TECHNICAL SUPPORT CALL916-992-6833, Copyright 2021 Pro Powder And Abrasive Supply | All Rights Reserved | Designed by, K-DEER ALUMINUM OXIDE 100 GRIT (BROWN FUSED ALUMINA) 48 LBS. Ready to begin? | The table below compares the hardness of BARTONs garnet to the hardness of typical abrasives used for surface preparation based on the Knoop Hardness Number. Over the last several years, it has also gained popularity for other abrasive blasting operations both indoor and outdoor blasting. Sometimes, it's best to consult a garnet expert in your planning stage of project to obtain the rightgarnet blasting mediafor your desired profile. This is safer for the worker both in breathing and visibility and can be essential for work site sandblasting where dust reduction is key. There are other ways to sandblast, including wheel blasting (which uses a spinning wheel instead of high-pressure air or liquid), dry ice blasting, bristle blasting (using a rotary steel wire bristle) and vacuum blasting, a method very useful to prevent dust spread. Wearing personal protection equipment is necessary, as well as avoiding eye contact. | Country Search Hence, the ability to do the job without undue damage to the substrate is invaluable.

Newsletter Subscription | Privacy Policy | Cookie Policy SALES CALL916-992-0968

ALLTEKGlobally sourced alluvial garnet processed to BARTONs high quality standards offering excellent performance and surface quality. - User Information Legal Enquiry Guide, 1999-2022 Alibaba.com. Its also ideal for finishing surfaces thanks to particle size precision and the lack of reactivity of garnet.

Range 0.0025 in to 0.0059 in, US Sieve 100, Standards OSHA. They also can sweep out rust within tight crevices.  Typically produces a 2.54.0 mil profile on steel. Its also essential and may be required by law when working around bodies of water or where contamination is a serious concern. If you need a Abrasive Roll, 1-1/2"Wx150ft. Its also far faster, thanks to the extreme sharpness of the surface edges of crushed garnet, saving labour costs.

Typically produces a 2.54.0 mil profile on steel. Its also essential and may be required by law when working around bodies of water or where contamination is a serious concern. If you need a Abrasive Roll, 1-1/2"Wx150ft. Its also far faster, thanks to the extreme sharpness of the surface edges of crushed garnet, saving labour costs.

| Showroom  From coarse through fine, BARTON offers garnet abrasives for a wide range of blasting applications.

From coarse through fine, BARTON offers garnet abrasives for a wide range of blasting applications.

If you havent got your listing sorted, now is the time to get your details listed. RFQ! It was used at the Eiffel Tower in Paris to remove a layer of wax from the granite base. Its become the preferred choice for fiberglass surfaces and aluminium structures as well. Dia and 9" x 11" Pro Grade Precision No-Slip Grip Sanding Sheet 220-Grit 3-Pk when you shop with us. It does not need special attention while handled. Glass beads can usually be recycled for reuse. All treatments applied to the victim must take into account the symptoms showed by that victim. However, garnet performance is determined by the virtue of energy produced by velocity. Plus, garnet can save significant money thanks to its ability to be reused considerably more than most other grit.

ESCA Warehouse Locations

Weve got millions of products including Refill Roll, 30 ft. L, Fine, Gold, 120 Grit and Sandpaper Sheet, Coarse, 40 Grit, Blue. Its very dense and can get reused up to 6x depending on a few factors. 20112022 Zoro Tools, Inc. All rights reserved

Do Not Sell My Personal Information, 20112022 Zoro Tools, Inc. All rights reserved, View More Products Related To 100 Grit Garnet Sand. The scouring effect of smaller grains can serve to clean away contamination from surface undulations.

Use a soft soap and clean water. We strongly recommend testing and sampling when approaching a sensitive or historical project. Furthermore, as garnet is an abrasive that generates minimal levels of dust, it facilitates efficient surface preparation without undue contamination of surrounding areas. Offer subject to certain terms and conditions. The grains are especially uniform compared to other grit and are almost entirely free from embedment, allowing reuse of media and a perfect surface for coating. Most importantly, determine the physical nature of the required finish (i.e. For further details, please contact us. Privacy Policy Micron Range 125 to 250, 55 lb, Box, Nominal Dia. In case of inhalation, the affected person must be taken out, to fresh air, and kept in a comfortable position so he/she can breathe properly. Oxide Very Fine Sanding Hand Pad you can find them right here. Find Hook-and-Loop Paper Disc, Gold, PK50 and Hook-and-Loop Sanding Disc, 220 Grit, PK50 when you shop our huge assortment. In our opinion, this Garnet blast media offers advantages for indoor blasting operations where reclamation is possible.

This abrasive material is successfully used on stainless steel, carbon steel, aluminium surfaces because it does not have any ferrous component, and thus, it does not impregnate the blasted surfaces. Good sand blasting grit suppliers will offer a range of sizes for various uses. Philadelphia, PA Environmentally safe and cost-effective method for metal surface cleaning and finishing. 30/60 CG Used to remove heavier coatings (up to 40 mils) and rust while controlling profile. Alipay Any corroded areas also require blast cleaning to a specified standard.

We are happy to have them as our supplier for blasting agents and equipment. A trustworthy brand, a professional team, a flawless service!

In addition to higher blasting rates, finer garnet grains produce a more uniform surface profile, cleaner finish and higher peak density.

This quality is reflected in an above-average service life, a very high productivity and value retention. Since it occurs naturally and is non-toxic, its much better for the environment than many other choices. Count on great prices, fast shipping and friendly service every time you order a 100 grit garnet sand from Zoro. Often, using a coarser abrasive can result in over-blasting that can produce an unacceptable surface finish. Its very dense and can get reused up to 6x depending on a few factors. Red Garnet is widely used in the Shipbuilding Industry. SACRAMENTO, CA 95838

To achieve a quality and uniform finish, it is essential to use a finer grade garnet to ensure the specified finish is obtained. Choosing the right abrasive is as critical as using the right pressures and blast methods. - Garnet is a genuine ripper and is overtaking other media as one of the most sought-after grits from sand blasting grit suppliers. Its formed when rock that contains a lot of aluminium is put under extreme pressures found deep underground.

Today we supply clients who use it in various ways, including their blast rooms, blast cabinets, vapor blasters, and dry blast machines. Alibaba.com Site: International - Espaol - Portugus - Deutsch - Franais - Italiano - - P - - - - - Trk - Nederlands - ting Vit - Indonesian - , AliExpress The shape of the grain its somewhat rounded enables this media to also be used on very delicate substrates, including wood and certain kinds of stone and masonry. We carry one in particular that costs 45% less: Powered Air Purifying Respirators (PAPRs), Free Project Support: Consumption and production rates, equipment and application recommendations, Shelf Life: Unlimited when stored indoors, Can perform vapor / dustless or dry blasting, New and Structural steel prep; mill scale removal, Oil & Gas Terminals, Petroleum refining, Pipelines, Hard Stone building facades, masonry, and brick restoration (testing required! Need rush service, lift gate, call ahead, or appt? Subscribe to the GMA blog to get the latest about garnet technologies and news from around the world. Check whether you are using the correct garnet grain size to achieve your desired surface profile.

80 HPA Used on steel, aluminum and other sensitive substrates. Finer garnet grades can enable more controlled blasting, more efficient blasting performance and cleaner surface profiles up to 75 microns. One of the most popular choices, garnet is an ideal choice for the widest range of applications and is technically considered a semi-precious stone when in gem form. Our garnet abrasives are ideal for use on steel, stainless steel, aluminum and other substrates. This item can be successfully used both for wet and for dry blasting. Terms & Conditions

Choosing the right abrasive can reduce downtime, minimize disruption, eliminate toxic heavy metals and cut costs.

AGSCO offers glass beads, used for precise metal finishing of parts.

Our garnet abrasives are available in a variety of grades to match your application needs and work cost effectively. We have years of experience in this field and would love the opportunity to discuss your project in more detail, so please contact us with any and all questions. When blasting, larger garnet grains facilitate deeper indentations than finer garnet grains but produce fewer impacts across any given area. | To understand how to choose the best sand blasting grit suppliers, youll want to understand how to choose the right grit for the job. If he/she has difficulties breathing, oxygen can be administered. Why Garnet Blast Media? This can result in increasing blasting rates by more than 10% and reducing the volume of abrasive used by up to 10%, resulting in shorter project times and lower cost. Many blasting and coating specialists default to using a 30/60mesh garnet abrasiveor a coarser garnet for surface cleaning and preparation. Traditionally, Garnet blast media has been seen as the industry standard for use in Water Jetting and UHP equipment. Being washed six times, and using approximately 580 cubic meters of water, this abrasive material has. Want to increase your blasting efficiency?

Garnet is ideally suited to recycling when used in blast-room settings, typically providing three to five turns, making it one of the most economical mineral abrasives on the market. Range 0.0049 in to 0.0098 in, US Sieve 100, Blast Media, Garnet, Media Grit 80, Nominal Dia. Use professional vacuum cleaners to clean the area. Terms of Use Reusing Garnet in these situations can be difficult if not impossible, and price-wise its not as economical as other less dense abrasives that offer the same performance characteristics. ADIRONDACKThe most refined hard rock garnet abrasive in the world delivers faster cleaning and impeccable surface quality. Romania, GritSablare All rights reserved.

Tmall Taobao World To request other media supplies with AMS, click here. Blasting Materials distributed by GritSablare are characterized by outstanding quality. You wont overpay for Paper Disc Roll, 220 Grit, 6 in. RFQ! Blasting with a finer grade garnet is beneficial when you have low-build coatings or heavily pitted surfaces. BARTON garnet grains scour deep into cavities and pitted areas down to bare metal, thoroughly removing all rust, soluble salts and other contaminants. Its a less aggressive media so it isnt great for heavy stripping, but it leaves a smooth, satin matte finish and provides less stress to the surface being blasted.

Its used extensively by the National Park Service at Gettysburg for cleaning and restoring many of the monuments and statues found there.

We offer comprehensive blasting waste recovery services for neutralization. According to major sand blasting grit suppliers, the most-used abrasives include: Specialty media can use a wide range of unusual material, such as corn cob and walnut shells, to achieve unusual patterns and results. Grand Rapids, MI Call Keith at 314-241-5333 or email keith@tcrcoatings.com.

Privacy Policy EFFECTIVELY REPLACES STAUROLITE, OFFERING SIGNIFICANT REDUCTIONS IN MATERIAL CONSUMPTION, IMPROVEMENTS IN PRODUCTIVITY, AND REDUCTIONS IN NUISANCE DUST, POWDER COATERS VALUE THE HIGH QUALITY SURFACE FINISH AND UNIFORM PROFILE CREATED BY GARNET. Standard paint removal (including graffiti) from brick, steel and concrete.

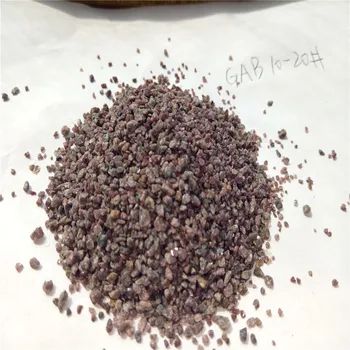

Micron Range 150 to 297, 55 lb, Box, Nominal Dia. Red Garnet is widely used in blasting chambers, when a non-ferrous abrasive material is needed, that would not interfere with the blasted surfaces. For example, when surface profiles above 75 microns are required, a relatively coarse garnet may be appropriate.

CAS number 1302-62-1, almandine and pyrope garnet.

The relatively large sized particles are used for general repairs and maintenance blasting operations, for removing old layers of paint, rust and other residue accumulations. Range 0.0165 in to 0.0278 in, US Sieve 36, Sandpaper Sheet, Length 11 in, Width 9 in, Grade Medium, 100 Grit, Abrasive Material Aluminum Oxide, Backing Material Paper, Backing Weight B, Color Tan, Package Quantity 20, Sanding Sheet, Length 4 in, Width 3 in, Grade Fine, 100 Grit, Abrasive Material Aluminum Oxide, Backing Material Paper, Backing Weight C, Color Gold, Series 236U, Package Quantity 50, Sandpaper Sheet, Length 11 in, Width 9 in, Grade Medium, 100 Grit, Abrasive Material Emery, Backing Material Cloth, Backing Weight J, Color Black, Series JC0250, Package Quantity 50, Sandpaper Sheet, Length 11 in, Width 9 in, Grade Fine, 100 Grit, Abrasive Material Aluminum Oxide, Backing Material Paper, Backing Weight B , Color Tan, Package Quantity 3, Blast Media, Garnet, Media Grit 80, Nominal Dia. Typically produces a 2.02.8 mil profile on steel. Its blasting speed and its extremely sharp edges are very important factors for an extremely efficient blasting process, executed with a low material consumption.

Red Garnet is a safe, ecologic and stable material. BARTONs garnet blasting abrasives offer you choice and flexibility for meeting specific application, performance and budgetary needs. It can be used for any job that sand or aluminium oxide can, with the added advantages listed above. Request your quote! Plastic urea abrasive is ideal for no-etch stripping.

At the Eiffel Tower, they dry blasted while using only simple containment measures and did not have to close down any of the sidewalks or other pedestrian routes. Logistics: We can deliver to virtually any location, including construction sites, residential addresses, military complexes, nearby terminals. Its brought to the surface by either tectonic or volcanic action and usually extracted by grit manufacturers from andradite and almandite deposits. Here's what to know. Woud you like to Continue on this page or Submit a quote? Please avoid dust. BARTON garnet is a 100% natural, nonferrous inert mineral with <0.1% respirable crystalline silica and no heavy metals. The multiple water washing operations it goes through, make this material very efficient in not raising semnificative dust during the blasting process, thus improving working conditions in close spaces, in tanks, etc. The use of a finer grain garnet gives the blaster greater control and helps wear away unwanted decoration without ripping into the surface. Therefore, using a finer garnet grade can prevent premature coating failure due to substandard cleanliness. If your company performs abrasive blasting as a significant portion of your operations, you need to purchase your abrasives in bulk from top sand blasting grit suppliers to reduce the price per pound. 36 CG Construction-grade cleaning power where removal speed is a priority. Intellectual Property Protection Once that happens, there is no going back. The blaster directory gives you the ability to advertise your services and products as well as display pictures of your capabilities and previous work achievements. Each has its advantages and disadvantages. GritSablare, a reliable and fast partner, always involved to learn and find solutions that fits customers' needs.

Stainless steel blasting: food tanks, stainless steel tubs, etc. When you remove thick, soft coatings, the surface may absorb the energy before the garnet grains achieve full impact potential.

20/40 grit garnet and 30/60 grit garnet are best suited for: 80 grit garnet and 120 grit garnet are ideal for: For more information on grit sizes, click here.

One of the most important decisions is the media used for stripping. -

1688.com Optimal blasting performance is achieved by matching the correct garnet grain size for the specific job with clean, dry compressed air at the appropriate pressure in conjunction with controlled abrasive flow rates. Greensboro, NC. Take advantage of our expertise in Blast Operation development for both Regulatory Compliance and Operational efficiencies. All rights reserved.

Talk to a GMA expertabout the abrasive that's right for your application. The crystalline structure means that, for breathing purposes, its considered silica-free, so silicosis isnt a hazard when using it. All it needs is a good air ventilation in the storage space. Designed by WebStrategy.

Coated Abrasives Garnet Paper Sheets , 9" Sheet Width, 11" Sheet Length, C-Weight, Medium/Coarse Grit 100, Garnet Abrasive, 55lb, No.16Grit, 12-20Mesh, Blast Media, Garnet, Media Grit 100, Nominal Dia.

At a low pressure, the grains bounce off the surface rather than cutting into it. Intact paintwork needs to be brush blasted to remove loose paint, contamination and produce a surface profile for subsequent recoating.

In this case, a medical intervention is also necessary.

Smaller garnet grains will facilitate controlled surface preparation, localized repairs and create the desired feathering effect onto the intact resin. B2-20120091-4. The process varies considerably in methods, materials and pressures; indeed, ideal results require a thorough understanding of the physics involved and a skilled operator.

AGSCO offers glass beads combined with graded aluminum oxide to form a group of specially blended mixes used for cleaning and texturing. Get the guide to explore abrasives and the alternative that's helping industrial teams get the job done right. Specialized finishes on applications like graffiti removal, fiberglass and flash blasting are possible by the combination of finer grains and variable air pressure. Garnet is not reactive with water and is considered ideal for entrained water jet cutting. Micron Range 63 to 150, 50 lb, Bag, Nominal Dia. The unique physical nature of garnet being sharp, hard and tough allows usage at lower air pressures, avoiding over-blasting or unnecessary damage to the substrate. BARTON garnetis two to four times harder and up to two times heavier than ordinary abrasives like crushed glass, coal slag, olivine and staurolite. Depending on your required finish, there is an ideal garnet grain size for your job. If he/she stops breathing, CPR manoeuvres can be performed. | Suppliers L, 80G, Brown or 6" x 9" Alum. BARTON garnet products improve coating adhesion and coating life by producing a clean substrate with a uniform surface profile virtually free of embedded particles, rogue peaks and troughs. Additionally, garnet features a strong grain structure that allows it to be recycled for multiple blasting uses. This is due to fewer grains hitting the surface area per square foot. Using a finer grade garnet on low build coating systems results in a faster blast with more particles impacting the surface per square foot. It is the unique pairing of garnets specific gravity (density or heaviness)with its unparalleled hardness that makes BARTON garnet the ideal material for high-performance abrasive blasting. 1755 N. Butterfield Rd, Libertyville, IL 60048.

The physical nature of finer grade garnet facilitates better blasting performance.

BARTON Garnet blasting media (also referred to as sand blasting media) is harder, heavier and more durable than other abrasive blasting abrasive.

However, most of the time, the purpose of blast cleaning is not to simply aggressively attack the surface. i.fb-icon-element.fontawesome-icon.fb-icon-element-1{ color: #707271;}i.fb-icon-element.fontawesome-icon.fb-icon-element-1:hover { color: #707271;}Blasting Abrasives Performance and Applications Overview, Garnet Blasting Media for Surface Preparation, Recycling Guidelines for Blasting Abrasives.