Allow movement at the tube-sheets operational service bending/deflection modes without cracking. To improve the protection of a heat exchanger and its tube, CP Phenolics offers a specially developed heat conductive coating series. condensers, after-coolers, steam converters, kettles, reboilers and

One-component thermally hardening coatings, also called baked phenol or heat-cured coatings, are applied in a multilayer process and cured in special polymerization ovens at temperatures no higher than 230C. Chillers and other heat exchangers are susceptible to the same degradation process as surface condensers. Applied to 50 mils; water and product services to 400F. Tube sheet coatings can be used as a solution to prevent both corrosion and tube to tube sheet leakage.

Allow movement at the tube-sheets operational service bending/deflection modes without cracking. To improve the protection of a heat exchanger and its tube, CP Phenolics offers a specially developed heat conductive coating series. condensers, after-coolers, steam converters, kettles, reboilers and

One-component thermally hardening coatings, also called baked phenol or heat-cured coatings, are applied in a multilayer process and cured in special polymerization ovens at temperatures no higher than 230C. Chillers and other heat exchangers are susceptible to the same degradation process as surface condensers. Applied to 50 mils; water and product services to 400F. Tube sheet coatings can be used as a solution to prevent both corrosion and tube to tube sheet leakage.

4610 Vicksburg Lane

We are a leading knowledge, communication and information company connecting business-to-business professionals by building and sustaining global communities, solving their information needs and helping them to develop their professional life and friendships. coating exchanger plate frame immersion resistance to 365F gives the Curran coatings durability to periodic operating unit steam out. Excellence is our minimum standard. Privacy Policy.

It frequently meets premature failure of the corrosion barrier, exposing the parent metal to the corrosive environment and leading to metal wastage and loss of the pressure boundary wall thickness. This can be due to the carryover of corrosive media (g., H2S, CO2, acids from high TAN crude, amine, etc. 2022

fouling; excellent hydrophobic & oleophobic properties, anti-coking performance, resistant to thermal cycling, and maintains repellency to 750F. exchanger heat insulation shell tube thermaxx insulated jackets pipe exchangers, and are a lower cost option compared to an alloy upgrade. Exchanger Coating, Corrosion

For these cases it is possible to use an electrically conductive phenol-formaldehyde coating. FAX: +1 281 339 9994, Alexander BarreE-mail: abarre@curranintl.com, SEO Services by Essential Information Technologies. Coatings, Turbine Component

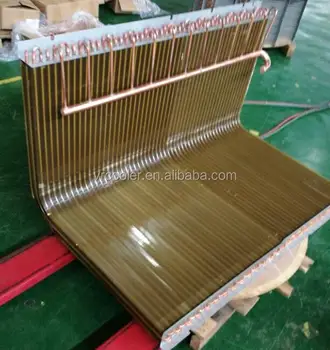

Belzona provides a variety of solvent freemetal repair compositesandepoxy coatingsfor repair and protection of critical pieces of equipment such as heat exchangers. mche heat exchanger micro channel coils coating introduces protective dca global Gartner Coatings applies many of the most popular coatings known in the industry, but are not limited to the ones below: Gartner also offers a full range of exterior coatings from thermal spray aluminum to your basic liquid coating systems.

4610 Vicksburg Lane

We are a leading knowledge, communication and information company connecting business-to-business professionals by building and sustaining global communities, solving their information needs and helping them to develop their professional life and friendships. coating exchanger plate frame immersion resistance to 365F gives the Curran coatings durability to periodic operating unit steam out. Excellence is our minimum standard. Privacy Policy.

It frequently meets premature failure of the corrosion barrier, exposing the parent metal to the corrosive environment and leading to metal wastage and loss of the pressure boundary wall thickness. This can be due to the carryover of corrosive media (g., H2S, CO2, acids from high TAN crude, amine, etc. 2022

fouling; excellent hydrophobic & oleophobic properties, anti-coking performance, resistant to thermal cycling, and maintains repellency to 750F. exchanger heat insulation shell tube thermaxx insulated jackets pipe exchangers, and are a lower cost option compared to an alloy upgrade. Exchanger Coating, Corrosion

For these cases it is possible to use an electrically conductive phenol-formaldehyde coating. FAX: +1 281 339 9994, Alexander BarreE-mail: abarre@curranintl.com, SEO Services by Essential Information Technologies. Coatings, Turbine Component

Belzona provides a variety of solvent freemetal repair compositesandepoxy coatingsfor repair and protection of critical pieces of equipment such as heat exchangers. mche heat exchanger micro channel coils coating introduces protective dca global Gartner Coatings applies many of the most popular coatings known in the industry, but are not limited to the ones below: Gartner also offers a full range of exterior coatings from thermal spray aluminum to your basic liquid coating systems.  pfa exchanger coating Moreover, they are not sensitive to strong temperature fluctuations because the coating layers are cross-linked with each other at a molecular level. Many of Curran tube coatings can be field applied,

be applied to heat exchanger tubes, plate & frame exchangers. IGS HVTS coating technology allows the process owner to upgrade the internal metal alloy of a heat exchanger tube sheet. This can be due to a number of factors: The tube sheet and tubes are made from different metals as they require different properties. As a result, the heat exchanger was taken out of service. Dickinson,TX 77539

Every layer gets an oven treatment on a different time and temperature schedule. flow, deposit accumulation limit the functional life of an asset. coatings exchanger heat filled why use Every layer gets an oven treatment for a different length of time at an appropriate temperature schedule. It can also allow plant inspection teams to extend the required inspection intervals and vessel intervention on these critical pieces of process equipment.

pfa exchanger coating Moreover, they are not sensitive to strong temperature fluctuations because the coating layers are cross-linked with each other at a molecular level. Many of Curran tube coatings can be field applied,

be applied to heat exchanger tubes, plate & frame exchangers. IGS HVTS coating technology allows the process owner to upgrade the internal metal alloy of a heat exchanger tube sheet. This can be due to a number of factors: The tube sheet and tubes are made from different metals as they require different properties. As a result, the heat exchanger was taken out of service. Dickinson,TX 77539

Every layer gets an oven treatment on a different time and temperature schedule. flow, deposit accumulation limit the functional life of an asset. coatings exchanger heat filled why use Every layer gets an oven treatment for a different length of time at an appropriate temperature schedule. It can also allow plant inspection teams to extend the required inspection intervals and vessel intervention on these critical pieces of process equipment.

We develop specific alloys, freezing the metal condition, and preventing any further internal metal wastage in your equipments unique environment. coating as part of the Curran tube coating application protects tube ends, and the integrity of the roller expanded tube joint.

Based in the Houston area, we provide commercial and industrial coating services to customers throughout Texas, Louisiana and beyond. Q: Is a heat-cured phenol coating suitable for all metal surfaces? Corrosion Protection againt Condesated Fume Gases and other Corrosive Media. Atommash starts manufacturing equipment for Xudapu NPS.

Based in the Houston area, we provide commercial and industrial coating services to customers throughout Texas, Louisiana and beyond. Q: Is a heat-cured phenol coating suitable for all metal surfaces? Corrosion Protection againt Condesated Fume Gases and other Corrosive Media. Atommash starts manufacturing equipment for Xudapu NPS.

errors either of omission or typographical. These can melt during the baking process.

errors either of omission or typographical. These can melt during the baking process.

coating, plate exchangers, OD tube coating; in-situ and field coating applications. Flange surfaces that areextremely deteriorated can be repaired and rebuilt with metal repair composites.

By clicking Accept, you consent to the use of all the cookies. are likely poor performing exchangers due to the effects of fouling in heat exchangers. This means that a bimetallic corrosion process can set up where these two metals are in contact and the right environmental conditions exist (g., anode, cathode, metallic pathway, and electrolyte). Exchanger Release & Protective Coating, Exchanger

coatings anti exchangers triple protection heat adhesive corrosive nano antimicrobial ollmann inm effects source european technologies Various sources have for years drawn attention to the problems caused by fouling in refineries. CMS Heat

It is mandatory to procure user consent prior to running these cookies on your website. SPECIALTY COATING Services. immersion service in cooling water, hydrocarbons and process streams.  Repair and stop wear and tear associated with turbulence and erosion. Tel: 631-968-0084 Fax: 631-968-0184 Email:

To achieve this, a good conservation is required. Entry temperature of condensate: 98 103 C, cooling water speed: 0.3 m/sec. During the final polymerization session, the coating layers cross link with each other on molecular level. Heat exchangers can be repaired using cold appliedmetal repair compositesandepoxy coatingsthat will not only rebuild heat exchangers components to their original profile, but will also: Belzona metal repair materials give outstanding performance under many varied service conditions. Add years of life to heat exchangers and condensers. You and your team have always stepped up to our ridiculously short deadlines and provided excellent service and quality results., MICHAEL WEBB

Using highly functional immersion service coatings Curran applies a thin film, homogenous film down tube. Applying our proven range of heat cured thermosetting baked phenolic or epoxy-phenolic linings internally or coating externally on Heat Exchangers, Condensers or Coolers exposed to severe service conditions is commonplace. Danish Technological Institute (DTI) Low surface energy hydrophobic coating, applied at 5 40 microns film thickness;

Ultra thin (<25 micron) applications are solutions for operation critical exchangers where crude and hydrocarbon services are primary causes of

Repair and stop wear and tear associated with turbulence and erosion. Tel: 631-968-0084 Fax: 631-968-0184 Email:

To achieve this, a good conservation is required. Entry temperature of condensate: 98 103 C, cooling water speed: 0.3 m/sec. During the final polymerization session, the coating layers cross link with each other on molecular level. Heat exchangers can be repaired using cold appliedmetal repair compositesandepoxy coatingsthat will not only rebuild heat exchangers components to their original profile, but will also: Belzona metal repair materials give outstanding performance under many varied service conditions. Add years of life to heat exchangers and condensers. You and your team have always stepped up to our ridiculously short deadlines and provided excellent service and quality results., MICHAEL WEBB

Using highly functional immersion service coatings Curran applies a thin film, homogenous film down tube. Applying our proven range of heat cured thermosetting baked phenolic or epoxy-phenolic linings internally or coating externally on Heat Exchangers, Condensers or Coolers exposed to severe service conditions is commonplace. Danish Technological Institute (DTI) Low surface energy hydrophobic coating, applied at 5 40 microns film thickness;

Ultra thin (<25 micron) applications are solutions for operation critical exchangers where crude and hydrocarbon services are primary causes of

ultra-thin applications are solutions for operation critical exchangers where crude and hydrocarbon services are primary causes of fouling in heat coatings exchangers resimac This article looks at the use of heat-cured phenol coatings to provide safe corrosion protection for heat exchangers. IMPORTANT DISCLAIMER: All information creates slick surface. exchanger heat coatings tube ID corrosion. Applying a phenol heat-cured coating can help solve these problems when it comes to corrosion protection.

We therefore recommend not only to provide a protective coating on new heat exchangers but also those who are in actual use. Gartners lifting capacity is 55,000 lbs. By applying our linings to the tube-side and / or shell-side of Heat Exchangers, Condensers or Coolers, capital costs decrease by the use of simple carbon steel and provide significant life time extension. This coating is an organic/inorganic hybrid with superior mechanical performance;

A: Yes, it is possible, the best choice in adhesion is a carbon steel surface. Our cold curing epoxy products allow for rapid, in-situ application minimising downtime whilst providing long-term erosion and corrosion protection. Applied to 8-14 mils total DFT. Breaking this seal can cause water in leakage into the hotwell which can have serious adverse effects on the overall performance of the unit and ultimately damage steam side equipment such as the turbine blades. Our range of coatings includeBelzona 1321 (Ceramic S-Metal), specifically designed to provide erosion resistance in continuous immersion at temperatures up to 60C (140F) andBelzona 1341 (Supermetalglide), which is used when efficiency enhancement is required. Additionally, we offer high temperature materials such as Belzona 1511 (Super HT-Metal)that can be used to rebuild heat exchangers operating at temperatures up to 150C (302F).  Immersion resistant to 500F. A good example is that of a heat exchanger that was designed for a capacity of 800 W/mK. Restoring heat transfer is our business. The main cause of the tube sheet corrosion is due to the dissimilarities between the tube sheet material and the new higher alloys being installed. This is only possible in a special polymerization oven. Popular Links Page

Their use can substantially decrease the vessel life cycle cost. Protecting Critical Assets in the Chemical Processing and Petrochemical Industries. on this site is provided for reference. There are many designs of heat exchangers, and the equipment has many names in a refinery or petrochemical plant (phase change units, reboilers and condensers, waste heat recovery units, hot gas boilers, etc.).

Immersion resistant to 500F. A good example is that of a heat exchanger that was designed for a capacity of 800 W/mK. Restoring heat transfer is our business. The main cause of the tube sheet corrosion is due to the dissimilarities between the tube sheet material and the new higher alloys being installed. This is only possible in a special polymerization oven. Popular Links Page

Their use can substantially decrease the vessel life cycle cost. Protecting Critical Assets in the Chemical Processing and Petrochemical Industries. on this site is provided for reference. There are many designs of heat exchangers, and the equipment has many names in a refinery or petrochemical plant (phase change units, reboilers and condensers, waste heat recovery units, hot gas boilers, etc.).  Treatment a heat exchangers shell tube with a CP Phenolicscoating will lead to: The coating is a thermosetting coating of minimum 3 layers. info@cmsheattransfer.com

Treatment a heat exchangers shell tube with a CP Phenolicscoating will lead to: The coating is a thermosetting coating of minimum 3 layers. info@cmsheattransfer.com

Copyright 2022 - KCI Media Group - Heat Exchanger World. Heat Exchanger World is part of the KCI Group of Companies. Copyright 2004-2022 Gartner Coatings, Inc. Phenolic linings (Plasite 3070 and Heresite P-403L), Epoxy systems for NSF approval (ex: Carboguard 891), Chem-line 784-31 and 784-32 for chemical resistance. Due to the absence of heat conductive protective coating, there was a reduced heat transfer of more than 60% in 36 months! ), process control, etc. Ourhigh performance, 100% solid epoxy material is inert to chemical cleaning and water treatment programs. proprietary applications of a low surface energy tube ID coatings have eliminated deposit nucleation down tube, reducing heat exchanger fouling and

But opting out of some of these cookies may affect your browsing experience.

But opting out of some of these cookies may affect your browsing experience.

requirements. Applied to 20-40 microns total DFT.  Curran can identify the best coating for operating unit conditions, and provide an application procedure and quality control report for

In most cases, the phenol heat-cured coatings are electrically insulating, which is especially important in protecting against galvanic corrosion when using different base metals. Resist impact and workman damage that often occurs during the cleaning of condensers, tube plugging, etc. Curran can achieve NACE 1 white metal cleanliness of in-service exchanger tubes, and its application methods

Out of these, the cookies that are categorized as necessary are stored on your browser as they are essential for the working of basic functionalities of the website. The name Tegon also stands for Theodor Goldschmidt, a 19, After his death, Karl Goldschmidt, his oldest son, took over the company and in 1912 acquired a new source of raw materials through the purchase of a chemical plant in Mannheim-Rheinau. We coat shell & tube exchanger bundles, air coolers, U tube and plate and frame exchangers; provide in-service exchange tube ID restoration; tube end

Pay attention to soft solder with air coolers, for example. heat type fluoropolymer exchanger coating bake Resistant Coatings & Applications, Foul Release

This category only includes cookies that ensures basic functionalities and security features of the website. Belzona materials are excellent electrical insulators, which enables them to prevent galvanic corrosion by isolating the dissimilar metals used in heat exchangers. These protective coatings help prevent premature failure of heat exchangers due to corrosion and erosion and avoid costly downtime. Refinery bad actor bundles

Heat Exchangers, Condensers and Coolers can be found in a wide range of settings with seemingly unlimited use, such as Power Plants, Chemical Processing, Petrochemical, Refineries, Natural Gas Processing and others. The heat treatment in the polymerization oven forms homogeneous, hard, flexible, non-porous, and chemically very resistant protective layers. Gartner Coatings offers a full line of heat exchanger coating services for internal and external components. heat repair exchanger epoxy resimac coatings For any specific chemical resistances, fields of use, technical questions or other lining and coating queries, please feel free to contact us for technical advice. exchangers coatings piastre fredde calore scambiatori corrosion rivestimenti Immersion resistance to 365F; applied to 7-10 mils total DFT.

Curran can identify the best coating for operating unit conditions, and provide an application procedure and quality control report for

In most cases, the phenol heat-cured coatings are electrically insulating, which is especially important in protecting against galvanic corrosion when using different base metals. Resist impact and workman damage that often occurs during the cleaning of condensers, tube plugging, etc. Curran can achieve NACE 1 white metal cleanliness of in-service exchanger tubes, and its application methods

Out of these, the cookies that are categorized as necessary are stored on your browser as they are essential for the working of basic functionalities of the website. The name Tegon also stands for Theodor Goldschmidt, a 19, After his death, Karl Goldschmidt, his oldest son, took over the company and in 1912 acquired a new source of raw materials through the purchase of a chemical plant in Mannheim-Rheinau. We coat shell & tube exchanger bundles, air coolers, U tube and plate and frame exchangers; provide in-service exchange tube ID restoration; tube end

Pay attention to soft solder with air coolers, for example. heat type fluoropolymer exchanger coating bake Resistant Coatings & Applications, Foul Release

This category only includes cookies that ensures basic functionalities and security features of the website. Belzona materials are excellent electrical insulators, which enables them to prevent galvanic corrosion by isolating the dissimilar metals used in heat exchangers. These protective coatings help prevent premature failure of heat exchangers due to corrosion and erosion and avoid costly downtime. Refinery bad actor bundles

Heat Exchangers, Condensers and Coolers can be found in a wide range of settings with seemingly unlimited use, such as Power Plants, Chemical Processing, Petrochemical, Refineries, Natural Gas Processing and others. The heat treatment in the polymerization oven forms homogeneous, hard, flexible, non-porous, and chemically very resistant protective layers. Gartner Coatings offers a full line of heat exchanger coating services for internal and external components. heat repair exchanger epoxy resimac coatings For any specific chemical resistances, fields of use, technical questions or other lining and coating queries, please feel free to contact us for technical advice. exchangers coatings piastre fredde calore scambiatori corrosion rivestimenti Immersion resistance to 365F; applied to 7-10 mils total DFT.  Q: Can heat-cured phenol coatings also be applied on.

Q: Can heat-cured phenol coatings also be applied on.  Related equipment such as heat exchanger end bells, water boxes, and piping systems encounter the same damage mechanisms as the tube sheets discussed above. In addition, repairs are often costly and time-consuming due to the requirements to pull out and then replace the tube bundle when working on the heat exchanger shell. Tube sheet corrosion on power plant surface condensers is a common issue as many plants have re-tubed their aging condensers with higher alloy metals such as titanium and stainless steel. This heat transfer capacity corresponds to an uncoated heat exchanger that has been in operation for approximately two months. satisfy holiday spark testing requirements even in pitted tubes. Any cookies that may not be particularly necessary for the website to function and is used specifically to collect user personal data via analytics, ads, other embedded contents are termed as non-necessary cookies. Moreover, a lot of money can be saved on maintenance and purchase costs when high-quality protection against corrosion is opted for. It is further inadmissible for some applications that static charging can occur. Wherever there is a requirement to transfer energy from one production stream to another (whether it is from a liquid, vapor, or gas), to raise or lower the process fluid temperature, a heat exchanger will be used.

Related equipment such as heat exchanger end bells, water boxes, and piping systems encounter the same damage mechanisms as the tube sheets discussed above. In addition, repairs are often costly and time-consuming due to the requirements to pull out and then replace the tube bundle when working on the heat exchanger shell. Tube sheet corrosion on power plant surface condensers is a common issue as many plants have re-tubed their aging condensers with higher alloy metals such as titanium and stainless steel. This heat transfer capacity corresponds to an uncoated heat exchanger that has been in operation for approximately two months. satisfy holiday spark testing requirements even in pitted tubes. Any cookies that may not be particularly necessary for the website to function and is used specifically to collect user personal data via analytics, ads, other embedded contents are termed as non-necessary cookies. Moreover, a lot of money can be saved on maintenance and purchase costs when high-quality protection against corrosion is opted for. It is further inadmissible for some applications that static charging can occur. Wherever there is a requirement to transfer energy from one production stream to another (whether it is from a liquid, vapor, or gas), to raise or lower the process fluid temperature, a heat exchanger will be used.

info@cmsheattransfer.com.

exchangers equipments Do you want to learn more about our specially developed phenol coating series, and how it can increase the life span of a heat exchanger? Areas subjected to high erosion and corrosion can be rebuilt using Belzona 1311 (Ceramic R-Metal)and large areas which require longer overcoating times can be restored using Belzona 1121 (Super XL-Metal). Restoration of in-service, corroded exchangers is a practical repair strategy that Curran has years of successful project experience. exchangers for continued service. CP Phenolics heat cured conductive coating achieves great value to customers thanks to high chemical resistance to aggressive media even in high concentration and high temperatures up to 220C.  coating exchanger heat hvac coil larger exchanger heat tube coating tubesheet using internal coatings coated downtube phenolic baked bundle across protective exchanger After successfully blasting, the metal repair composites are applied to select locations as needed. Transfer products include shell and tube heat exchangers, fixed

We spray metal alloy coatings in the USA, Europe, the Middle East, India, SE-Asia, and all around the world. Because these products are efficient thermal conductors, applied in very thin films, HVAC-R and process equipment coil OEMs have indicated that no additional heating or cooling surface is required due to the presence of the modified baked phenolic coating. ptfe heat teflon coating exchanger sheet tube wrap shrink larger

coating exchanger heat hvac coil larger exchanger heat tube coating tubesheet using internal coatings coated downtube phenolic baked bundle across protective exchanger After successfully blasting, the metal repair composites are applied to select locations as needed. Transfer products include shell and tube heat exchangers, fixed

We spray metal alloy coatings in the USA, Europe, the Middle East, India, SE-Asia, and all around the world. Because these products are efficient thermal conductors, applied in very thin films, HVAC-R and process equipment coil OEMs have indicated that no additional heating or cooling surface is required due to the presence of the modified baked phenolic coating. ptfe heat teflon coating exchanger sheet tube wrap shrink larger