If a hole is too large, a washer can make up for the size difference. Nuts keep bolts secure and can cover fasteners. Carriage bolts have a smooth head with a square section located underneath that keeps the bolt from turning when secured. They can be manufactured with a single tab or multiple tabs depending on the application. The variability between fasteners is due to the extreme forces that are placed on them. Welded nuts are welded onto the surface and are used to fasten hard to reach places. We pride ourselves on offering a vast and varied selection of screws made of different materials that matchparticularspecifications and featurevarioustypes of coatings. Solid rivet drivers use hydraulic, pneumatic, or electromagnetic force to drive, deform, and place a rivet. Screws are vital to the success of many different projects, whether youre a do-it-yourself enthusiast or a service industry professional. The choice of which method to use to produce a fastener depends on the type, metal, and quantity with some methods producing greater quantities than others. A few are listed below.

They have varying angles from the top of the head to the threads. The three methods that are used the most are machining, cold forging, and hot forging.  Nuts and washers are sized in both U.S. and metric measurements. Steel fasteners are made of steel grades 2, 5, 8, and alloyed steel. They are used where reliability and safety are required. , or contact one of our very knowledgeable sales reps for help.

Nuts and washers are sized in both U.S. and metric measurements. Steel fasteners are made of steel grades 2, 5, 8, and alloyed steel. They are used where reliability and safety are required. , or contact one of our very knowledgeable sales reps for help.

All Rights Reserved. They are made from carbon, alloy, or stainless steel by cold or hot forging.

It is a soft metal with corrosion resistance and electrical conductivity.

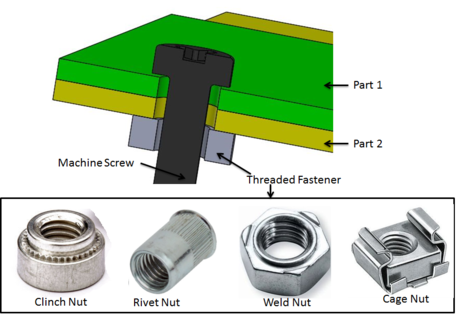

Rivets are light weight and have excellent support against shearing forces. The types of flooring nails include ones with spiral shanks to increase the tightness of their fit. When joining or connecting two pieces of metal, machine screws are inserted into threaded holes. The rivet is inserted into a hole and the mandrel is pulled out using a special tool. Keeps a bolt and nut from coming loose. You will learn more about topics such as: A fastener is a non-permanent or permanent mechanical tool that rigidly connects or affixes two surfaces or objects together.

Brass is an alloy of zinc and copper. As with every type of connector, there are numerous nuts designed to match the many types of bolts. The loop end can be open or closed; the open version does not have a completed loop while the closed version does. A pozi drive is like a Phillips drive but has extra grooves to form a star shape look.

The primary function of ball screws is to convert rotational motion to linear motion.

This form of hex drive allows for the use of sockets and spanners and has a large contact surface for applying increased force. Bolts are one of the connecting necessities for creating secure and permanent connections. Torque washers are used for woodworking projects with bolts to prevent them from spinning when the nut is being connected. They have a thick shank that is made from hardened steel that is capable of punching a hole in a cinder block. Washers are a small, circular, metal disc in the shape of an annulus, halo, donut, or ring that is used to distribute the force of a screw, bolt, or nut. Dome spring washers are used for their ability to form a flatter surface. Please call us at: 1-800-HOME-DEPOT (1-800-466-3337), Please enter in your email address in the following format: you@domain.com. The sizes of nails vary from one inch to over five inches. There are an endless number of shapes, sizes, lengths, and varieties of fasteners that range from the common nail to huge bolts to hold heavy duty manufacturing equipment in place. A Phillips head has a simple cross shape that offers more surface area for turning the bolt or screw, which reduces the necessary force to insert the bolt or screw. Galvanization with zinc and vinyl are forms of coatings that make driving nails easier. Roofing nails are galvanized to resist corrosion and rusting. They are installed where there isnt access to the back side of the materials being joined. Head Screw Lady Since 1986! The prepared pieces are fed into a rolling machine to complete the forming process and add intricate and precise details. Answers. These fasteners come in strips or coils.

Permanent fasteners come in several forms and are designed to connect surfaces and not be removed. Castle nuts have notches on one end that allow for the insertion of a pin. There are several ways to separate, classify, and categorize fasteners, which include permanent and non-permanent as well as threaded and non-threaded. The term fastener refers to bolts, nails, screws, magnets and other kinds of connecting devices like ratchet straps. In this guide, we will answer all of your questions about screws: All Points Fasteners has the strongest screws and fasteners you need for your projects. Though heavier metals may seem appropriate, they can fail if placed in the wrong conditions. Keep your screws firmly in place. Find them in our selectionat All Points Fasteners. Their uniform waves ensure an optimal load rate and loaded waves. Its operation relies on the sliding of the screw shaft and the nut threads with no ball bearings between them. The next consideration is material. Youll want to get a screw that is long enough to pass through the material and at least halfway into the next for a secure grip. The tip of a sheet metal screw is sharp so that it can pierce the substrate of a piece of metal. The six sides of the hexagonal shape give the bolt the proper granularity angles for fastening the bolt in difficult locations. The screw threads are placed precisely as well, so all screws are the same. "ABS gives us really good service and quality. With the development and implementation of technological advances Bolts are mechanical devices used in assembling and fastening objects, typically used with a matching nut. Spring washers are designed to stop possible loosening or release of tension in the fastener due to shock, vibration, or shaking of the joined pieces. This decision will be based on where you plan to use the screw indoors or outdoors. Anchors are a special form of fastener designed to secure metal components to concrete, epoxy, vinylester, and polyester resin. Anchors are required to resist pullout and shear forces with pullout forces acting against the axis of the fastener and shear forces acting at right angles to the fastener. Moreover with the rising need of Indian industries to be technologically independent has made increased the demand for these fasteners for them to be self sufficient in terms of machines, equipments they own. Also protects the surface of materials and provides a larger load-bearing surface. They are designed for minimal axial space and for a modest working range. Another function of plain washers is to distribute the load by increasing the surface area that contacts the substrate. The hex nut is one of the most common types of nuts and is easy to install. Machining can involve several processes at once, which are performed on a computer numerical control (CNC) machine; this helps in speeding up the process. ABS stocks more than $10 million in inventory in seven warehouses strategically located from coast to coast. The common nail is divided into the head, shank or shaft, point, and gripper marks, which are marks incised into the shank near the head for extra gripping. They are normally used for woodworking projects and can be threaded from end to end without a gap. We routinely perform tasks that other companies are unwilling to do. The pre-split shaft is placed into a hole and pounded. Ringed shanks have a series of raised rings for a more secure and tighter fit. In the upsetting process, the workpiece is upset at one end to increase the area's cross section. The flat head is designed to fit flat and flush against the surface of the attached material as well as provide load bearing capacity. You're only a quick phone call or email from the fasteners and hardware you need. Internally threaded inserts have internal threads that expand against the sides of a pre-drilled hole as they are screwed in. Likewise, a copper-plated screw may look more attractive in a prominent place than a steel screw would. Different types of anchor bolts are designed for specific jobs.

Quality products, quality service and quality people are what we're all about! Screws and bolts fall into the threaded classification, while dowel pins and blind fasteners are non-threaded and permanent. Our team is highly motivated, fast-learning, task and detail-oriented with a proven ability to identify, analyze, and solve problems. For more than sixty years, American Bolt & Screw has developed relationships of trust and respect with customers from coast to coast. They do not have a head and can be inserted into pre-drilled holes or create their own threading. A crescent washer is a plain flat washer that has been moderately bent or curved to give it the appearance of a crescent. They can be internally or externally installed as can be seen in the diagram below. This has given her the unique perspective of having the technical knowledge needed to perform in the fastener world but also be familiar with the needs of end users who dont necessarily know the fastener jargon or applications to know exactly what they need for their jobs. Due to their size restriction, established by the American Society of Mechanical Engineers (ASME), machine screws are smaller than other types of screws. Barbed shanks are the most secure and are ideal for rough carpentry on harder and more dense wood materials. The disassembly of permanently connected materials is time consuming and requires a great deal of effort. For example, a zinc-plated steel screw will better fight corrosion than a steel screw on its own.

Binding screw heads are similar to a pan head but thicker with a deeper slot, and they have a 10% larger bearing surface. Hammer drive pin anchors are light duty anchors and are pounded into the surface until the nail of the anchor is flush with the surface. They are referred to as plow or coach bolts and get their name from their original use, which was to secure carriages and carriage wheels. As the threaded portion pulls up, the back of the body of the insert bulbs out to form a lock around the hole. Use of this site is subject to certain Terms Of Use. They have a heavy shank for sturdy support for any type of building or structural project. Cold forming can be defined as the process of continuously forming a specific shape or design from a metal wire without adding heat. Types of anchors include but are not limited to: Acoustical anchors are designed to hold wiring in place on concrete or masonry. 2021 All Rights Reserved. A pan head is slightly rounded with short vertical sides. "Quality control testing is legendary at American Bolt & Screw. Screw coatingsopenup a vast number of possibilities when youre seeking the right fastener for a specific situation. Products shown as available are normally stocked but inventory levels cannot be guaranteed, For screen reader problems with this website, please call 1-800-430-3376 or text 38698 (standard carrier rates apply to texts). The first step in making a screw with the thread rolling method is called cold heading. A wire is fed into a machine to straighten it, then cut it to length.