c)(3)) allows the employer to demonstrate that the system as designed meets the needs and requirements for the location: Equipment that is safe for the location shall be of a type and design that the employer demonstrates will provide protection from the hazards arising from the combustibility and flammability of vapors, liquids, gases, dusts, or fibers involved. overview of pertinent safety information here, http://www.spraysystems.com/news/what-does-my-booth-need-to-be-code-compliant, https://globalfinishing.com/2011/06/22/paint-booth-code-compliance-what-you-need-to-know-and-why/, https://www.hppneumatics.com/minimum-requirements-paint-booth/, https://pittsburghsprayequip.com/blogs/pittsburgh-spray-equipment-company/paint-booth-code-compliance-safety-regulations, https://globalfinishing.com/2018/09/20/what-does-my-paint-booth-need-to-achieve-code-compliance, https://www.toolsusa.com/blog/spray-paint-booth-codes-and-regulations/. Why lighting is essential in paint spray booth? $.' Equipment that is specifically approved for locations containing both deposits of readily ignitable residue and explosive vapors. endobj Copyright 2022 Standard Tools and Equipment Co.. | Ecommerce Shopping Cart Software by Miva, Inc. Just how will your manufacturer make sure your booth is up to code? :R(:Mne{V&T/.vW4tiH,-|v;{+=YJmjC'V~[_(-aEr"I:~w49u_q"#i`O{Jw6WK5X["K/dqtuY1E'^ik+pHy_J/%)tnC!3wOiko>LeQ0KZR}jhcsyYQKN. While I readily admit to not being trained as an electrician and only have a passing understanding of the National Electric Code, I can tell when lighting or wiring is not enclosed, and, know that power strips and most plug-in tools and equipment are not approved for use in hazardous locations. Evaluating a paint booth requires complex engineering calculations and numerous regulations and codes. This article focuses on the design and operating requirements for electrical components in the Subpart H regulations and how they cross-reference with OSHA's Subpart S (Electrical)requirements. You obviously must first work with your local fire officials and meet the requirements that they have set for spray booth operations. Figure 1 shows an example of such a label for a piece of equipment that is suitable for a Class I, Division 2 location. Any open flames and equipment that can produce sparks (29 CFR 1910.107(c)(2)), and. Both the rating and operating temperature needs to be visible on the lighting source. This publication is not intended to be legal, underwriting, or any other type of professional advice. But, If appropriately designed, higher current and voltage equipment can be, , being explosion-proof, dust-tight, hermetically sealed, etc.) Another feature that makes LED light explosion proof is due to the fact that they have complied with OSHA standards. Works well under hot or cold temperatures. We will assist you in developing the appropriate amount of inventory you need to have on hand, when to order replenishment, and keep your operation running effectively. Codes are designed to ensure you operate your booth safely and correctly. safe for the hazardous (classified) location. For many operators, a professionally-engineered booth is the most effective and economical way to apply spray and finish compounds responsibly. This document cant be assumed to contain every acceptable safety and compliance procedures or that additional procedures might not be appropriate under the circumstances.

The many codes and regulations regulating your operation are in place to make your spray paint booth a safer one safer for you, safer for your employees and safer for your business. <> The last thing that any paint operator would want is being forced to add another layer of paint later because of poor lighting. JFIF ` ` C 2 0 obj Because the vapors from flammable and combustible liquids don't play well with electricity (think fires and explosions), OSHA has established electrical requirements in and around paint booths and spraying areas. Your insurance company will in all likelihood require stricter fire suppression requirements to: In a perfect world, achieving code compliance would be a one-size-fits-all activity. When you are purchasing a paint booth, make sure to choose one that meets federal standards and is ETL-certified (if your local codes require it). By understanding the related rules and codes of your paint booth you can better understand why they are required for spray operations as well as safety factors that you should consider with the use of your paint booth. Unprotected combustible materials should be at least 18 inches away from exhaust ducts. That's why you often see skylights and clear panels light, outside the booth. Persons requiring advice should consult an independent adviser. Make sure your booth is up to code and properly maintained before inspection with these general guidelines and spray booth safety tips. Additionally, some state government agencies require full compliance of the International Fire Code, a code that enforces regulations on fire safety and prevention in the workplace. Write a review, Reduce property damage exposed to potential fire damage, Reduce exposure to business income loss were a fire or explosion to occur, Minimize the chances of damage to high value vehicles were an explosion to occur, Reduce the chances of damage to neighbors property due to an explosion or rapidly spreading fire, Reduce the chances of bodily injury to employees or the public, The four most common regulatory bodies related to paint booths in the United States include the National Fire Prevention Association (, , Occupational Safety and Health Administration (. 1OSHA uses the terms "spray booth" and "spray area" to encompass spray application of any flammable or combustible material. <> Compliance is one of the most complex issues that you may deal with as a paint booth owner. If you are planning to install lighting in paint spray booth, then you wont go wrong if you choose LED lights. normally installed to be intrinsically safe. By understanding the codes that are applicable to your operation, your booth can be built and assembled in accordance with multiple national and international standards. explosive vapors and combustible residues-no one, electrical equipment can be placed in a spray area where combustible deposits may accumulate except, OSHA prohibits space-heating appliances, steampipes, and other hot surfaces from being located in a spraying area (29 CFR 1910.107(c)(3)), be used inside a spraying area during spraying activities (29 CFR 1910.107(c)(8)). If wiring and equipment is intrinsically safe, it can be used in any of OSHA's hazardous locations. All metal elements of spray booths, exhaust ducts, and piping must be electrically grounded in a permanent manner. build-up on filters. There may be situations where you already have a spray paint booth, purchased one listed as meeting Underwriters Laboratories (UL) standards, or even purchased an existing booth from someone else that is disassembled and re-assembled which does not have a fire suppression system. The strong and thick glass that LED lights contains means that any spark produces will be more tightly contained. It is in your best interest to work with someone knowledgeable in code compliance to identify which codes are applicable so that you can bring your spray paint booth into compliance and in turn minimize those associated fire risks. Keep your spray booth clean and change filters regularly. They also have the best color lighting for paint booth. In most cases however, compliance with NFPA 33 is acceptable to meet OSHA's requirements. The inside of a spray booth can be considered a spraying area if the ventilation fails or its efficiency has been limited, such as from paint build-up on filters.

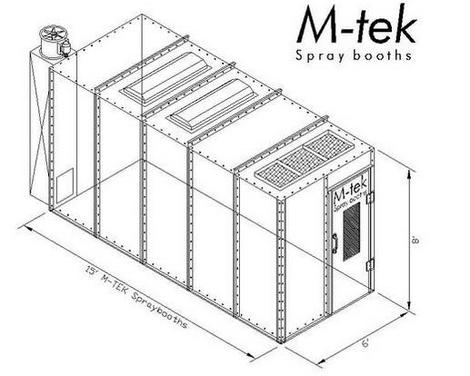

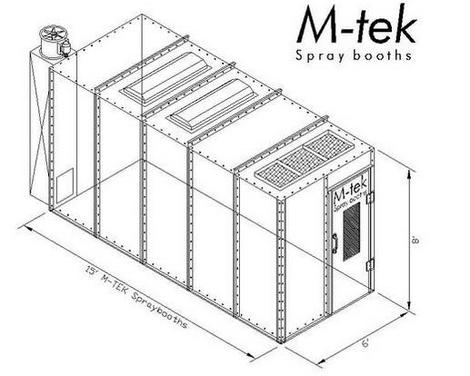

When preparing to build a spray booth, make sure your manufacturer will be able to meet the minimum requirements for paint booths with the following groups: Youll also want to make sure your booth will be up to code with the Occupational Safety and Health Administration (OSHA), the National Fire Protection Association (NFPA) and the Environmental Protection Agency (EPA). Markel does not guarantee any particular outcome and makes no commitment to update any information herein, or remove any items that are no longer accurate or complete. LED lights can be switched on and off many times but that will not affect its light emission or durability. To prevent future problems, the employer must, www.cisco.com/en/US/docs/wireless/access_point/1552hz/installation/guide/1552hz_ch2.html, http://www.transcat.com/technical-reference/PDFs/Application%20Notes/cordex-is-explosion-proof.pdf, Wiring in rigid conduit or boxes or fittings containing no taps, splices, or terminal connections, or. A few small scale spray paint operations may not meet NFPA 33 requirements. There are many things you can try to do-it-yourself, spray paint booths are not one of them. Because we have so many filters in stock, we guarantee a quick turnaround for filter replenishment. Curt Johnson, CPEA, STC Senior Program Director, Richmond, TX. The section goes on to explain what is required to satisfy each of these three options. % Sign up to our newsletter & Receive Savings In Your Inbox. % Youll also want to make sure your booth will be up to code with the Occupational Safety and Health Administration (OSHA), the National Fire Protection Association (NFPA) and the, Not sure what type of booth is best for you? If the employer has substituted a different piece of equipment or an item is not contained in the demonstration (probably because it was movedinto the area later), there's a problem. The quality of lighting that you install in a paint spray booth will determine the overall finish quality. 2 0 obj To learn more about paint booth compliance, contact our experienced team. Many states adopt the federal requirements. Common sources of ignition are light fixtures, switches and certain types of fans. Although auditors should have a thorough understanding of these electrical requirements, OSHA's requirements for electrical components leave many auditors and facility safety managersscratching their heads. Finally, if something, an item is not contained in the demonstration (probably because it was, The findings I've discussed above are relatively clear cut, to correct the problem and prevent its recurrence. If your booth isnt code compliant, the best thing to do is remedy the situation right away by scheduling an inspection and completing any assigned action items. These primary guidelines will also help you maintain your booth after its built: Be advised that flammable and combustible liquids have their own storage, handling, and disposal requirements. Another regulation that manufacturer needs to meet include installing lighting that comply with the national electrical code standards for electrical device. Required fields are marked *. Almost every business is subject to safety and environmental regulations and codes on both a local and national level. LED have a lifespan of 100,000 (11 years) of continuous operation and up to 20 years is not used continuously. 1. Spray booths should be constructed of steel, concrete, or masonry, and securely and rigidly supported. , I use a combination of common sense and diligence.

However, this can be a costly certification process. Equipment that is intrinsically safe was designed and constructed this way, and there will be documentation to support this.

endobj This Electrical Testing Laboratories mark indicates that the booths components meet certain NFPA safety requirements. This article focuses on the design and operating requirements, control the flammable vapors and other materials. If wiring and equipment is intrinsically safe, it can be used in any of OSHA's hazardous locations. One of the first online sellers of paint booths, we are recognized by Google Inc. (1,000,000 Leads Generated), and Internet Retailer (America's Top 500 Largest Retail Web Sites), we have a history as a successful online retailer. Our experts will build a system from the ground up to make what works best for your application needs, then install, maintain and provide replacement parts for the system as needed. Finally, if something isstill in question, rather than assuming that I know better, I check with facility personnel. That is why special color corrected light tubes are usually used in spay booth. The following items are prohibited within 20 feet of a spray area unless separated by a partition: In its spray finishing rules (29 CFR 1910.107), OSHA states that wiring and electrical equipment must conform to the requirements in 29 CFR 1910.107(c), the electrical requirements under Subpart S (29 CFR 1910.301 -, state that certain items in and around spraying areas must meet, be explosion-proof type approved for Class I, Group D locations, and. This is very efficient, especially when compared to conventional lights that convert 90% of energy to heat.

While these regulations are not used universally in the United States, dozens of state governments have adopted it for use in their jurisdiction. Every spray booth constructed in the U.S. that is used in a workplace environment is required to comply with OSHA regulations and standards, so it is important for spray booth owners and operators to understand that regulations are enforceable long after the booth is completed. Fortunately for auditors, this equipment must bear a label identifying it as suitable for the particular hazardous location. 4. OSHA defines the spraying area as any area where dangerous quantities of flammable vapors, mists, and the like result from spraying processes. It is a great guide to get you started, but because codes change, especially between states, its best to consult several resources. Proper lighting in the paint spray booth is essential because it help you achieve optimal paint finish at first attempt. The overall design of LED makes it easy to be installed even in corners for effective illumination. Equipment that is intrinsically safe was designed and constructed this way, and there will be documentation to support this. Signs prohibiting smoking, flames, and sparks should be displayed within 20 ft of the booth. When conducting spray finishing using flammable and/or combustible materials, many facilities use a paint booth or a ventilated spray area to limit employee exposure and prevent accumulation of explosive atmospheres. and the documentation must be available to those who are authorized to design, install, inspect, maintain, or operate electric equipment at the location (29 CFR 1910.307(b)). A spray booth is a power-ventilated structure that completely or partially encloses a spraying operation to control the flammable vapors and other materials. stream They offer an overview of pertinent safety information here. If your local codes require ETL certification, the easiest way to ensure compliance is to purchase an ETL-listed booth. It does not have more or less stringent requirements than NFPA-33 but some requirements are included in sections outside of the spray booth chapter. I have seen uncovered lamps, spark-producing grinders, and even welding units that had been moved into the 20-foot exclusion zone without being separated by a partition. On the other hand, the color temperature should range between 5500 and 6000K. Booth should be designed to sweep air currents toward the exhaust outlet. 29 CFR 1910.107(c) contains the general requirements for spray finishing operations, electrical issues and other sources of ignition. located inside of paint booths and spray areas. Also: there are lots of things you can try to DIY.

4 0 obj Figure 1 shows an example of such a label for a piece of equipment that is suitable for a Class I, Division 2 location. Markel does not guarantee that this information is or can be relied on for compliance with any law or regulation, assurance against preventable losses, or freedom from legal liability.

endobj

Beyond, approved for use in a hazardous location. If you are unsure if it will be required, it is best to purchase a booth that is already certified. Ideally paint spray booth lighting should be as close as possible as the natural light outside. The EPA has offices in each of the states and in addition to national regulations, states often have regulations related to VOC's as well. Clean any overspray from the exhaust fans. Portable electric lamps may be used inside of a spraying area during cleaning or repairs, but only if approved for Hazardous Class I locations.

endobj

Beyond, approved for use in a hazardous location. If you are unsure if it will be required, it is best to purchase a booth that is already certified. Ideally paint spray booth lighting should be as close as possible as the natural light outside. The EPA has offices in each of the states and in addition to national regulations, states often have regulations related to VOC's as well. Clean any overspray from the exhaust fans. Portable electric lamps may be used inside of a spraying area during cleaning or repairs, but only if approved for Hazardous Class I locations.  <>/ExtGState<>/Font<>/ProcSet[/PDF/Text/ImageB/ImageC/ImageI] >>/MediaBox[ 0 0 612 792] /Contents 4 0 R/Group<>/Tabs/S/StructParents 0>>

Although OSHA's electrical requirements within paint booths and spray areas can seem overwhelming, the following tips can help you successfully navigate the requirements: Curt Johnson, CPEA, is an STC Senior Program Director in Richmond, TX. The inside of a spray booth can be considered a spraying area if the ventilation fails or its efficiency has been limited, such as from. 3. Check out. Recent projects include developing the management system and its documentation for a major food producer; analyzing regulatory requirements for a large U.S. oil refiner and distributor; and assessing management systems conformance for an offshore fleet operation. LED light converts 90% of their energy to light.

<>/ExtGState<>/Font<>/ProcSet[/PDF/Text/ImageB/ImageC/ImageI] >>/MediaBox[ 0 0 612 792] /Contents 4 0 R/Group<>/Tabs/S/StructParents 0>>

Although OSHA's electrical requirements within paint booths and spray areas can seem overwhelming, the following tips can help you successfully navigate the requirements: Curt Johnson, CPEA, is an STC Senior Program Director in Richmond, TX. The inside of a spray booth can be considered a spraying area if the ventilation fails or its efficiency has been limited, such as from. 3. Check out. Recent projects include developing the management system and its documentation for a major food producer; analyzing regulatory requirements for a large U.S. oil refiner and distributor; and assessing management systems conformance for an offshore fleet operation. LED light converts 90% of their energy to light. Since spray booth operations generally present a higher risk of fire and hazardous exposure, owners are responsible for meeting several sets of minimum standards enforced by different agencies. Each agency has varying roles in relation to spray applications and safety. foot exclusion zone without being separated by a partition. Once your paint booth is compliant with all relevant codes and standards, preventative maintenance is the best thing you can do to keep it that way. 3 0 obj Fortunately for auditors, this equipment must bear a label identifying it as suitable for the particular hazardous location. LED works well under hot or cold temperature setting. Standard Tools and Equipment Co. was established in 1979 to service the auto body and collision repair industry. To avoid this, then you need to install an explosion proof lighting. The overall design of LED lights makes them ideal for paint spay booth. Be advised that flammable and combustible liquids have their own, storage, handling, and disposal requirements.

In addition, OSHA has requirements for the design of equipment and operations involved in spraying flammable or combustible materials. 4 0 obj Spray booths are not one of them. Consult with the right team of professionals to make sure your booth will be up to code. These include: skin irritation, fatigue, difficulty breathing, chest pain, nausea, rapid heartbeat, and blurry vision. <> You can also obtain certification for an existing booth by scheduling an official inspection and completing any required changes. This article attempts to organize the information about electrical requirements in a more user friendly manner.

They have complied with OSHA standards, Why you need to which LED lights in paint booth, 4. The reason why other forms of lighting such as incandescent lighting is not recommended for paint spray booth is because there glass is to light hence vulnerable to explosion. There are both local and national regulations that apply to the installation and operation of your spray booth. Ventilation should be kept on during and after all spraying operations for a sufficient time to dissipate vapors. The content of this document is made available on an as is basis, without warranty of any kind.

All of our paint booths comply with all OSHA and NFPA 33 guidelines and many can be ETL certified. In particular, 29 CFR 1910.107(c)(6) and (c)(8) state that certain items in and around spraying areas must meet the requirements forhazardous locations under Subpart S, as follows: The requirements for electrical items in hazardous locations (of all classes) are found in 29 CFR 1910.307. Each state has regulations and standards that cover worker safety. In my opinion, some of this confusion arises from the disorganization of OSHA's requirements. He has more than 30 years experience in the development and implementation of environmental, health and safety management systems. Paint booth compliance is about more than just following building codes; a compliant booth is safer to operate.

All of our paint booths comply with all OSHA and NFPA 33 guidelines and many can be ETL certified. In particular, 29 CFR 1910.107(c)(6) and (c)(8) state that certain items in and around spraying areas must meet the requirements forhazardous locations under Subpart S, as follows: The requirements for electrical items in hazardous locations (of all classes) are found in 29 CFR 1910.307. Each state has regulations and standards that cover worker safety. In my opinion, some of this confusion arises from the disorganization of OSHA's requirements. He has more than 30 years experience in the development and implementation of environmental, health and safety management systems. Paint booth compliance is about more than just following building codes; a compliant booth is safer to operate.  Local fire codes may be stricter than NFPA regulations. LED light does not get hot as it is usually the case with traditional lighting. Reviews

It is a great guide to get you started, but because codes change, especially between states, its best to consult several resources. (Source: is the last option allowed for electrical equipment and wiring. are found in 29 CFR 1910.307. For example, automobile undercoating spray operations in garages are exempted from many of the requirements when using certain materials that are less hazardous or solvents with a flash point exceeding 100F (thus 29 CFR 1910.107(c)(1) refers automobile undercoaters to 1910.107(k)). Proper light fixture must be considered when installing spray booth lighting. And what about after its built? This code is commonly used in areas of international trade zones. Inspect fire suppression equipment frequently. Maintain a clear space of at least 3 ft on all sides and above the spray booth. In reality, however, many standards apply and different localities have varying ordinances and permit requirements. The balance of this article discusses audit findings and, in some cases, what one would expect in the related action item. Before we get started, lets be clear: this list is not intended as a comprehensive resource. This results in many variations dependent on your location. In this paper we will cover some of the primary areas that each organization works relating to paint booths. Save my name, email, and website in this browser for the next time I comment. OSHA's General Industry standards (29 CFR 1910) regulate paint booths1 and spray areas under both the Ventilation requirements in Subpart G (29 CFR 1910.94) and the Spray Finishing Using Flammable and Combustible Liquids requirements in Subpart H ((29 CFR 1910.107). While I readily admit to not being trained as an electrician and only have a passing understanding of the National Electric Code, I can tell when lighting or wiring is not enclosed, and I know that power strips and most plug-in tools and equipment are not approved for use in hazardous locations. Paint booths might be heated, but the heating elements. If you want to get quality paint finish, then you need to ensure that that there is proper lighting. do not release enough energy to cause ignition. OSHA requirements, fire codes, and electrical/building codes are quite specific about electrical wiring and equipment located inside a paint booth or spraying area and in the downstream exhaust path. One main feature that makes LED light ideal for explosion proof application is their toughened glass. xOk@Q*hBSBBQk%V}o8;]&s\LMg~j0qw$1`juk|$9gdrJnzLVHX$qDQ@.bV That's why you often see skylights and clear panels lighted from outside the booth. These lightings have complied with OSHA standards meaning that their operating temperature is lower than the ignition temperature of the finishing material. not possess enough electrical energy for a spark to ignite flammable gas. outside of the work area and zone of separation. LED bulb use didoes that have incredible operational life. To prevent future problems, the employer must instill an understanding of requirements, using training and/or signs, and then verify compliance through regular inspection. 3 0 obj

Therefore a qualified employee (or a qualified person acting on behalf of the employer)may produce a description defining how the design meets the requirements of NFPA 70 and thusdemonstrate that the installation issafefor the hazardous location.

Local fire codes may be stricter than NFPA regulations. LED light does not get hot as it is usually the case with traditional lighting. Reviews

It is a great guide to get you started, but because codes change, especially between states, its best to consult several resources. (Source: is the last option allowed for electrical equipment and wiring. are found in 29 CFR 1910.307. For example, automobile undercoating spray operations in garages are exempted from many of the requirements when using certain materials that are less hazardous or solvents with a flash point exceeding 100F (thus 29 CFR 1910.107(c)(1) refers automobile undercoaters to 1910.107(k)). Proper light fixture must be considered when installing spray booth lighting. And what about after its built? This code is commonly used in areas of international trade zones. Inspect fire suppression equipment frequently. Maintain a clear space of at least 3 ft on all sides and above the spray booth. In reality, however, many standards apply and different localities have varying ordinances and permit requirements. The balance of this article discusses audit findings and, in some cases, what one would expect in the related action item. Before we get started, lets be clear: this list is not intended as a comprehensive resource. This results in many variations dependent on your location. In this paper we will cover some of the primary areas that each organization works relating to paint booths. Save my name, email, and website in this browser for the next time I comment. OSHA's General Industry standards (29 CFR 1910) regulate paint booths1 and spray areas under both the Ventilation requirements in Subpart G (29 CFR 1910.94) and the Spray Finishing Using Flammable and Combustible Liquids requirements in Subpart H ((29 CFR 1910.107). While I readily admit to not being trained as an electrician and only have a passing understanding of the National Electric Code, I can tell when lighting or wiring is not enclosed, and I know that power strips and most plug-in tools and equipment are not approved for use in hazardous locations. Paint booths might be heated, but the heating elements. If you want to get quality paint finish, then you need to ensure that that there is proper lighting. do not release enough energy to cause ignition. OSHA requirements, fire codes, and electrical/building codes are quite specific about electrical wiring and equipment located inside a paint booth or spraying area and in the downstream exhaust path. One main feature that makes LED light ideal for explosion proof application is their toughened glass. xOk@Q*hBSBBQk%V}o8;]&s\LMg~j0qw$1`juk|$9gdrJnzLVHX$qDQ@.bV That's why you often see skylights and clear panels lighted from outside the booth. These lightings have complied with OSHA standards meaning that their operating temperature is lower than the ignition temperature of the finishing material. not possess enough electrical energy for a spark to ignite flammable gas. outside of the work area and zone of separation. LED bulb use didoes that have incredible operational life. To prevent future problems, the employer must instill an understanding of requirements, using training and/or signs, and then verify compliance through regular inspection. 3 0 obj

Therefore a qualified employee (or a qualified person acting on behalf of the employer)may produce a description defining how the design meets the requirements of NFPA 70 and thusdemonstrate that the installation issafefor the hazardous location. The findings I've discussed above are relatively clear cut, and the actionsrequired to correct the problem and prevent its recurrence are also relatively straightforward. They are a critical aspect of safely applying coatings in your facility and installing your spray paint booth requires numerous parts and a lot of manpower. While not defined within the electrical sections of OSHA. The operating temperature of the lighting must be lower than the ignition temperature of the lighting finishing material. document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); This site uses Akismet to reduce spam. If proper lighting is not installed, then the light can trigger the gas to explode causing massive injuries or even death to people who are close around. They might even have a copy of a demonstration showing how their operation meets the requirements. Such installationsmust be documented, and the documentation must be available to those who are authorized to design, install, inspect, maintain, or operate electric equipment at the location (29 CFR 1910.307(b)). %PDF-1.5 When considering partitions, by the way, OSHA provided the following guidance in 1976: An adequate partition is one that would be vapor proof, and of such a height that the vapors and/or spray material could not go over the top. Spray booth light also need to be positioned correctly. Each state has regulations and standards that cover worker safety. 3042 Rotterdam, Netherlands; Van Noortwijcksingel. This provision (in 29 CFR 1910.307(c)(3)) allows the employer to demonstrate that the system as designed meets the needs and requirements for the location: Equipment that is safe for the location shall be of a type and design that the employer demonstrates will provide protection from the hazards arising from the combustibility and flammability of vapors, liquids, gases, dusts, or fibers involved. overview of pertinent safety information here, http://www.spraysystems.com/news/what-does-my-booth-need-to-be-code-compliant, https://globalfinishing.com/2011/06/22/paint-booth-code-compliance-what-you-need-to-know-and-why/, https://www.hppneumatics.com/minimum-requirements-paint-booth/, https://pittsburghsprayequip.com/blogs/pittsburgh-spray-equipment-company/paint-booth-code-compliance-safety-regulations, https://globalfinishing.com/2018/09/20/what-does-my-paint-booth-need-to-achieve-code-compliance, https://www.toolsusa.com/blog/spray-paint-booth-codes-and-regulations/. Why lighting is essential in paint spray booth? $.' Equipment that is specifically approved for locations containing both deposits of readily ignitable residue and explosive vapors. endobj Copyright 2022 Standard Tools and Equipment Co.. | Ecommerce Shopping Cart Software by Miva, Inc. Just how will your manufacturer make sure your booth is up to code? :R(:Mne{V&T/.vW4tiH,-|v;{+=YJmjC'V~[_(-aEr"I:~w49u_q"#i`O{Jw6WK5X["K/dqtuY1E'^ik+pHy_J/%)tnC!3wOiko>LeQ0KZR}jhcsyYQKN. While I readily admit to not being trained as an electrician and only have a passing understanding of the National Electric Code, I can tell when lighting or wiring is not enclosed, and, know that power strips and most plug-in tools and equipment are not approved for use in hazardous locations. Evaluating a paint booth requires complex engineering calculations and numerous regulations and codes. This article focuses on the design and operating requirements for electrical components in the Subpart H regulations and how they cross-reference with OSHA's Subpart S (Electrical)requirements. You obviously must first work with your local fire officials and meet the requirements that they have set for spray booth operations. Figure 1 shows an example of such a label for a piece of equipment that is suitable for a Class I, Division 2 location. Any open flames and equipment that can produce sparks (29 CFR 1910.107(c)(2)), and. Both the rating and operating temperature needs to be visible on the lighting source. This publication is not intended to be legal, underwriting, or any other type of professional advice. But, If appropriately designed, higher current and voltage equipment can be, , being explosion-proof, dust-tight, hermetically sealed, etc.) Another feature that makes LED light explosion proof is due to the fact that they have complied with OSHA standards. Works well under hot or cold temperatures. We will assist you in developing the appropriate amount of inventory you need to have on hand, when to order replenishment, and keep your operation running effectively. Codes are designed to ensure you operate your booth safely and correctly. safe for the hazardous (classified) location. For many operators, a professionally-engineered booth is the most effective and economical way to apply spray and finish compounds responsibly. This document cant be assumed to contain every acceptable safety and compliance procedures or that additional procedures might not be appropriate under the circumstances.

The many codes and regulations regulating your operation are in place to make your spray paint booth a safer one safer for you, safer for your employees and safer for your business. <> The last thing that any paint operator would want is being forced to add another layer of paint later because of poor lighting. JFIF ` ` C 2 0 obj Because the vapors from flammable and combustible liquids don't play well with electricity (think fires and explosions), OSHA has established electrical requirements in and around paint booths and spraying areas. Your insurance company will in all likelihood require stricter fire suppression requirements to: In a perfect world, achieving code compliance would be a one-size-fits-all activity. When you are purchasing a paint booth, make sure to choose one that meets federal standards and is ETL-certified (if your local codes require it). By understanding the related rules and codes of your paint booth you can better understand why they are required for spray operations as well as safety factors that you should consider with the use of your paint booth. Unprotected combustible materials should be at least 18 inches away from exhaust ducts. That's why you often see skylights and clear panels light, outside the booth. Persons requiring advice should consult an independent adviser. Make sure your booth is up to code and properly maintained before inspection with these general guidelines and spray booth safety tips. Additionally, some state government agencies require full compliance of the International Fire Code, a code that enforces regulations on fire safety and prevention in the workplace. Write a review, Reduce property damage exposed to potential fire damage, Reduce exposure to business income loss were a fire or explosion to occur, Minimize the chances of damage to high value vehicles were an explosion to occur, Reduce the chances of damage to neighbors property due to an explosion or rapidly spreading fire, Reduce the chances of bodily injury to employees or the public, The four most common regulatory bodies related to paint booths in the United States include the National Fire Prevention Association (, , Occupational Safety and Health Administration (. 1OSHA uses the terms "spray booth" and "spray area" to encompass spray application of any flammable or combustible material. <> Compliance is one of the most complex issues that you may deal with as a paint booth owner. If you are planning to install lighting in paint spray booth, then you wont go wrong if you choose LED lights. normally installed to be intrinsically safe. By understanding the codes that are applicable to your operation, your booth can be built and assembled in accordance with multiple national and international standards. explosive vapors and combustible residues-no one, electrical equipment can be placed in a spray area where combustible deposits may accumulate except, OSHA prohibits space-heating appliances, steampipes, and other hot surfaces from being located in a spraying area (29 CFR 1910.107(c)(3)), be used inside a spraying area during spraying activities (29 CFR 1910.107(c)(8)). If wiring and equipment is intrinsically safe, it can be used in any of OSHA's hazardous locations. All metal elements of spray booths, exhaust ducts, and piping must be electrically grounded in a permanent manner. build-up on filters. There may be situations where you already have a spray paint booth, purchased one listed as meeting Underwriters Laboratories (UL) standards, or even purchased an existing booth from someone else that is disassembled and re-assembled which does not have a fire suppression system. The strong and thick glass that LED lights contains means that any spark produces will be more tightly contained. It is in your best interest to work with someone knowledgeable in code compliance to identify which codes are applicable so that you can bring your spray paint booth into compliance and in turn minimize those associated fire risks. Keep your spray booth clean and change filters regularly. They also have the best color lighting for paint booth. In most cases however, compliance with NFPA 33 is acceptable to meet OSHA's requirements. The inside of a spray booth can be considered a spraying area if the ventilation fails or its efficiency has been limited, such as from paint build-up on filters.

When preparing to build a spray booth, make sure your manufacturer will be able to meet the minimum requirements for paint booths with the following groups: Youll also want to make sure your booth will be up to code with the Occupational Safety and Health Administration (OSHA), the National Fire Protection Association (NFPA) and the Environmental Protection Agency (EPA). Markel does not guarantee any particular outcome and makes no commitment to update any information herein, or remove any items that are no longer accurate or complete. LED lights can be switched on and off many times but that will not affect its light emission or durability. To prevent future problems, the employer must, www.cisco.com/en/US/docs/wireless/access_point/1552hz/installation/guide/1552hz_ch2.html, http://www.transcat.com/technical-reference/PDFs/Application%20Notes/cordex-is-explosion-proof.pdf, Wiring in rigid conduit or boxes or fittings containing no taps, splices, or terminal connections, or. A few small scale spray paint operations may not meet NFPA 33 requirements. There are many things you can try to do-it-yourself, spray paint booths are not one of them. Because we have so many filters in stock, we guarantee a quick turnaround for filter replenishment. Curt Johnson, CPEA, STC Senior Program Director, Richmond, TX. The section goes on to explain what is required to satisfy each of these three options. % Sign up to our newsletter & Receive Savings In Your Inbox. % Youll also want to make sure your booth will be up to code with the Occupational Safety and Health Administration (OSHA), the National Fire Protection Association (NFPA) and the, Not sure what type of booth is best for you? If the employer has substituted a different piece of equipment or an item is not contained in the demonstration (probably because it was movedinto the area later), there's a problem. The quality of lighting that you install in a paint spray booth will determine the overall finish quality. 2 0 obj To learn more about paint booth compliance, contact our experienced team. Many states adopt the federal requirements. Common sources of ignition are light fixtures, switches and certain types of fans. Although auditors should have a thorough understanding of these electrical requirements, OSHA's requirements for electrical components leave many auditors and facility safety managersscratching their heads. Finally, if something, an item is not contained in the demonstration (probably because it was, The findings I've discussed above are relatively clear cut, to correct the problem and prevent its recurrence. If your booth isnt code compliant, the best thing to do is remedy the situation right away by scheduling an inspection and completing any assigned action items. These primary guidelines will also help you maintain your booth after its built: Be advised that flammable and combustible liquids have their own storage, handling, and disposal requirements. Another regulation that manufacturer needs to meet include installing lighting that comply with the national electrical code standards for electrical device. Required fields are marked *. Almost every business is subject to safety and environmental regulations and codes on both a local and national level. LED have a lifespan of 100,000 (11 years) of continuous operation and up to 20 years is not used continuously. 1. Spray booths should be constructed of steel, concrete, or masonry, and securely and rigidly supported. , I use a combination of common sense and diligence.

However, this can be a costly certification process. Equipment that is intrinsically safe was designed and constructed this way, and there will be documentation to support this.

endobj This Electrical Testing Laboratories mark indicates that the booths components meet certain NFPA safety requirements. This article focuses on the design and operating requirements, control the flammable vapors and other materials. If wiring and equipment is intrinsically safe, it can be used in any of OSHA's hazardous locations. One of the first online sellers of paint booths, we are recognized by Google Inc. (1,000,000 Leads Generated), and Internet Retailer (America's Top 500 Largest Retail Web Sites), we have a history as a successful online retailer. Our experts will build a system from the ground up to make what works best for your application needs, then install, maintain and provide replacement parts for the system as needed. Finally, if something isstill in question, rather than assuming that I know better, I check with facility personnel. That is why special color corrected light tubes are usually used in spay booth. The following items are prohibited within 20 feet of a spray area unless separated by a partition: In its spray finishing rules (29 CFR 1910.107), OSHA states that wiring and electrical equipment must conform to the requirements in 29 CFR 1910.107(c), the electrical requirements under Subpart S (29 CFR 1910.301 -, state that certain items in and around spraying areas must meet, be explosion-proof type approved for Class I, Group D locations, and. This is very efficient, especially when compared to conventional lights that convert 90% of energy to heat.

While these regulations are not used universally in the United States, dozens of state governments have adopted it for use in their jurisdiction. Every spray booth constructed in the U.S. that is used in a workplace environment is required to comply with OSHA regulations and standards, so it is important for spray booth owners and operators to understand that regulations are enforceable long after the booth is completed. Fortunately for auditors, this equipment must bear a label identifying it as suitable for the particular hazardous location. 4. OSHA defines the spraying area as any area where dangerous quantities of flammable vapors, mists, and the like result from spraying processes. It is a great guide to get you started, but because codes change, especially between states, its best to consult several resources. Proper lighting in the paint spray booth is essential because it help you achieve optimal paint finish at first attempt. The overall design of LED makes it easy to be installed even in corners for effective illumination. Equipment that is intrinsically safe was designed and constructed this way, and there will be documentation to support this. Signs prohibiting smoking, flames, and sparks should be displayed within 20 ft of the booth. When conducting spray finishing using flammable and/or combustible materials, many facilities use a paint booth or a ventilated spray area to limit employee exposure and prevent accumulation of explosive atmospheres. and the documentation must be available to those who are authorized to design, install, inspect, maintain, or operate electric equipment at the location (29 CFR 1910.307(b)). A spray booth is a power-ventilated structure that completely or partially encloses a spraying operation to control the flammable vapors and other materials. stream They offer an overview of pertinent safety information here. If your local codes require ETL certification, the easiest way to ensure compliance is to purchase an ETL-listed booth. It does not have more or less stringent requirements than NFPA-33 but some requirements are included in sections outside of the spray booth chapter. I have seen uncovered lamps, spark-producing grinders, and even welding units that had been moved into the 20-foot exclusion zone without being separated by a partition. On the other hand, the color temperature should range between 5500 and 6000K. Booth should be designed to sweep air currents toward the exhaust outlet. 29 CFR 1910.107(c) contains the general requirements for spray finishing operations, electrical issues and other sources of ignition. located inside of paint booths and spray areas. Also: there are lots of things you can try to DIY.

4 0 obj Figure 1 shows an example of such a label for a piece of equipment that is suitable for a Class I, Division 2 location. Markel does not guarantee that this information is or can be relied on for compliance with any law or regulation, assurance against preventable losses, or freedom from legal liability.