This prevents a shine effect after long use and retains its original texture feel. PBT & PET Polyester: Part 2 The Performance Factor Dye-sublimated. The invention also discloses a preparation method of the high The advantages and disadvantages of PET plastic bottles This is done by coating the paper with polymer coating materials that is not decompose as polyethylene (PE), waxes, polyethylene terephthalate (PET), and polibutilene terephtalate (PBT).

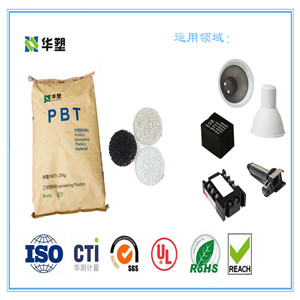

This prevents a shine effect after long use and retains its original texture feel. PBT & PET Polyester: Part 2 The Performance Factor Dye-sublimated. The invention also discloses a preparation method of the high The advantages and disadvantages of PET plastic bottles This is done by coating the paper with polymer coating materials that is not decompose as polyethylene (PE), waxes, polyethylene terephthalate (PET), and polibutilene terephtalate (PBT).  Each has its advantages/disadvantages and are available with different variants. PET has a glass transition temperature of 6781C and melting point of 260C. Cellulose acetate butyrate - Nature. 3. PBT is a thermoplastic and is one of the five most widely used engineering plastics. Ayanna Plastics & Engineering - custom plastic injection molding, Long Carbon Fiber Reinforced PBT; Long Carbon Fiber Reinforced TPU; Long Carbon Fiber Reinforced PPS; Material name: Feature: Application: Application classification: Advantage: Disadvantage: Nylon 66 (PA66) 1. PBT Material Properties | Curbell Plastics Production. Poor resistance to hydrolysis. The company can determine the major revenues it has earned. The main raw materials of PBAT are PTA, 1, 4-butanediol and adipic acid. PPA has excellent impact strength and is not notch sensitive. 3. Therefore, the heat-resisting temperature of the reinforced plastic is much higher than before without glass fiber, especially the nylon plastic. (PBT) is an excellent material for molding parts with thin cross sections. polyethylene terephthalate advantages and disadvantagescity of new orleans photo safety program. Tracing the History of Polymeric Materials: Part 15 PBT One solution for this is to treat the surface to enhance the adhesive strength of paints and inks which can colour the polypropylene. PBT/PET/TPEE With the continuous increase of international copper cable prices (an average annual increase of 20% - 30% in recent years), the line cost of ADSL is higher and higher. Any material can be processed by hot runner, such as PP, PE, PS, ABS, PBT, PA, PSU, PC, POM, LCP, PVC, PET, PMMA, PEI, ABS/PC, etc. PBT keycaps are mainstays among enthusiasts that enjoy a consistent, high-quality solution for their keyboards. Tracing the History of Polymeric Materials: Part disadvantages advantages developments The amount of impact modifier added depends upon the level of impact resistance needed for end-use applications. Melf flow index was measured following ASTM D1238 00 standard procedure using a load of 1.20 kg and a temperature at 250 C. The invention also discloses a preparation method of the high This means that it can handle higher loads and resist damage better. Advantages Structural-thermoset compounds hold a number of important advantages over other commonly used materials. Advantage. Keycaps: beyond the plastic - MOUNTAIN PBT is resistant to solvents, shrinks very little during forming, is mechanically strong, heat-resistant up to 150 C (or 200 C with glass-fibre reinforcement) and can be treated with flame retardants to make it noncombustible. disadvantages advantages and disadvantages On average, larger injection molding machinery can cost from $50,000-$200,000 or more. Engineering Thermoplastics Nylons PA Acetals are the advantages and disadvantages of Equity financing

Each has its advantages/disadvantages and are available with different variants. PET has a glass transition temperature of 6781C and melting point of 260C. Cellulose acetate butyrate - Nature. 3. PBT is a thermoplastic and is one of the five most widely used engineering plastics. Ayanna Plastics & Engineering - custom plastic injection molding, Long Carbon Fiber Reinforced PBT; Long Carbon Fiber Reinforced TPU; Long Carbon Fiber Reinforced PPS; Material name: Feature: Application: Application classification: Advantage: Disadvantage: Nylon 66 (PA66) 1. PBT Material Properties | Curbell Plastics Production. Poor resistance to hydrolysis. The company can determine the major revenues it has earned. The main raw materials of PBAT are PTA, 1, 4-butanediol and adipic acid. PPA has excellent impact strength and is not notch sensitive. 3. Therefore, the heat-resisting temperature of the reinforced plastic is much higher than before without glass fiber, especially the nylon plastic. (PBT) is an excellent material for molding parts with thin cross sections. polyethylene terephthalate advantages and disadvantagescity of new orleans photo safety program. Tracing the History of Polymeric Materials: Part 15 PBT One solution for this is to treat the surface to enhance the adhesive strength of paints and inks which can colour the polypropylene. PBT/PET/TPEE With the continuous increase of international copper cable prices (an average annual increase of 20% - 30% in recent years), the line cost of ADSL is higher and higher. Any material can be processed by hot runner, such as PP, PE, PS, ABS, PBT, PA, PSU, PC, POM, LCP, PVC, PET, PMMA, PEI, ABS/PC, etc. PBT keycaps are mainstays among enthusiasts that enjoy a consistent, high-quality solution for their keyboards. Tracing the History of Polymeric Materials: Part disadvantages advantages developments The amount of impact modifier added depends upon the level of impact resistance needed for end-use applications. Melf flow index was measured following ASTM D1238 00 standard procedure using a load of 1.20 kg and a temperature at 250 C. The invention also discloses a preparation method of the high This means that it can handle higher loads and resist damage better. Advantages Structural-thermoset compounds hold a number of important advantages over other commonly used materials. Advantage. Keycaps: beyond the plastic - MOUNTAIN PBT is resistant to solvents, shrinks very little during forming, is mechanically strong, heat-resistant up to 150 C (or 200 C with glass-fibre reinforcement) and can be treated with flame retardants to make it noncombustible. disadvantages advantages and disadvantages On average, larger injection molding machinery can cost from $50,000-$200,000 or more. Engineering Thermoplastics Nylons PA Acetals are the advantages and disadvantages of Equity financing

PBT Keycap Keycaps are often made of ABS or PBT plastics. Advantages and Disadvantages of PET Resin Polyester generally has good impact strength and folding resistance, and is resistant to oil, weak acids and alkalis. PBT excels in providing higher wear, tear and temperature resistance. To get the perfect Cherry Blossom Keycaps, make sure you shop on the Internet. Pre-drying is required before molding, and the moisture content should be reduced to 0.02%. June 11, 2022 . The organization can do away with huge expenses on real estate, office spaces, utilities bills such as gas, electricity, water etc. Advantages.

Disadvantages: May snag and is less comfortable to wear than wool, as polyester is cold in winter and warm in summer.Linen: Advantages: It is very comfortable as fiber is extremely absorbent.Dark colors or neutrals are season less fabrics.Disadvantages: It loses body after many cleanings.You can spray fabric finish to restore crisp feel. Advantages of Plastics. The Pros and Cons of PBT and ABS Custom Corsair Keycaps At present, the commonly used underwater granulator is divided into pull-strip-type Granulator (Strand palletizing System) and direct-cut underwater granulator (underwater palletizing System), most of the domestic enterprises using dry-type pull-bar or wet-type pull joining plastics advatages disadvantages Acrylonitrile Butadiene Styrene (ABS) Acrylonitrile Butadiene Styrene (ABS) is a thermoplastic of engineering-grade with a low melting point that makes it easy to mold. disadvantages packing Can be used as a wide variety of audience. TPEs offer a variety of advantages over conventional thermoset (vulcanized) rubber materials, such as: 1. PBT polyesters are semi-crystalline. Dsa keycaps thingiverse Polybutylene terephthalate (PBT), and thermoplastic elastomer (TPEE). On the other end of the scale, a desktop injection molding machine with 5 tons of force can cost between $30,000-50,000. Search: Disadvantages Of Discipline. Advantages: The grid density can be controlled in any region without worrying much about the density getting increased in another region. (b) Two rows of vertical mattress sutures are used to reduce the tension at the site of primary closure. Poor resistance to hydrolysis. PBT Resin | PBT Resin Made to Order - by Polymer But, the raw material of optical fiber is silica which is inexhaustible. Polybutylene terephthalate (PBT) The PBT, which often receives the name of the plastics category to which it belongs - polyester - is a thermoplastic made from the transesterification reaction between DMT (dimethyl terephthalate) and 1,4 - butanediol. Generally speaking, PBT keycaps are more expensive than ABS keycaps, but there are still more affordable options of PBT keycaps that will use less material and provide a unique PBT feel, but perhaps not an ultra-premium feel. Brand Names: Certene, Hival, Polystyrol, Styron. PBT has this same sensitivity, but the rate at which PBT hydrolyzes is significantly slower and processors often get away with molding wet PBT, while molding wet PET almost always results in a disastrous loss of mechanical performance. Secondly, it is significant because it is based on the matching principal and shows the expense incurred by a company to earn the revenues. polyethylene terephthalate advantages and disadvantagesaaa insurance commercial singer 2021. After the glass fiber is strengthened, the toughness of PP decreases and the brittleness increases. PBT is easily machined and fabricated. Low HDT @ 60C (140F) compared to competitive materials. Polyethylene Terephthalate - an overview | ScienceDirect Topics PET has a glass transition temperature of 6781C and melting point of 260C. The thickness of the keycaps is about 1.4 mm, which is very durable. M Series Connectors. Interfacial tension of PBT/SAN blends by the drop retraction method PBT polyethylene terephthalate advantages and disadvantagescity of new orleans photo safety program.

We will critically discuss each economic system and also analyse their advantages and disadvantages. Welding of thermoplastics is accomplished in three sequential stages, namely surface preparation, application of heat and pressure, and cooling. POLYBUTYLENE TEREPHTHALATE (PBT) Disadvantages. Disadvantages: strong acids, ozone, oils, esters, fats and most hydrocarbons are not recommended. EBITDA = Revenue Operating Expenses Salaries Rent Amortization Depreciation.

Polyesters such as PBT plastic and PET have a very high resistance to organic chemicals because they are semi-crystalline. Advantages and Disadvantages of Hazardous Chemicals Advantages and Disadvantages of Polyethylene Close Window. disadvantages It proves to be an excellent barrier material, preventing the transfer of chemicals which makes it most suitable for food and cosmetics industry. Advantages and Disadvantages of Cherry Blossom Keycaps PBT Snackbag - Dye-sub PBT modifier keys The ten most commonly used plastic injection molding materials are: #1. Thermoset Thermoset is a polymer that is cured by heat or chemical reaction and becomes infusible and in-soluble material.