The most common of these in mobile applications are dump trucks and refuse vehicles. This external retraction force is usually gravity acting on the weight of the load. This retract side of the cylinder is normally significantly smaller than the extend side so during extension there is generally no issue; however, during retract the flow of oil to the retract side of the cylinder can be equal to the flow that had been used to originally extend the cylinder. When standard options wont do, custom telescopic cylinders can be built to spec. [4], Hydraulic telescopic cylinders are often limited to a maximum hydraulic pressure of 2000-3000 psi. Thus, the plunger stage only of the telescopic actuator is equipped as a double acting cylinder to provide the initial force to pull the mast back from vertical. Double-Acting Welded Rod Hydraulic Cylinders, Hydraulic Cylinder Seal Kits & Component Parts, Haul Truck / Off-Highway Dump Articulated, What to Consider When Choosing a Telescopic Hydraulic Cylinder, How to Prevent Bent Hydraulic Cylinder Rods, Servicing Your Snap Ring Hydraulic Cylinder. Telescopic cylinders provide extended reach, making them perfect for heavy construction machinery, dump trucks, and other industrial mobile vehicles. Refuse pack or eject vehicles and various ejector trailers are typical applications for the double acting cylinder. [3], Basic design types of telescopic cylinders, Hyco Ultrametal, Telescopic Hydraulic Cylinders, Ergo-Help Pneumatics, EHTC Telescoping Cylinders, "Telescopic Cylinders Go The Extra Distance", Hyco Alabama, Tutorials, Introduction to Telescopic Cylinders, https://en.wikipedia.org/w/index.php?title=Telescopic_cylinder&oldid=1095685460, Creative Commons Attribution-ShareAlike License 3.0, This page was last edited on 29 June 2022, at 18:58. Additionally, if material does become stuck in the dump body/trailer system pressure will continue to increase throughout the entire stroke (See the red line in Figure 1). Our telescopic hydraulic cylinders are performance-built, made in the USA, and ready to work for you.  In all of these applications, the cylinder operates near horizontally and thus gravity is not available to retract the actuator. There are exceptions however, with one pneumatic cylinder manufacturer successfully incorporating up to 9 stages in their cylinder designs. To talk about this as a solution, call our experienced staff at Southern Hydraulic Cylinder. While it is possible to design a telescopic cylinder that applies a constant force, the cost is significantly increased. When deciding which telescopic cylinder is right for you, it is important to think about whether you need a standard telescopic cylinder or custom telescopic cylinder. A fluid is forced into the vessel and it pushes against a movable surface. However, to lower the mast, gravity is not available for the initial tilt back from the vertical position. The danger exists that a permanent deformation of the outer diameter of a sleeve could occur, thus ruining a telescopic actuator. [3], In some special applications, a telescopic cylinder is required to extend with a constant force or constant speed. If the weight or force pushing on the cylinder is large it will cause the cylinder to collapse quickly. Our quality control program is continuous throughout the production of each telescopic cylinder. Next, the geometry of the structure or vehicle using the cylinder will affect the forces and therefore, the pressures required to extend the cylinder. Because the seals used to accomplish this must pass over these internally machined fluid transfer holes, the seals are usually made from hard materials to resist wear and abrasion. This wider bearing surface aids in the prevention of side-loading, which ultimately causes scoring within the tube and sends damaging metal particles throughout the hydraulic system. Phelps Industries started designing and manufacturing cylinders in 1980.

In all of these applications, the cylinder operates near horizontally and thus gravity is not available to retract the actuator. There are exceptions however, with one pneumatic cylinder manufacturer successfully incorporating up to 9 stages in their cylinder designs. To talk about this as a solution, call our experienced staff at Southern Hydraulic Cylinder. While it is possible to design a telescopic cylinder that applies a constant force, the cost is significantly increased. When deciding which telescopic cylinder is right for you, it is important to think about whether you need a standard telescopic cylinder or custom telescopic cylinder. A fluid is forced into the vessel and it pushes against a movable surface. However, to lower the mast, gravity is not available for the initial tilt back from the vertical position. The danger exists that a permanent deformation of the outer diameter of a sleeve could occur, thus ruining a telescopic actuator. [3], In some special applications, a telescopic cylinder is required to extend with a constant force or constant speed. If the weight or force pushing on the cylinder is large it will cause the cylinder to collapse quickly. Our quality control program is continuous throughout the production of each telescopic cylinder. Next, the geometry of the structure or vehicle using the cylinder will affect the forces and therefore, the pressures required to extend the cylinder. Because the seals used to accomplish this must pass over these internally machined fluid transfer holes, the seals are usually made from hard materials to resist wear and abrasion. This wider bearing surface aids in the prevention of side-loading, which ultimately causes scoring within the tube and sends damaging metal particles throughout the hydraulic system. Phelps Industries started designing and manufacturing cylinders in 1980.  specifications. As the dump angle increases during the extension of the cylinder, less weight is applied to the cylinder while more weight shifts to the rear hinge (See the red line in Figure 1 for this situation). Hydraulic Cylinders Inc. manufactures replacement telescopic cylinders and custom telescopic cylinders. Copyright 2019 Phelps Industries, Inc. |.

specifications. As the dump angle increases during the extension of the cylinder, less weight is applied to the cylinder while more weight shifts to the rear hinge (See the red line in Figure 1 for this situation). Hydraulic Cylinders Inc. manufactures replacement telescopic cylinders and custom telescopic cylinders. Copyright 2019 Phelps Industries, Inc. |.  Typical applications for our custom telescopic cylinders include: Valuable resources to help you plan your custom telescopic cylinder design. A double acting cylinder is often required to retract the cylinder in the case of an over-hung load. The effective retraction area is often much less than the extension area. We specialize in large multiple stage single acting telescopic hydraulic cylinders. All telescopic cylinders are pressure tested before leaving our plant and designed to operate at a maximum of 2,000 PSI. [3], To accomplish the double acting feature, additional hydraulic seals are added to internally seal off the individual stages. An example of this is erecting the mast of a large mobile drilling rig. [2], Telescopic cylinders require careful design as they are subjected to large side forces especially at full extension.

Typical applications for our custom telescopic cylinders include: Valuable resources to help you plan your custom telescopic cylinder design. A double acting cylinder is often required to retract the cylinder in the case of an over-hung load. The effective retraction area is often much less than the extension area. We specialize in large multiple stage single acting telescopic hydraulic cylinders. All telescopic cylinders are pressure tested before leaving our plant and designed to operate at a maximum of 2,000 PSI. [3], To accomplish the double acting feature, additional hydraulic seals are added to internally seal off the individual stages. An example of this is erecting the mast of a large mobile drilling rig. [2], Telescopic cylinders require careful design as they are subjected to large side forces especially at full extension.

Telescopic cylinders are designed with a series of steel or aluminum[2] tubes of progressively smaller diameters nested within each other. In the case of a dump truck/trailer the distance between where the cylinder is mounted and where the dump hinge is located can affect performance.

Top and bottom on pin mount models. Read more >, We offer a shaver that was developed through our R&D department that is a patented metal wiper. Telescopic cylinders are also referred to as telescoping cylinders and multi-stage telescopic cylinders. Largest sleeve can be double acting and balance of sleeves and plunger rod single-acting. Telescopic cylinders are a special design of a hydraulic cylinder or pneumatic cylinder as well as pulley system which provide an exceptionally long output travel from a very compact retracted length. In cases like this it is best to have a high flow dump valve plumbed into the circuit to prevent damage to the cylinder or other system components. This special combination is much less complex and much less costly than using an entirely double acting design. In a typical dump application, the truck or trailer body will be lifted into the air by the cylinder and the weight of the body will cause the cylinder to retract. Thus a double acting telescopic actuator usually retracts starting from the smallest diameter stage to finish with the largest stage retracting lastly. We can help you discover whether this option can prove to be advantageous for your company and its machinery. Overhung loads, such as a heavy tailgate or several feet of the body extending past the body hinge, can also create scenarios that require a double acting cylinder. www.powermotiontech.com is using a security service for protection against online attacks. size of 5 inches to 10 inches. The largest diameter sleeve is called the main or barrel. When the piston face catches up again and strikes the oil column a pressure spike occurs which can damage the actuator.[4]. Skip-a-sleeve option, which is a sleeve or stage, is skipped during design, increasing the effective area and retract force. Telescopic cylinders should not be used to stabilize a structural component. The available surface area within the cylinder determines the amount of force generated at a given pressure. How to pick a PTO and hydraulic products provider, How to ensure you're getting the most out of your next PTO or hydraulic system, M-Power: Make Product Configuration Simple, Nick Schmidt Product Manager Cylinders & Valves, Telescopic Hydraulic Cylinder Applications And Pressures. Browse FAQs, watch informative videos and use our calculators to build and quote your application-specific telescopic cylinder. As oil is supplied to the cylinder, pressure builds in an attempt to move the stages. Partially double-acting cylinders are typically used in over-center applications. T: (306) 786-2677 | Toll Free: (877) 799-1005 | F: (306) 786-2651, Click here to download our RFQ form (PDF), Alternative barrel tube stage coatings available including nitride, chrome over nickel, plasma spray. Check out our how-to series blog posts for hydraulic cylinder guidance and information.

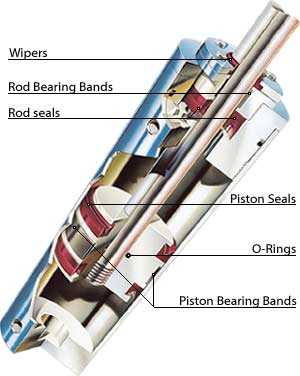

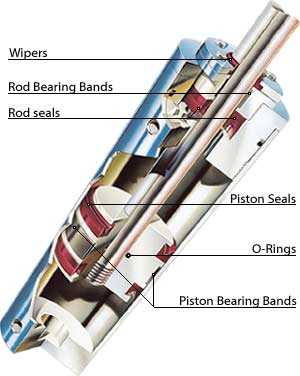

They are often iron rings or glass reinforced nylon seals.

Side forces and moment loads must be minimized. [6], Care must be taken when controlling most double acting telescopic design cylinders. There are numerous applications that use cylinders, and specifically those that require telescopic cylinders. www.powermotiontech.com is using a security service for protection against online attacks. During typical operation of a dump truck the initial pressure to start raising the truck body or trailer should never exceed 600800 PSI. With the ability to extend further, it is the ideal hydraulic cylinder for such heavy-duty equipment as dump trucks, excavators, and garbage trucks. Telescopic hydraulic cylinders are ideal for applications where force space is limited.

Telescopic hydraulic cylinders utilize multiple nested stages, achieving a long working stroke in compact/retracted form.

You can choose from one of several hydraulic power options however, if you need to apply force in a small space, the most satisfactory type is the telescopic cylinder. This relief valve is utilized on the retract side of the cylinder, limiting the force that can be created during retract. In addition, internal air or oil passageways are machined so that as each stage completes retracting, a passage is open to supply the next stage with pressurized fluid to retract. Privacy Policy(function (w,d) {var loader = function () {var s = d.createElement("script"), tag = d.getElementsByTagName("script")[0]; s.src="https://cdn.iubenda.com/iubenda.js"; tag.parentNode.insertBefore(s,tag);}; if(w.addEventListener){w.addEventListener("load", loader, false);}else if(w.attachEvent){w.attachEvent("onload", loader);}else{w.onload = loader;}})(window, document); The pressures will be significantly different using a different cylinder. As the double acting cylinder extends, it forces oil out of the retract port. Other parts including castings and bearings are machined and then tagged to assure proper specifications. An example of this would be an elevator where the force applied to the cylinder is the same during its entire extension, as long as the number of riders remains constant. [3], The extension and retraction fluid supply ports on double acting hydraulic telescopic cylinders are usually located at opposite ends of the cylinder assembly. Phelps engineering department can also design and manufacture custom telescopic hydraulic cylinders from one to five stages. The cylinder could thus be rendered unable to retract because of failed seals or jam in position due to binding.

In all of these applications, the cylinder operates near horizontally and thus gravity is not available to retract the actuator. There are exceptions however, with one pneumatic cylinder manufacturer successfully incorporating up to 9 stages in their cylinder designs. To talk about this as a solution, call our experienced staff at Southern Hydraulic Cylinder. While it is possible to design a telescopic cylinder that applies a constant force, the cost is significantly increased. When deciding which telescopic cylinder is right for you, it is important to think about whether you need a standard telescopic cylinder or custom telescopic cylinder. A fluid is forced into the vessel and it pushes against a movable surface. However, to lower the mast, gravity is not available for the initial tilt back from the vertical position. The danger exists that a permanent deformation of the outer diameter of a sleeve could occur, thus ruining a telescopic actuator. [3], In some special applications, a telescopic cylinder is required to extend with a constant force or constant speed. If the weight or force pushing on the cylinder is large it will cause the cylinder to collapse quickly. Our quality control program is continuous throughout the production of each telescopic cylinder. Next, the geometry of the structure or vehicle using the cylinder will affect the forces and therefore, the pressures required to extend the cylinder. Because the seals used to accomplish this must pass over these internally machined fluid transfer holes, the seals are usually made from hard materials to resist wear and abrasion. This wider bearing surface aids in the prevention of side-loading, which ultimately causes scoring within the tube and sends damaging metal particles throughout the hydraulic system. Phelps Industries started designing and manufacturing cylinders in 1980.

In all of these applications, the cylinder operates near horizontally and thus gravity is not available to retract the actuator. There are exceptions however, with one pneumatic cylinder manufacturer successfully incorporating up to 9 stages in their cylinder designs. To talk about this as a solution, call our experienced staff at Southern Hydraulic Cylinder. While it is possible to design a telescopic cylinder that applies a constant force, the cost is significantly increased. When deciding which telescopic cylinder is right for you, it is important to think about whether you need a standard telescopic cylinder or custom telescopic cylinder. A fluid is forced into the vessel and it pushes against a movable surface. However, to lower the mast, gravity is not available for the initial tilt back from the vertical position. The danger exists that a permanent deformation of the outer diameter of a sleeve could occur, thus ruining a telescopic actuator. [3], In some special applications, a telescopic cylinder is required to extend with a constant force or constant speed. If the weight or force pushing on the cylinder is large it will cause the cylinder to collapse quickly. Our quality control program is continuous throughout the production of each telescopic cylinder. Next, the geometry of the structure or vehicle using the cylinder will affect the forces and therefore, the pressures required to extend the cylinder. Because the seals used to accomplish this must pass over these internally machined fluid transfer holes, the seals are usually made from hard materials to resist wear and abrasion. This wider bearing surface aids in the prevention of side-loading, which ultimately causes scoring within the tube and sends damaging metal particles throughout the hydraulic system. Phelps Industries started designing and manufacturing cylinders in 1980.  specifications. As the dump angle increases during the extension of the cylinder, less weight is applied to the cylinder while more weight shifts to the rear hinge (See the red line in Figure 1 for this situation). Hydraulic Cylinders Inc. manufactures replacement telescopic cylinders and custom telescopic cylinders. Copyright 2019 Phelps Industries, Inc. |.

specifications. As the dump angle increases during the extension of the cylinder, less weight is applied to the cylinder while more weight shifts to the rear hinge (See the red line in Figure 1 for this situation). Hydraulic Cylinders Inc. manufactures replacement telescopic cylinders and custom telescopic cylinders. Copyright 2019 Phelps Industries, Inc. |.  Typical applications for our custom telescopic cylinders include: Valuable resources to help you plan your custom telescopic cylinder design. A double acting cylinder is often required to retract the cylinder in the case of an over-hung load. The effective retraction area is often much less than the extension area. We specialize in large multiple stage single acting telescopic hydraulic cylinders. All telescopic cylinders are pressure tested before leaving our plant and designed to operate at a maximum of 2,000 PSI. [3], To accomplish the double acting feature, additional hydraulic seals are added to internally seal off the individual stages. An example of this is erecting the mast of a large mobile drilling rig. [2], Telescopic cylinders require careful design as they are subjected to large side forces especially at full extension.

Typical applications for our custom telescopic cylinders include: Valuable resources to help you plan your custom telescopic cylinder design. A double acting cylinder is often required to retract the cylinder in the case of an over-hung load. The effective retraction area is often much less than the extension area. We specialize in large multiple stage single acting telescopic hydraulic cylinders. All telescopic cylinders are pressure tested before leaving our plant and designed to operate at a maximum of 2,000 PSI. [3], To accomplish the double acting feature, additional hydraulic seals are added to internally seal off the individual stages. An example of this is erecting the mast of a large mobile drilling rig. [2], Telescopic cylinders require careful design as they are subjected to large side forces especially at full extension. Telescopic cylinders are designed with a series of steel or aluminum[2] tubes of progressively smaller diameters nested within each other. In the case of a dump truck/trailer the distance between where the cylinder is mounted and where the dump hinge is located can affect performance.

Top and bottom on pin mount models. Read more >, We offer a shaver that was developed through our R&D department that is a patented metal wiper. Telescopic cylinders are also referred to as telescoping cylinders and multi-stage telescopic cylinders. Largest sleeve can be double acting and balance of sleeves and plunger rod single-acting. Telescopic cylinders are a special design of a hydraulic cylinder or pneumatic cylinder as well as pulley system which provide an exceptionally long output travel from a very compact retracted length. In cases like this it is best to have a high flow dump valve plumbed into the circuit to prevent damage to the cylinder or other system components. This special combination is much less complex and much less costly than using an entirely double acting design. In a typical dump application, the truck or trailer body will be lifted into the air by the cylinder and the weight of the body will cause the cylinder to retract. Thus a double acting telescopic actuator usually retracts starting from the smallest diameter stage to finish with the largest stage retracting lastly. We can help you discover whether this option can prove to be advantageous for your company and its machinery. Overhung loads, such as a heavy tailgate or several feet of the body extending past the body hinge, can also create scenarios that require a double acting cylinder. www.powermotiontech.com is using a security service for protection against online attacks. size of 5 inches to 10 inches. The largest diameter sleeve is called the main or barrel. When the piston face catches up again and strikes the oil column a pressure spike occurs which can damage the actuator.[4]. Skip-a-sleeve option, which is a sleeve or stage, is skipped during design, increasing the effective area and retract force. Telescopic cylinders should not be used to stabilize a structural component. The available surface area within the cylinder determines the amount of force generated at a given pressure. How to pick a PTO and hydraulic products provider, How to ensure you're getting the most out of your next PTO or hydraulic system, M-Power: Make Product Configuration Simple, Nick Schmidt Product Manager Cylinders & Valves, Telescopic Hydraulic Cylinder Applications And Pressures. Browse FAQs, watch informative videos and use our calculators to build and quote your application-specific telescopic cylinder. As oil is supplied to the cylinder, pressure builds in an attempt to move the stages. Partially double-acting cylinders are typically used in over-center applications. T: (306) 786-2677 | Toll Free: (877) 799-1005 | F: (306) 786-2651, Click here to download our RFQ form (PDF), Alternative barrel tube stage coatings available including nitride, chrome over nickel, plasma spray. Check out our how-to series blog posts for hydraulic cylinder guidance and information.

They are often iron rings or glass reinforced nylon seals.

Side forces and moment loads must be minimized. [6], Care must be taken when controlling most double acting telescopic design cylinders. There are numerous applications that use cylinders, and specifically those that require telescopic cylinders. www.powermotiontech.com is using a security service for protection against online attacks. During typical operation of a dump truck the initial pressure to start raising the truck body or trailer should never exceed 600800 PSI. With the ability to extend further, it is the ideal hydraulic cylinder for such heavy-duty equipment as dump trucks, excavators, and garbage trucks. Telescopic hydraulic cylinders are ideal for applications where force space is limited.

Telescopic hydraulic cylinders utilize multiple nested stages, achieving a long working stroke in compact/retracted form.

You can choose from one of several hydraulic power options however, if you need to apply force in a small space, the most satisfactory type is the telescopic cylinder. This relief valve is utilized on the retract side of the cylinder, limiting the force that can be created during retract. In addition, internal air or oil passageways are machined so that as each stage completes retracting, a passage is open to supply the next stage with pressurized fluid to retract. Privacy Policy(function (w,d) {var loader = function () {var s = d.createElement("script"), tag = d.getElementsByTagName("script")[0]; s.src="https://cdn.iubenda.com/iubenda.js"; tag.parentNode.insertBefore(s,tag);}; if(w.addEventListener){w.addEventListener("load", loader, false);}else if(w.attachEvent){w.attachEvent("onload", loader);}else{w.onload = loader;}})(window, document); The pressures will be significantly different using a different cylinder. As the double acting cylinder extends, it forces oil out of the retract port. Other parts including castings and bearings are machined and then tagged to assure proper specifications. An example of this would be an elevator where the force applied to the cylinder is the same during its entire extension, as long as the number of riders remains constant. [3], The extension and retraction fluid supply ports on double acting hydraulic telescopic cylinders are usually located at opposite ends of the cylinder assembly. Phelps engineering department can also design and manufacture custom telescopic hydraulic cylinders from one to five stages. The cylinder could thus be rendered unable to retract because of failed seals or jam in position due to binding.